Fireproof cable used for firefighting

A cable and fire-fighting technology, which is applied in the field of fire-resistant cables for fire-fighting, can solve the problems of easy deformation and aging of cables, achieve excellent heat insulation performance and electrical insulation ability, good mechanical toughness, and improve the effect of tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

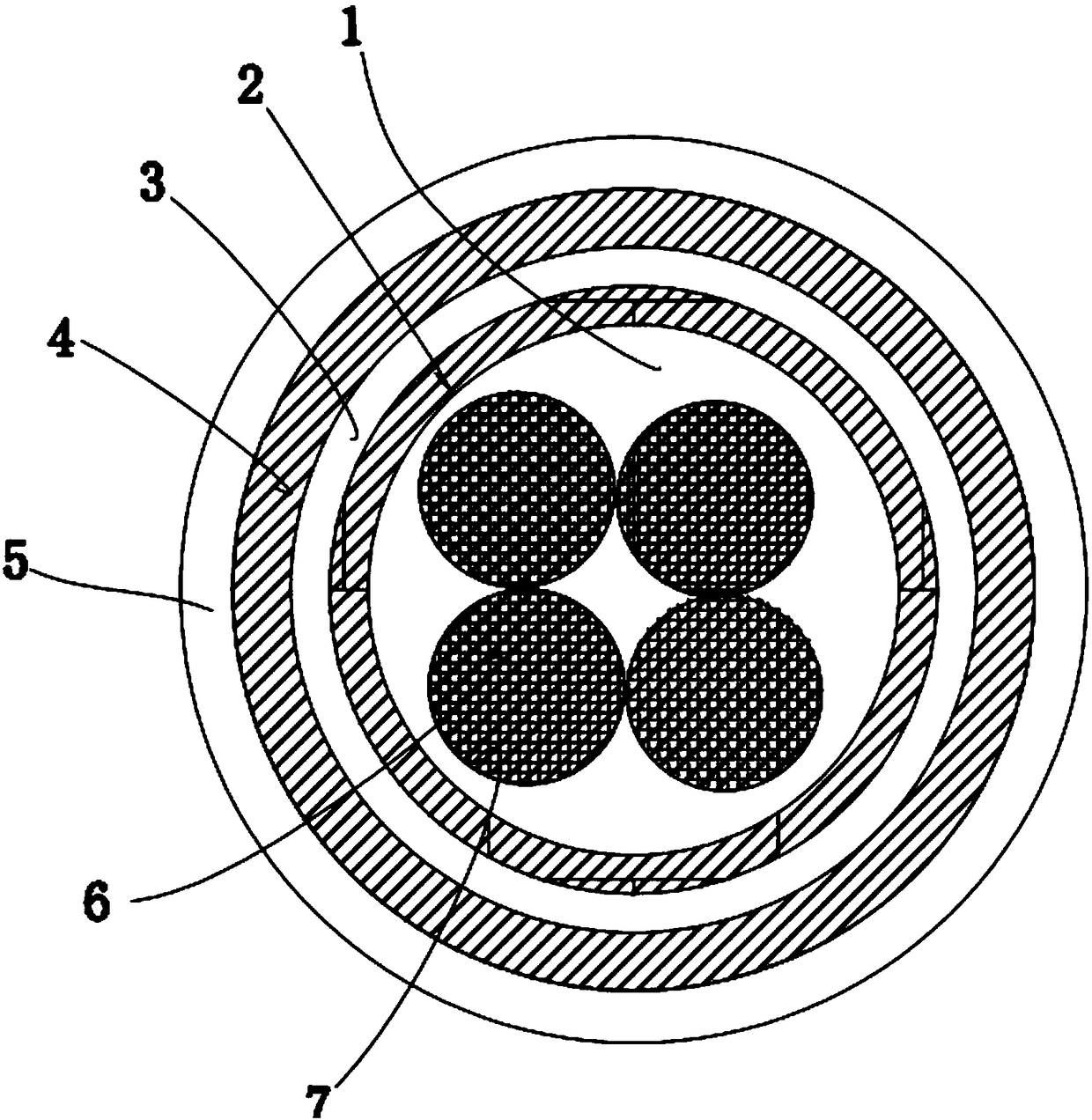

[0021] Please refer to the attached figure 1 , which discloses an embodiment 1 of the present invention, including a cable core 1, a high temperature resistant insulating layer 2, an aluminum metal sheath 3, an epoxy / benzoxazine resin-based fire-resistant inner sheath 4 and a low-smoke halogen-free polyolefin outer sheath 5.

[0022] High temperature resistant insulating layer 2 is made of 45 parts of mica powder, 20 parts of glass fiber, 15 parts of polytetrafluoroethylene modified phenolic compression molding powder and 5 parts of Mg(OH) 2 made.

[0023] Three copper wires are twisted with each other and wrapped in ceramic silicone rubber 7 to form an insulated conductor 6. The ceramic silicone rubber solidifies into a hard ceramic body under high temperature conditions, shields the internal conductor, and keeps the cable at 950°C-1000°C Under high temperature, it can maintain a working time of more than 90 minutes, so that the power transmission at the fire scene is smoot...

Embodiment 2

[0025] Please refer to the attached figure 1 , which discloses the embodiment 2 of the present invention, the present embodiment is similar to the embodiment 1, the difference is that the high temperature resistant insulating layer (2) is made of 55 parts of mica powder, 30 parts of glass fiber, 25 parts of polytetrafluoroethylene modified phenolic pressed plastic powder and 10 parts Mg(OH) 2 Made with a thickness of 3mm, the insulated conductor is made by twisting eight copper wires.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com