Growth method capable of effectively reducing silicon carbide epitaxial surface defects

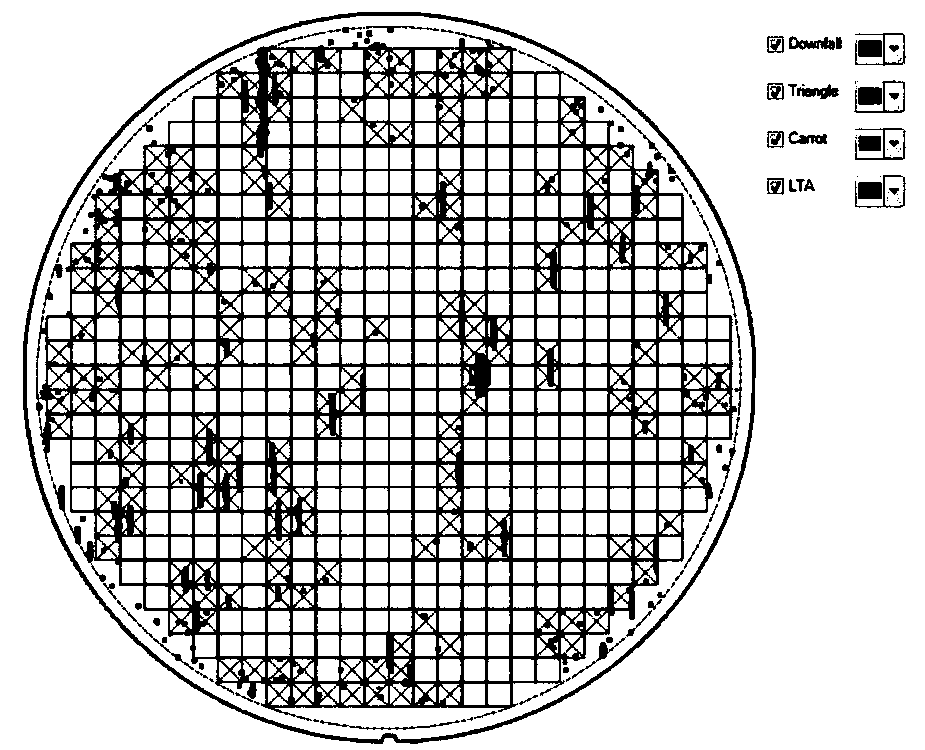

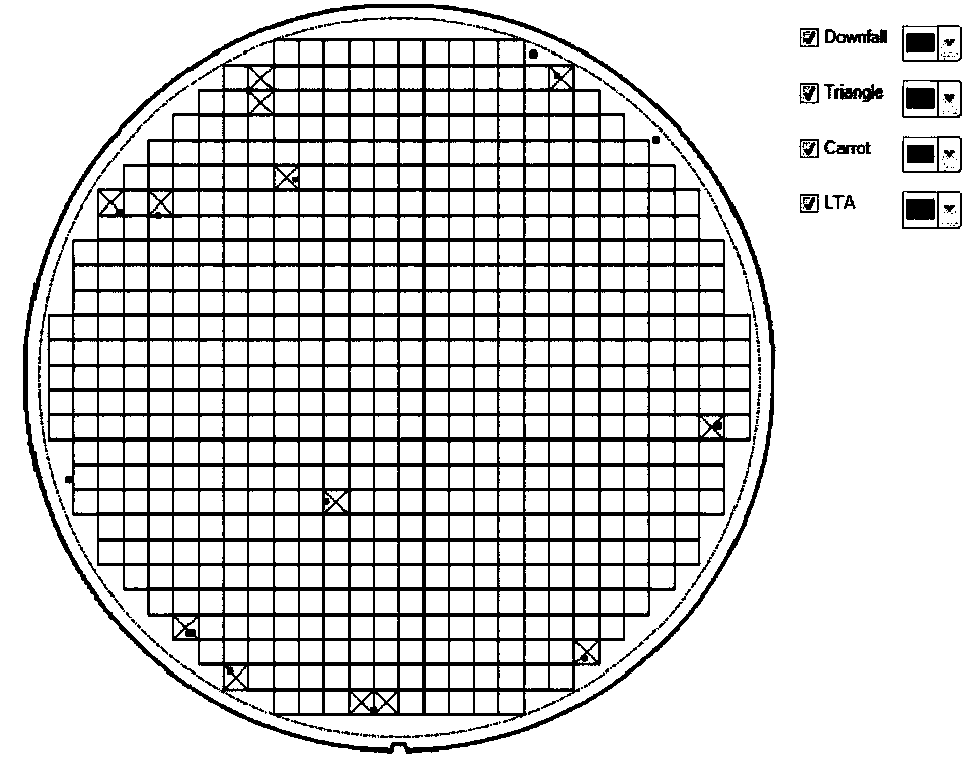

A growth method and epitaxial growth technology are applied in the growth field that can effectively reduce the surface defects of silicon carbide epitaxy, and can solve the problems of low device production yield, many surface defects of SiC epitaxial wafers, hindering the promotion and application of SiC materials, etc. The effect of reducing surface defects and high promotion value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

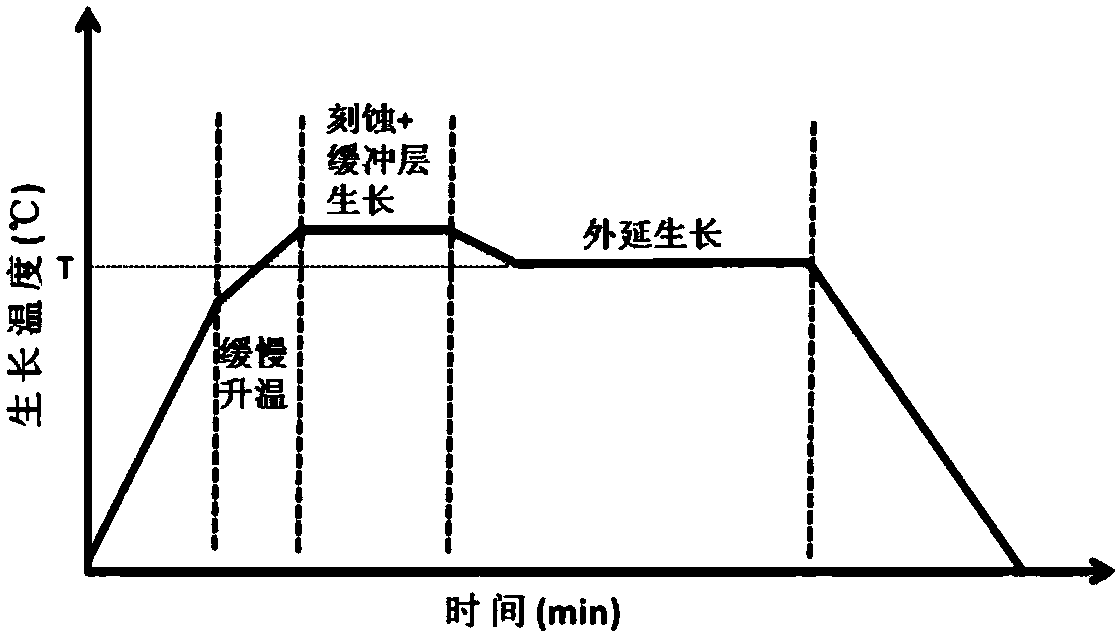

[0020] The provided silicon carbide film growth method using silane+propane+hydrogen chloride comprises the following steps:

[0021] Step 1: Select a silicon carbide substrate with a silicon surface that is 4° to the direction, and place the substrate in a graphite base after standard cleaning;

[0022] Step 2: Put the graphite base into the reaction chamber, replace the air with argon, pump the reaction chamber to a vacuum, and then pass hydrogen gas into the reaction chamber to keep the H 2 The flow rate is 160L / min, the pressure of the reaction chamber is 100mbar, and the reaction chamber is heated from room temperature to 1400°C at a fixed heating rate of 25°C / min by radio frequency heating; then the heating rate is reduced to 15°C / min, and the temperature is raised to 1580°C, constant temperature etching for 10 minutes;

[0023] The third step: pass silane (SiH 4 )+propane+(C 3 h 8 ) + hydrogen chloride (HCl) mixed gas, set the silane flow rate to 50 sccm, C / Si to 0...

Embodiment 2

[0027] The provided silicon carbide film growth method using silane+propane+hydrogen chloride comprises the following steps:

[0028] Step 1: Select a silicon carbide substrate with a silicon surface that is 4° to the direction, and place the substrate in a graphite base after standard cleaning;

[0029] Step 2: Put the graphite base into the reaction chamber, replace the air with argon, pump the reaction chamber to a vacuum, and then pass hydrogen gas into the reaction chamber to keep the H 2 The flow rate is 180L / min, the pressure of the reaction chamber is 150mbar, and the reaction chamber is heated from room temperature to 1400°C at a fixed heating rate of 30°C / min by radio frequency heating; then the heating rate is reduced to 15°C / min, and the temperature is raised to 1570°C, constant temperature etching for 11 minutes;

[0030] The third step: pass silane (SiH 4 )+propane+(C 3 h 8 ) + hydrogen chloride (HCl) mixed gas, set the silane flow rate to 50sccm, C / Si to 1....

Embodiment 3

[0034] The provided silicon carbide film growth method using silane+propane+hydrogen chloride comprises the following steps:

[0035] Step 1: Select a silicon carbide substrate with a silicon surface that is 4° to the direction, and place the substrate in a graphite base after standard cleaning;

[0036]Step 2: Put the graphite base into the reaction chamber, replace the air with argon, pump the reaction chamber to a vacuum, and then pass hydrogen gas into the reaction chamber to keep the H 2 The flow rate is 180L / min, the pressure of the reaction chamber is 150mbar, and the reaction chamber is heated from room temperature to 1400°C at a fixed heating rate of 30°C / min by radio frequency heating; then the heating rate is reduced to 15°C / min, and the temperature is raised to 1560°C, constant temperature etching for 12 minutes;

[0037] The third step: pass silane (SiH 4 )+propane+(C 3 h 8 ) + hydrogen chloride (HCl) mixed gas, set the silane flow to 100sccm, C / Si to 1.2, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com