Intelligent control charging device of horizontal and continuous charging electric arc furnace and using method

A feeding device and intelligent control technology, applied in the field of arc smelting, can solve the problems of inability to accurately control the amount of materials added, inability to add raw materials to electric furnaces, and no weighing device, etc., to achieve high economic and practical value, improve labor environment, and reduce labor. the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

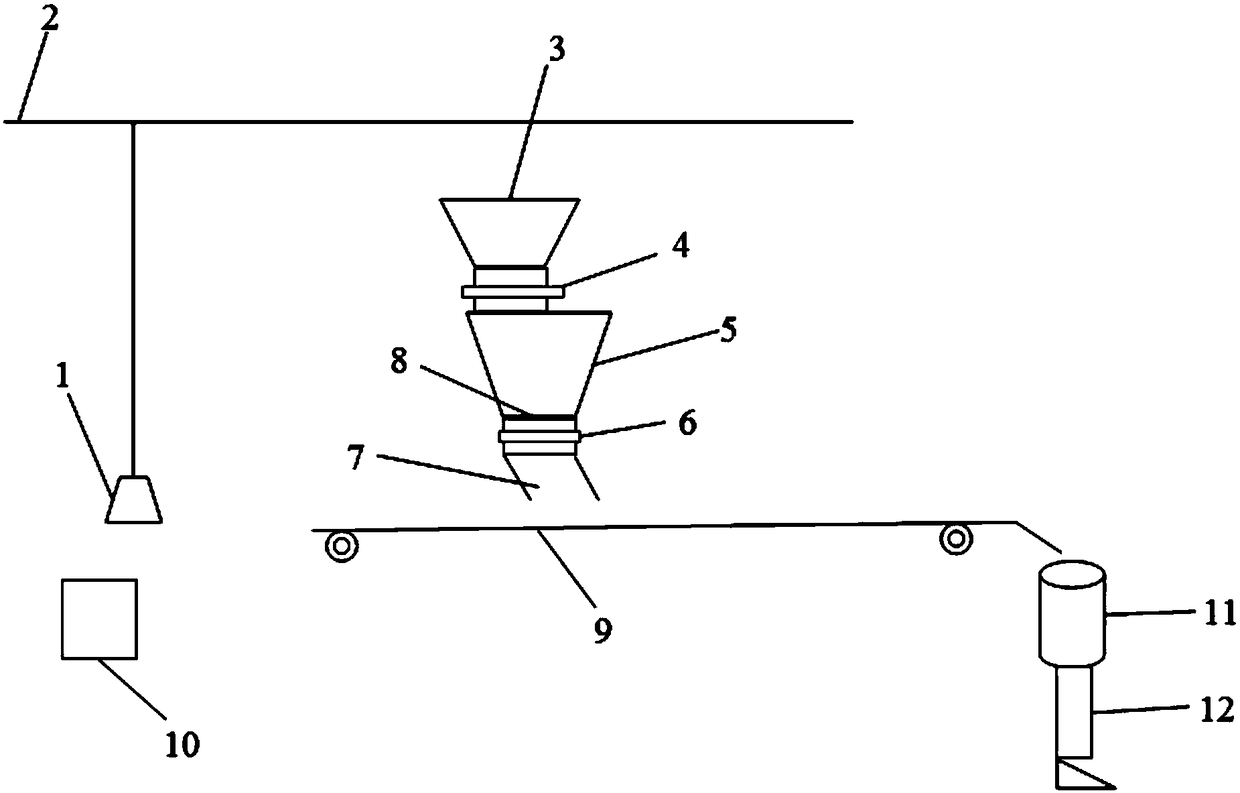

[0042] An intelligent control feeding device for a horizontal continuous feeding electric furnace, including: raw material feeding device, high-level silo equipment, belt conveyor, mixer, material distributing machine and control system; the raw material feeding device is controlled by the control system to transport raw materials to the high-level In the silo equipment, the high-level silo equipment unloads the raw materials according to the required amount of raw materials. The belt conveyor is set under the high-level silo equipment. The feeding port of the high-level silo equipment corresponds to the conveyor belt of the belt conveyor. The output end of the conveyor corresponds to the setting of the material inlet of the mixer, and the output port of the mixer corresponds to the setting of the feeding port of the distributing machine. The raw materials put in from the high-level silo equipment are transported to the mixing device through the belt conveyor. After the materia...

Embodiment 2

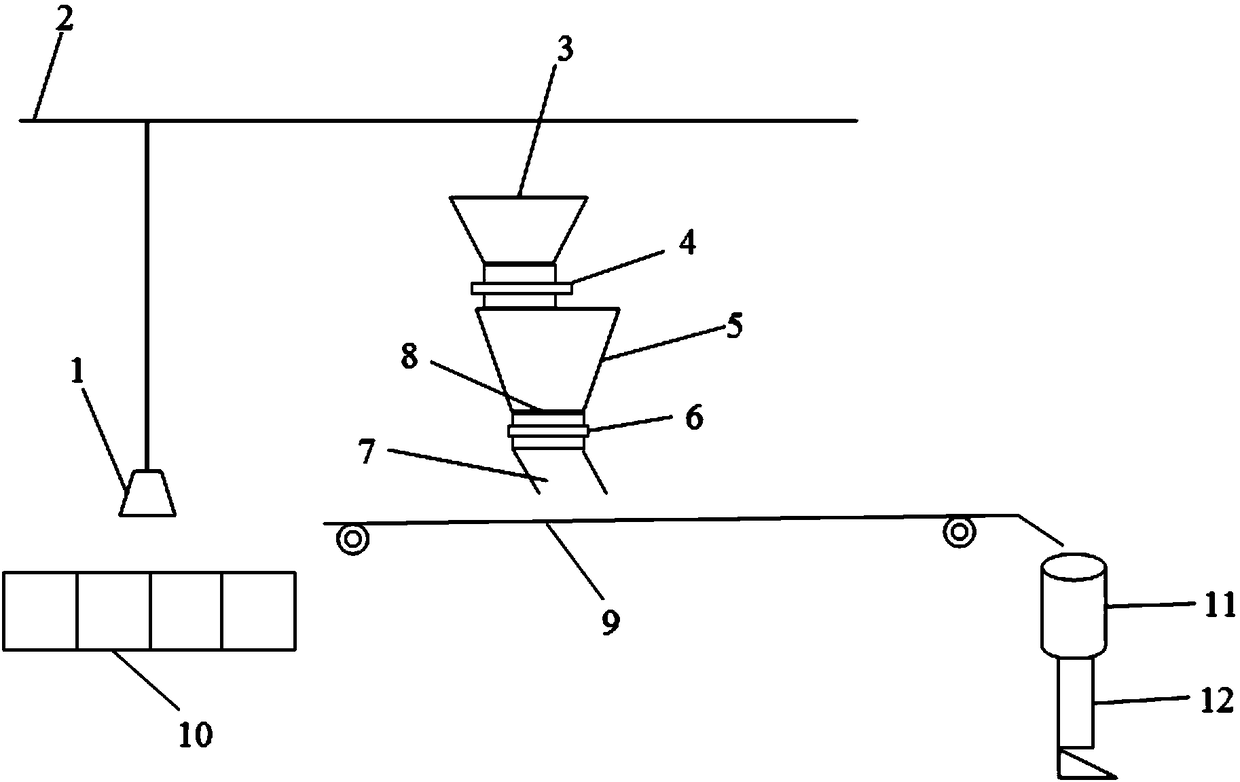

[0054] In order to speed up the feeding speed and further improve the work efficiency, this embodiment is based on the example 1, and the floor material bins are set to be multiple, correspondingly provided with a plurality of high-level material bins, each of which is equipped with The feed gate and all feed valves are set corresponding to the weighing hopper to ensure that the material can fall into the weighing hopper after falling from the feed valve. The control system is set for a floor material bin corresponding to a high-level bin, and the materials should be prepared in advance , corresponding to the control system settings, the corresponding programs are placed in the designated corresponding floor material bins, to ensure that the materials match the control system’s batching model settings, and to ensure the precise control of the amount of all materials and the materials used.

[0055] In order to ensure that the materials in the high-level silos can meet the mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com