Polyvinyl alcohol nanofiber emboliaztion agent as well as preparation method and application thereof

A nanofiber, polyvinyl alcohol technology, applied in the application, nanotechnology, nanotechnology and other directions, can solve problems such as drift, achieve the effect of reducing the number of times, reducing the economic burden, and reliable embolization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

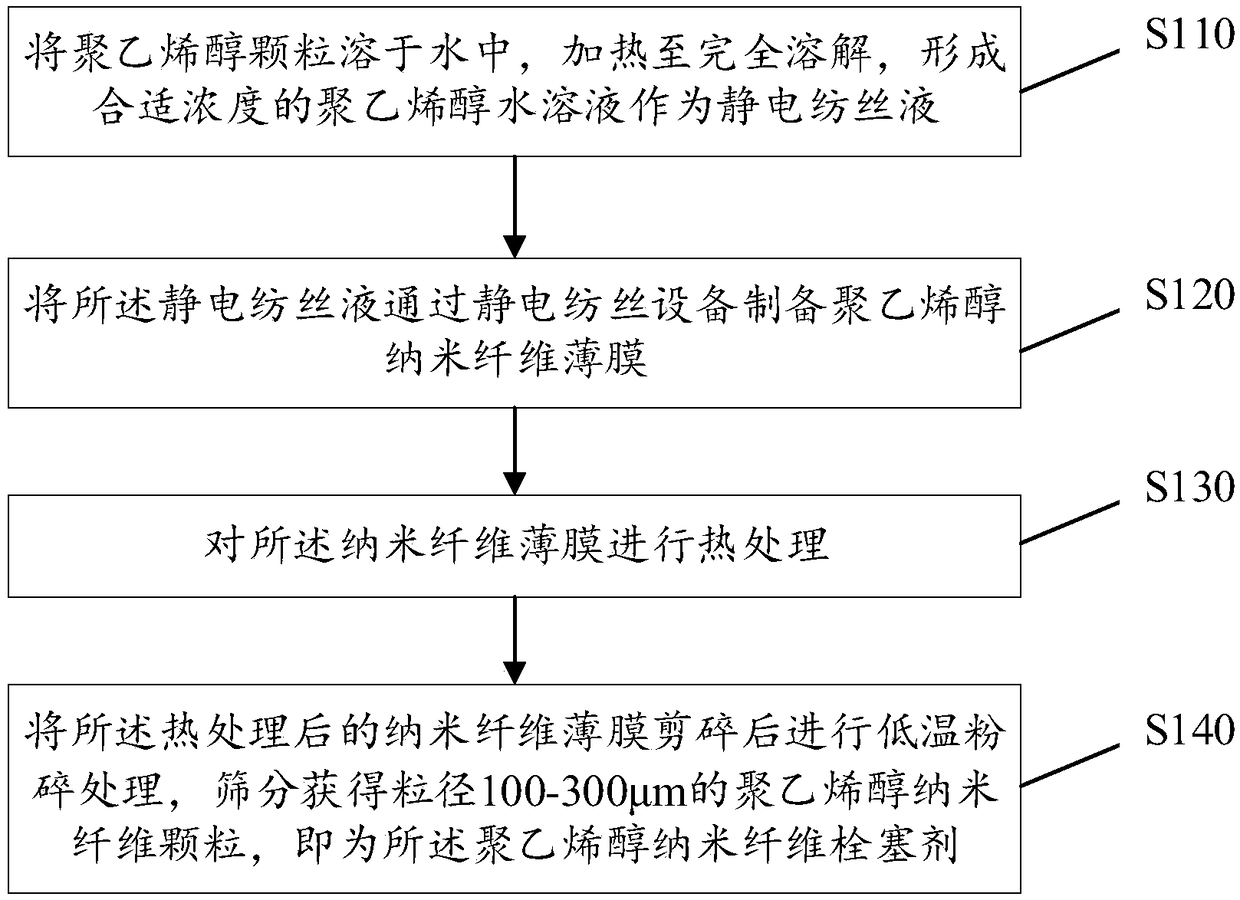

[0038] The embodiment of the present application also provides a preparation method of the above-mentioned polyvinyl alcohol nanofiber embolic agent, such as figure 1 As shown, it specifically includes the following steps:

[0039] Step S110: Dissolving the polyvinyl alcohol particles in water and heating until completely dissolved to form an aqueous solution of polyvinyl alcohol with a suitable concentration as an electrospinning solution;

[0040] In this step, when dissolving the polyvinyl alcohol, it can be heated in an oil bath / water bath under magnetic stirring until the PVA is completely dissolved, cooled and defoamed, and used as an electrospinning solution for later use.

[0041] Wherein, the concentration of the polyvinyl alcohol aqueous solution is 5%-10%, and the heating temperature is 85-95°C. Appropriate PVA concentration can ensure continuous nanofibers. If the concentration of PVA solution is too high, the viscosity of the system will be high, and the needle w...

Embodiment 1

[0057] A preparation method of PVA nanofiber embolic agent, comprises the steps:

[0058] S1: First measure 9.2ml of ultra-pure water and put it in a beaker, weigh 0.8g of PVA1799 powder and add it slowly, then mechanically stir and heat in an oil bath at 90°C for 1 hour to become transparent and viscous, cool and defoam for later use , configured as a spinning dope;

[0059] S2: Use a 20ml syringe equipped with a stainless steel needle to draw the spinning stock solution, use the needle as the positive pole, and the aluminum foil paper as the negative pole, set the receiving distance of the positive and negative poles to 15cm, the spinning voltage to 18KV, the propulsion rate to 0.9ml / h, and the temperature to 30°C , PVA nanofiber film was prepared by electrospinning;

[0060] S3: Carefully remove the PVA nanofiber film from the aluminum foil, and dry it in vacuum at 150°C for 15 minutes to obtain a PVA nanofiber film with good water resistance;

[0061] S4: The heat-treate...

Embodiment 2

[0069] A preparation method of PVA nanofiber embolic agent, comprises the steps:

[0070] S1: First measure 9.5ml of ultra-pure water and put it in a beaker, weigh 0.5g of PVA1799 powder and add it slowly, then mechanically stir and heat in an oil bath at 85°C for 1 hour to become transparent and viscous, cool and defoam for later use , configured as a spinning dope;

[0071] S2: Use a 20ml syringe equipped with a stainless steel needle to absorb the spinning stock solution, use the needle as the positive pole, and the aluminum foil paper as the negative pole, set the receiving distance of the positive and negative poles to 5cm, the spinning voltage to 16KV, the propulsion rate to 0.1ml / h, and the temperature to 30°C , PVA nanofiber film was prepared by electrospinning;

[0072] S3: Carefully remove the PVA nanofiber film from the aluminum foil, and dry it in vacuum at 100°C for 80 minutes to obtain a PVA nanofiber film with good water resistance;

[0073] S4: The heat-treat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com