Lithium bromide absorption type refrigerating unit driven by waste heat of internal combustion engine and control method

An absorption refrigeration, lithium bromide technology, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of difficult space application, large power consumption, complex system, etc., to avoid liquid short circuit phenomenon, reduce system power consumption The effect of simplifying the system and piping layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

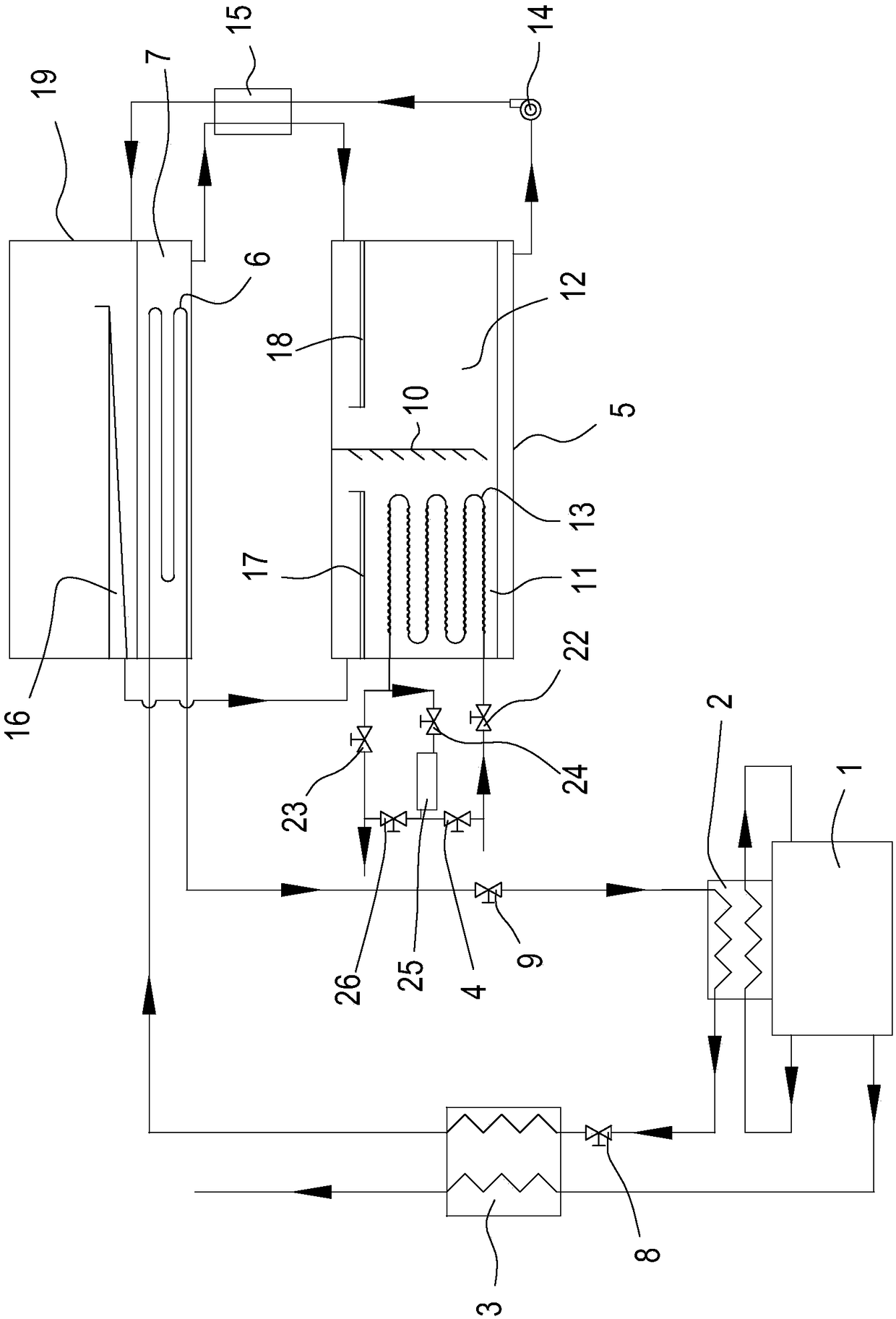

[0035] Such as figure 1 As shown, a lithium bromide absorption refrigeration unit driven by waste heat of an internal combustion engine includes an internal combustion engine 1 and a cylinder liner heat exchanger 2 connected to the internal combustion engine 1, the internal combustion engine 1 is connected to the flue gas heat exchanger 3, and also includes a condensation generator 19 and an evaporation absorber 5. The condensation generator 19 includes a generator 7 with a first heat exchange coil 6, the cylinder liner heat exchanger 2 is connected to the flue gas heat exchanger 3 through the first electromagnetic valve 8, and the flue gas heat exchanger 3 is connected to The first heat exchange coil 6, the first heat exchange coil is connected to the cylinder liner heat exchanger 2 through the second solenoid valve 9,

[0036] The evaporation absorber 5 is divided into an evaporation chamber 11 and an absorption chamber 12 with a partition plate 10. The evaporation chamber 1...

Embodiment 2

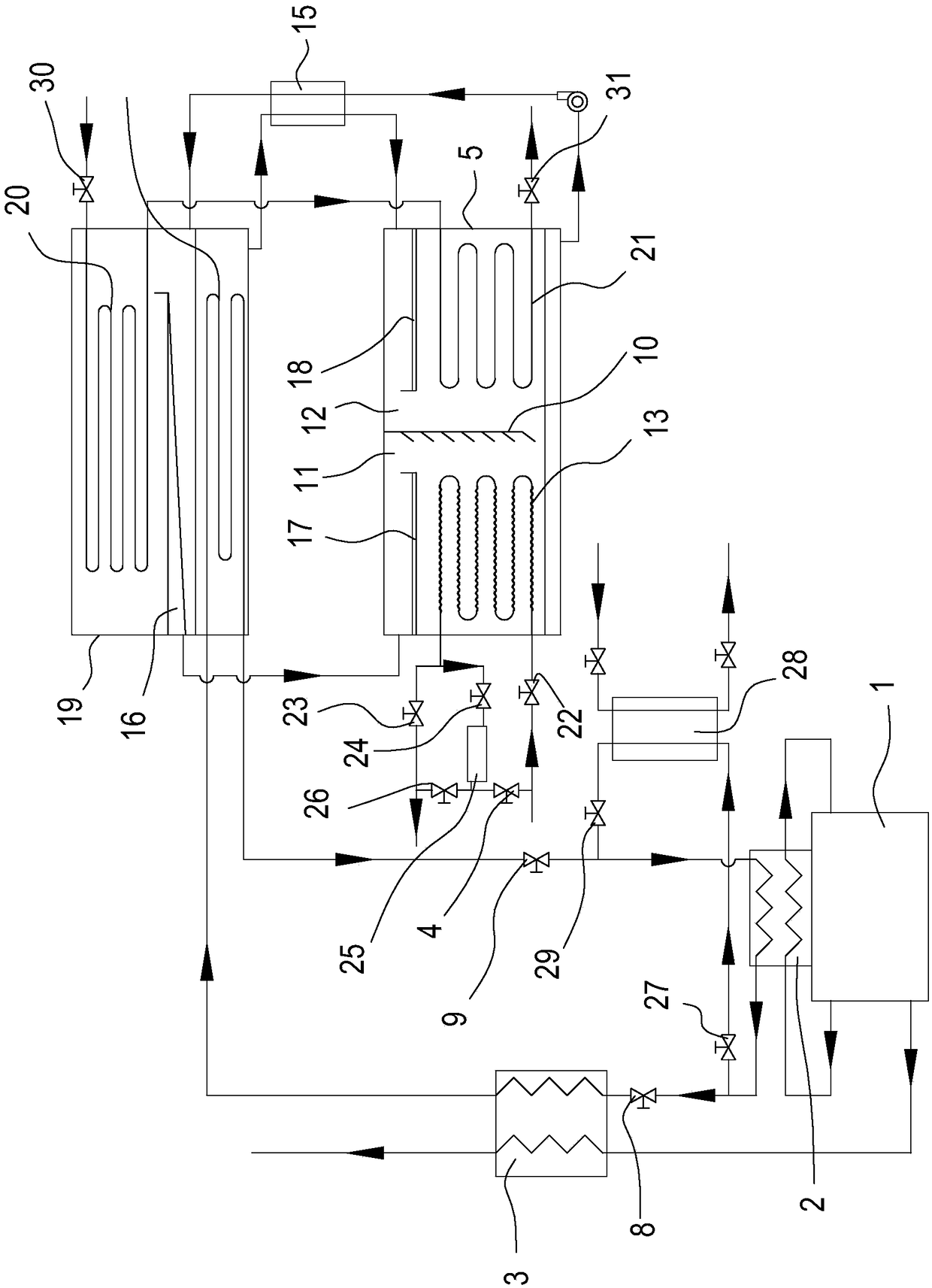

[0041] The structure and working principle of this embodiment are basically the same as that of Embodiment 1, the difference is that in combination figure 2 as shown,

[0042] In the condensation generator 19 and above the first heat exchange coil 6, a liquid collector 16 is provided, in the evaporation chamber 11 and above the second heat exchange coil 13, a condensed water distributor 17 is provided, and in the absorption chamber 12, a liquid collector 16 is provided. There is lithium bromide solution distributor 18.

[0043] The liquid collector 16 is a plate-shaped structure with an inclined bottom, which is used to collect steam condensed water. The condensed water distributor 17 and the lithium bromide solution distributor 18 can use a plate with holes at the bottom to achieve a uniform shower effect. Of course, corresponding deformations can also be made to the above structure.

[0044] The liquid collector 16 is connected to the condensed water distributor 17, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com