Preparation method of magnetic gel heavy metal adsorbent

A heavy metal and adsorbent technology, applied in the field of water pollution treatment, can solve the problems of high operating cost, high energy consumption, secondary pollution, etc., and achieve the effects of fewer types of raw materials, simple preparation method, and easy separation and purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

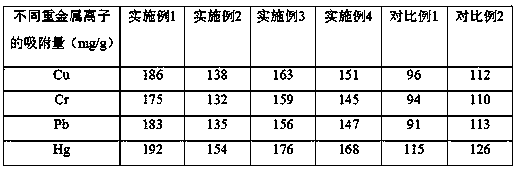

Examples

Embodiment 1

[0024] A preparation method of a magnetic gel heavy metal adsorbent, the specific steps of the preparation method are as follows:

[0025] (1) Fe 3 o 4 Preparation of Magnetic Nanoparticles

[0026] Preparation of Fe by microemulsion method 3 o 4 Magnetic nanoparticles, and drying the magnetic nanoparticles in an oven;

[0027] (2) Weigh 35 mg of Fe prepared in step (1) 3 o 4 For magnetic nanoparticles, resuspend the magnetic nanoparticles with 15 mL of aqueous solution and place them on an ultrasonic instrument for ultrasonic dispersion for 15 minutes, then add glutaraldehyde solution to it, the final concentration of glutaraldehyde solution is 0.8M, and place the magnetic nanoparticles at room temperature. The nanoparticles are fully stirred evenly;

[0028] (3) Weigh 22 mg of sodium alginate and fully dissolve it with 15 mL of acetic acid with a volume concentration of 15% to obtain a sodium alginate solution, and add the sodium alginate solution to the magnetic nano...

Embodiment 2

[0032] A preparation method of a magnetic gel heavy metal adsorbent, the specific steps of the preparation method are as follows:

[0033] (1) Fe 3 o 4 Preparation of Magnetic Nanoparticles

[0034] Preparation of Fe by microemulsion method 3 o 4 Magnetic nanoparticles, and drying the magnetic nanoparticles in an oven;

[0035] (2) Weigh 20 mg of Fe prepared in step (1) 3 o 4 For magnetic nanoparticles, resuspend the magnetic nanoparticles with 10 mL of aqueous solution and place them on an ultrasonic instrument for ultrasonic dispersion for 10 minutes, then add glutaraldehyde solution to it, the final concentration of glutaraldehyde solution is 0.5M, and place the magnetic nanoparticles at room temperature. The nanoparticles are fully stirred evenly;

[0036] (3) Weigh 15 mg of sodium alginate and fully dissolve it with 10 mL of acetic acid with a volume concentration of 10% to obtain a sodium alginate solution, and add the sodium alginate solution to the magnetic nano...

Embodiment 3

[0040] A preparation method of a magnetic gel heavy metal adsorbent, the specific steps of the preparation method are as follows:

[0041] (1) Fe 3 o 4 Preparation of Magnetic Nanoparticles

[0042] Preparation of Fe by microemulsion method 3 o 4 magnetic nanoparticles, and dry the magnetic nanoparticles in an oven;

[0043] (2) Weigh 50 mg of Fe prepared in step (1) 3 o 4For magnetic nanoparticles, resuspend the magnetic nanoparticles with 20mL of aqueous solution and place them on an ultrasonic instrument for ultrasonic dispersion for 20min, then add glutaraldehyde solution to it, the final concentration of the glutaraldehyde solution is 1M, and dissolve the magnetic nanoparticles at room temperature. The particles are fully stirred evenly;

[0044] (3) Weigh 30 mg of sodium alginate and fully dissolve it with 20 mL of acetic acid with a volume concentration of 20% to obtain a sodium alginate solution, and add the sodium alginate solution to the magnetic nanoparticles...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com