Fermented soybean milk and production method thereof

A technology for fermented yogurt and a production method is applied in the field of fermented yogurt and its production, and achieves the effects of rich bean flavor, avoiding whey precipitation, and shortening production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

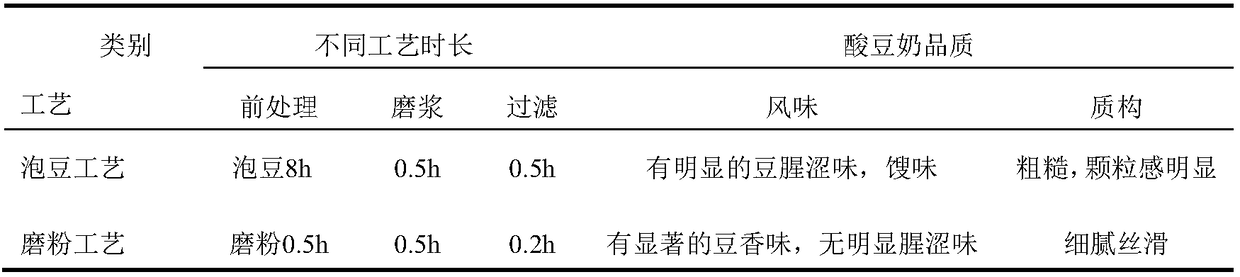

Method used

Image

Examples

Embodiment 1

[0026] A production method of fermented soy milk, comprising the following steps:

[0027] (1) Microwave ripening and peeling selected soybean raw materials;

[0028] (2) Utilize the ultrafine pulverizer to carry out ultrafine pulverization to the dehulled beans, and pass through a 300-mesh sieve to obtain soybean powder;

[0029] (3) Mix 8% soy flour with 0.056% baking soda, soak in 6 times the volume of 90°C water for 0.5h;

[0030] (4) rough grinding, fine grinding, cross 100 mesh sieves;

[0031] (5) add sucrose, glucose, pectin composite stabilizer, dissolving deployment, the weight percent of described sucrose, pectin composite stabilizer is: sucrose 8%, glucose 2%, pectin composite stabilizer 0.35%; Wherein, fruit The glue compound stabilizer comprises the following components according to mass percentage: 37% of pectin, 30% of acetylated distarch phosphate, 15% of carrageenan, 10% of gelatin, and 8% of mono-diglyceride.

[0032] (6) Stir the prepared mixed solution ...

Embodiment 2

[0037] A production method of fermented soy milk, comprising the following steps:

[0038] (1) Microwave ripening and peeling selected soybean raw materials;

[0039] (2) Utilize the ultrafine pulverizer to carry out ultrafine pulverization to the dehulled beans, and pass through a 300-mesh sieve to obtain soybean powder;

[0040] (3) Mix 8% soy flour with 0.056% baking soda, soak in 6 times the volume of 90°C water for 0.5h;

[0041] (4) rough grinding, fine grinding, cross 100 mesh sieves;

[0042] (5) add sucrose, glucose, pectin composite stabilizer, dissolving deployment, the weight percent of described sucrose, pectin composite stabilizer is: sucrose 8%, glucose 2%, pectin composite stabilizer 0.35%; Wherein, fruit The glue compound stabilizer comprises the following components according to mass percentage: 37% of pectin, 30% of acetylated distarch phosphate, 15% of carrageenan, 10% of gelatin, and 8% of mono-diglyceride.

[0043] (6) Stir the prepared mixed solution ...

Embodiment 3

[0048] A production method of fermented soy milk, comprising the following steps:

[0049] (1) Microwave ripening and peeling selected soybean raw materials;

[0050] (2) Utilize the ultrafine pulverizer to carry out ultrafine pulverization to the dehulled beans, and pass through a 300-mesh sieve to obtain soybean powder;

[0051] (3) Mix 8% soy flour with 0.056% baking soda, soak in 6 times the volume of 90°C water for 0.5h;

[0052] (4) rough grinding, fine grinding, cross 100 mesh sieves;

[0053] (5) add sucrose, glucose, pectin composite stabilizer, dissolving deployment, the weight percent of described sucrose, pectin composite stabilizer is: sucrose 8%, glucose 2%, pectin composite stabilizer 0.35%; Wherein, fruit The glue compound stabilizer comprises the following components according to mass percentage: 37% of pectin, 30% of acetylated distarch phosphate, 15% of carrageenan, 10% of gelatin, and 8% of mono-diglyceride.

[0054] (6) Stir the prepared mixed solution ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com