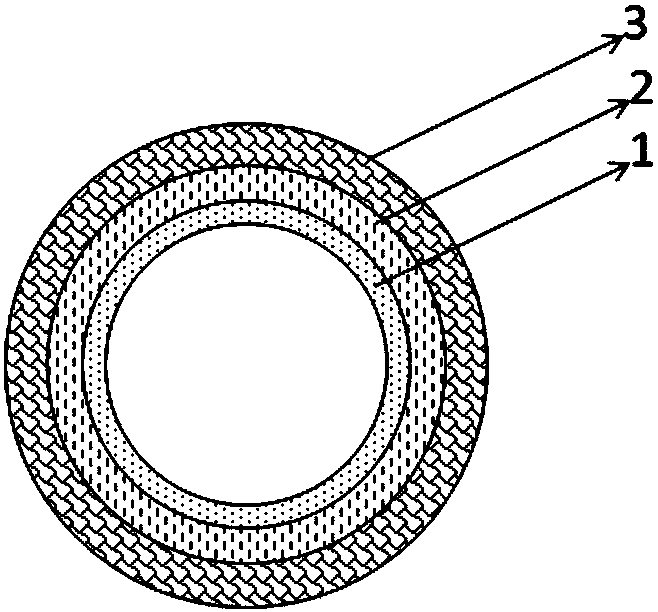

Three-layer structural composite artificial blood vessel

An artificial blood vessel, three-layer structure technology, applied in the field of medical devices, can solve the problems of restricting the fusion of vascular prostheses, low blood permeation, and difficulty in fully growing cells into the tube wall, etc., achieving good repeatability, promoting integration, and good The effect of the application foreground

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Please refer to figure 2 , a straight three-layer structure artificial blood vessel, the inner diameter of the blood vessel is 5mm, the length is 45cm, and the thickness of the tube wall is 487 microns. Tube wall thickness refers to the total thickness of dense hemostatic layer 1, elastomer layer 2, and fiber-reinforced layer 3.

[0021] The thickness of the artificial blood vessel wall and the thickness of each layer of the wall are measured by a thickness gauge at a pressure of 17.5kPa and a presser foot area of 50mm. 2 Test under certain conditions: Measure a point every 2cm in the horizontal direction, measure 5 points in total, and calculate the average value of all measurement points. The porosity of each layer is tested by the method of liquid substitution: use ethanol as the substitution liquid, put the material into a known volume (V 1 ) in ethanol solution, after 10 minutes, record the mixed volume of ethanol and material (V 2 ), remove the material from...

Embodiment 2

[0026] Please refer to image 3 , a variable-diameter cylindrical three-layer artificial blood vessel, the inner diameter of the blood vessel is 4-7mm (the inner diameter is continuously and gradually changed), the length is 45cm, and the thickness of the tube wall is 577 microns. For the thickness, porosity and pore diameter test methods of each layer of the pipe body, refer to Example 1. The inner layer is a PU nanofiber layer with a thickness of 116 microns, a porosity of 75%, and an average pore diameter of 0.8 microns; the middle layer is a microporous polyurethane layer with a thickness of 252 microns, a porosity of 70%, and an average pore diameter of 26 microns ; The outer layer is warp-knitted polytetrafluoroethylene fibers with a thickness of 209 microns, a porosity of 45%, and an average pore size of 154 microns. Referring to Example 1, the water seepage performance of the artificial blood vessel was tested, and the water seepage measured at 16kPa was 0. Bending e...

Embodiment 3

[0028] Please refer to Figure 4 , a cylindrical three-branch three-layer structure artificial blood vessel, the inner diameter of the main body is 20 mm, the length is 40 cm, and the thickness of the tube wall is 535 microns. The thickness, porosity and pore diameter test methods of each layer of the main body and branches refer to Example 1. The inner layer of the main body is a PU nanofiber layer with a thickness of 147 microns, a porosity of 78%, and an average pore diameter of 1.1 microns; the middle layer is microporous silica gel with a thickness of 173 microns, a porosity of 63%, and an average pore diameter of 53 microns ; The outer layer is a fabric made of PET fibers through warp knitting, with a thickness of 215 microns, a porosity of 48%, and an average pore size of 164 microns. The internal diameter of the branches is 8 mm, the length is 15 cm, and the wall thickness of the tube is 443 microns. The inner layer of the branches is a PU nanofiber layer with a thic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com