Preparation method for low-temperature-resistant seed coating agent material

A technology of low temperature resistance and preparation steps is applied in the field of preparation of low temperature resistant seed coating materials, which can solve the problems of destroying the surface layer of plant cells, disorder of plant cell metabolism, poor low temperature resistance performance, etc., so as to reduce the damage and improve the phase transition temperature. , Improve the effect of low temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

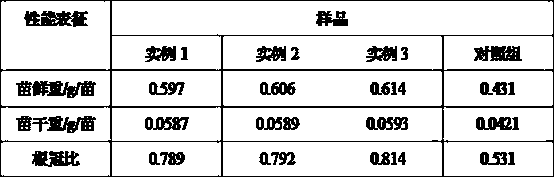

Examples

example 1

[0019] Take paraffin and heat to melt, collect molten paraffin and count parts by weight, weigh 45 parts of deionized water, 3 parts of Span-80 and 10 parts of molten paraffin respectively and place them in a high-speed shear emulsifier, at 1200r / min Cut down for 25 minutes, and adjust the pH to 4.0 with glacial acetic acid to obtain a dispersed emulsion. Then, in parts by weight, weigh 45 parts of ether, 6 parts of lecithin, 10 parts of dispersed emulsion and 10 parts of cholesterol in a Erlenmeyer flask. Heated in an oil bath at 125°C for 25 minutes, then stood to cool to room temperature, filtered and collected the filter cake, vacuum freeze-dried to obtain a dry filter cake and washed 3 times with a pH of 7.0 disodium hydrogen phosphate-sodium dihydrogen phosphate buffer solution to obtain a modified granules; by weight, weigh 45 parts of xanthan gum, 3 parts of peach gum, 6 parts of lecithin, 3 parts of sodium dodecylsulfonate and 10 parts of modified particles in a mixer,...

example 2

[0021] Take the paraffin and heat to melt, collect the molten paraffin and count by weight parts, weigh 47 parts of deionized water, 4 parts of Span-80 and 12 parts of molten paraffin respectively and place them in a high-speed shear emulsifier, at 1450r / min Cut down for 27 minutes, and adjust the pH to 4.0 with glacial acetic acid to obtain a dispersed emulsion. Then, in parts by weight, weigh 47 parts of ether, 7 parts of lecithin, 12 parts of dispersed emulsion and 12 parts of cholesterol in a Erlenmeyer flask. Heated in an oil bath at 145°C for 27 minutes, then stood to cool to room temperature, filtered and collected the filter cake, vacuum freeze-dried to obtain a dry filter cake and washed 4 times with a pH of 7.0 disodium hydrogen phosphate-sodium dihydrogen phosphate buffer solution to obtain a modified 4 parts of xanthan gum, 4 parts of peach gum, 7 parts of lecithin, 4 parts of sodium dodecylsulfonate and 15 parts of modified granules were weighed in parts by weight ...

example 3

[0023] Take paraffin and heat to melt, collect molten paraffin and count parts by weight, weigh 50 parts of deionized water, 5 parts of Span-80 and 15 parts of molten paraffin respectively and place them in a high-speed shear emulsifier, at 1500r / min Cut down for 30 minutes, and adjust the pH to 4.0 with glacial acetic acid to obtain a dispersed emulsion. Then, in parts by weight, weigh 50 parts of ether, 8 parts of lecithin, 15 parts of dispersed emulsion and 15 parts of cholesterol in a Erlenmeyer flask. Heated in an oil bath at 160°C for 30 minutes, then stood to cool to room temperature, filtered and collected the filter cake, vacuum freeze-dried to obtain a dry filter cake and washed 5 times with a pH of 7.0 disodium hydrogen phosphate-sodium dihydrogen phosphate buffer solution to obtain a modified Parts by weight, respectively weigh 50 parts of xanthan gum, 5 parts of peach gum, 8 parts of lecithin, 5 parts of sodium dodecylsulfonate and 18 parts of modified particles in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com