Fixed bed filtering unit and water treatment device

A technology of water treatment device and filter unit, which is applied in the direction of filter circuit, filter separation, gravity filter, etc., which can solve the problems of weak ability to intercept suspended solids, many water leakage points, large fixed bed volume, etc., and achieve improved electrochemical performance. Reaction speed or micropore adsorption speed, strong positive flushing and backwashing effects, and the effect of increasing the electrochemical reaction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

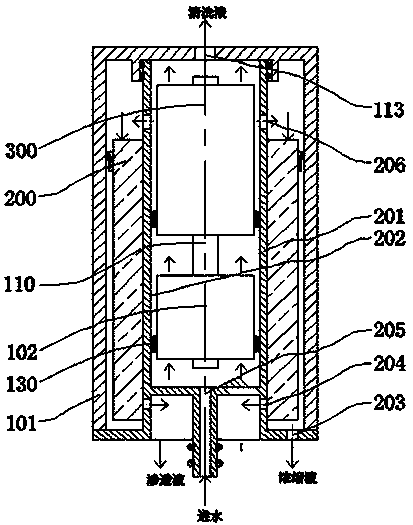

[0098] Example 1, such as figure 1 As shown in the water treatment device of the present invention, the water treatment device includes a fixed bed filter unit and a membrane separation unit connected in series, and the membrane separation unit includes a membrane separation unit 200 and a membrane separation unit 300 with different separation precisions, The membrane separation unit 300 and the fixed bed layer 102 are arranged in series outside the mandrel 110 and then set in the D cavity 202 of the water collection pipe 210 of the membrane separation unit 200, and pass through the water collection pipe 210 and the end face and axial direction of the membrane separation unit 200. It is fixedly connected to the housing 101. Preferably, as Figure 20 , Figure 21 and Figure 23 As shown, the fixed bed layer 102 involved in the present invention may be a single layer of filter media particles 103 , may also include a turbulence promotion layer 104 , or may be a multi-layer co...

Embodiment 2

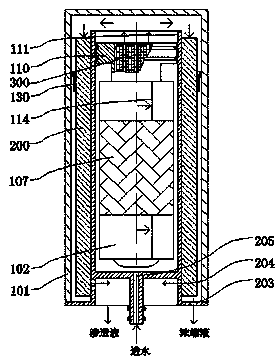

[0099] Embodiment 2, as figure 2 In another water treatment device of the present invention shown, the water treatment device is respectively provided with a membrane separation unit 300, a fixed bed 102 and a membrane separation unit 200 according to the radial direction from inside to outside, and the membrane separation unit 300 is located at In the C cavity 111 of the mandrel 110 of the fixed bed layer 102, the fixed bed layer 102 is arranged in the D cavity 202 of the water collection pipe 201 of the membrane separation unit 200, and the fixed bed layer 102 is circumferentially fixed in the D cavity of the water collection pipe 201. chamber 202. Such as Figure 22 and Figure 12 As shown, the fixed bed 102 of this embodiment includes filter medium particles 103, turbulence-promoting layer 104, support layer 105, mandrel 110 and water inlet 114, and the water inlet 114 is located in the circumferential direction of the fixed bed 102, and the support layer 105 is tubula...

Embodiment 3

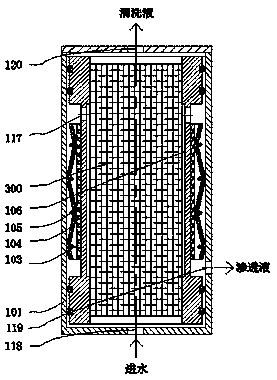

[0100] Embodiment 3, as image 3 As shown in another water treatment device of the present invention, the housing 101 of the water treatment device is provided with a fixed bed 102 and a membrane separation unit 300, and the membrane separation unit 300 is arranged on the support layer 105 of the fixed bed 102 In cavity A 106 of A, the fixed bed 102 is circumferentially fixed in the casing 101 . The fixed bed 102 of this embodiment can be selected as Figure 13-21 and Figure 23 The single-layer or multi-layer composite fixed bed of water treatment media shown can be composited on support layers 105 of different structures. When producing produced water, the liquid to be treated flows in from the E diversion hole 118, is pretreated by the membrane separation unit, flows from the D diversion hole 117 into the fixed bed 102 for purification, and then is exported from the F diversion hole 119. The hydraulic flushing in this embodiment includes forward flushing and backwashing....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com