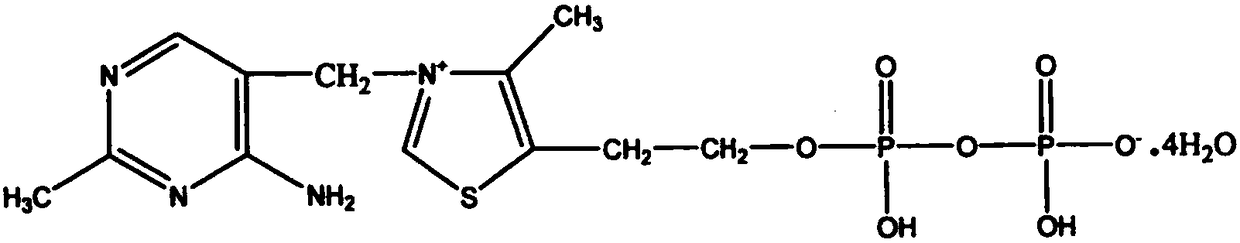

Preparation method of thiamine pyrophosphate tetrahydrate in 12 vitamin raw materials for injection

A technology of thiamine pyrophosphate tetrahydrate and thiamine pyrophosphate, which is applied in the field of preparation of 12 kinds of vitamin raw materials for injection, thiamine pyrophosphate tetrahydrate, can solve the problems of long production cycle, environmental pollution and the like, and achieves The effect of reducing production cost, reducing environmental pollution and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

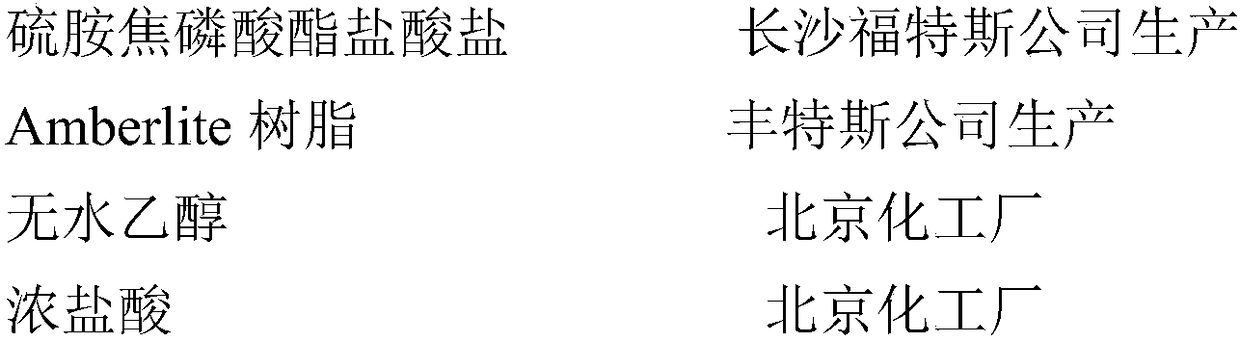

[0034] A preparation method of 12 kinds of vitamin raw materials thiamine pyrophosphate tetrahydrate for injection, characterized in that the preparation method comprises the following steps:

[0035] (1) Soak 2kg of Amberlite resin with 0.1mol / L HCl of 3.3L for 0.5h, filter, then repeatedly wash twice with 0.1mol / L HCl, filter, and dry to obtain acid-treated Amberlite resin;

[0036] (2) Soak the Amberlite resin that the acid treatment of step (1) gained is crossed 0.5h with 5% NaOH solution, filter, wash 2 times with 5% NaOH solution then, filter, wash the Amberlite resin that alkali treatment is crossed with distilled water, obtain Activated Amberlite resin; store the activated resin in a -4°C environment for future use.

[0037] (3) The activated 2kg Amberlite resin obtained in step (2) is placed in a container, then an appropriate amount of distilled water is added, vigorously stirred to drive out the air bubbles as much as possible, then the column packing takes by weigh...

Embodiment 2

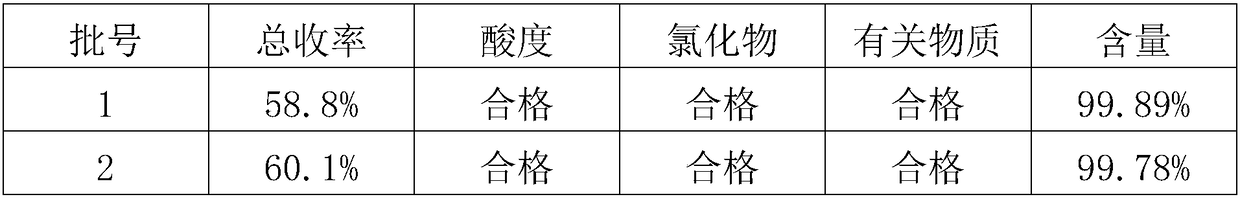

[0040] This embodiment relates to the quality detection of thiamine pyrophosphate tetrahydrate obtained in embodiment 1. The test results are shown in the table below:

[0041] Quality Test Data Sheet for Thiamine Pyrophosphate Tetrahydrate

[0042]

[0043]

[0044] It can be seen from the above table that the quality of thiamine pyrophosphate tetrahydrate prepared according to the method of the present application is qualified, and the yield and content are high.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com