Manufacturing method capable of improving plane VDMOS gate-oxide breakdown

A manufacturing method and planar technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problem of gate oxide breakdown reduction and achieve simple results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

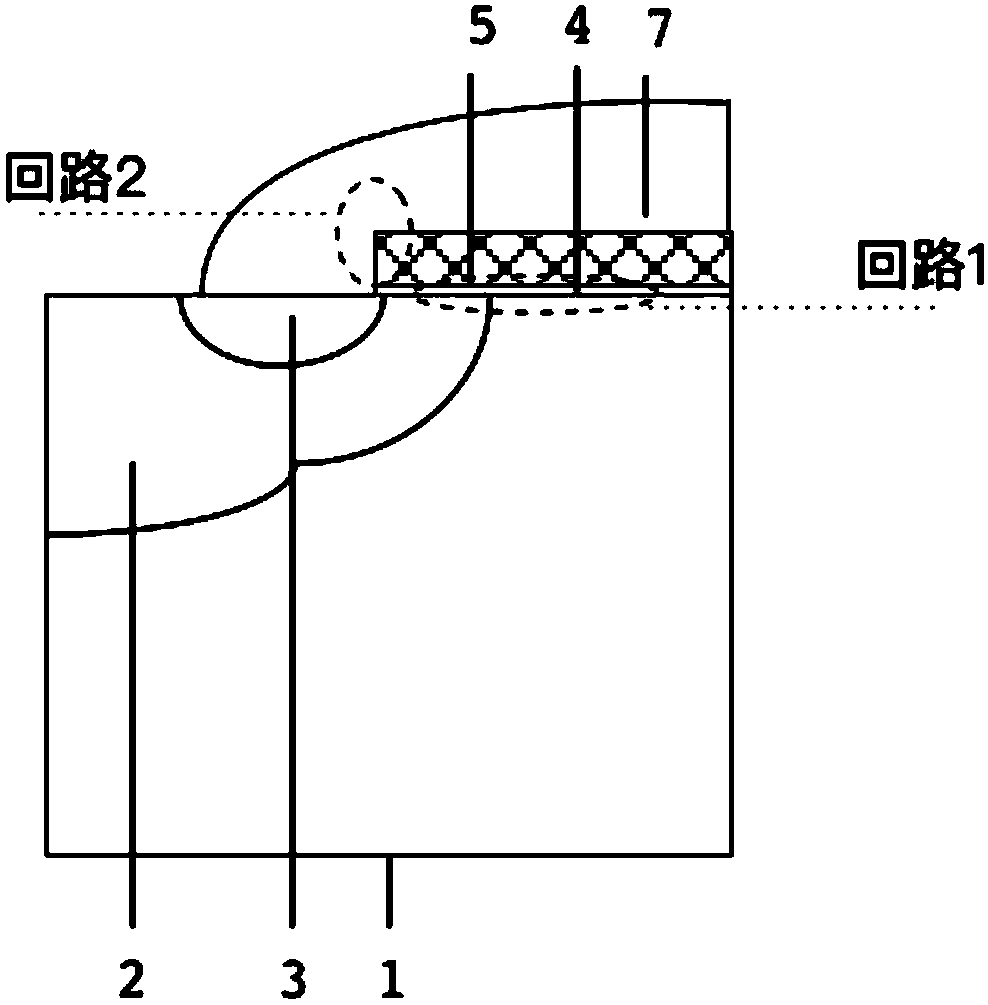

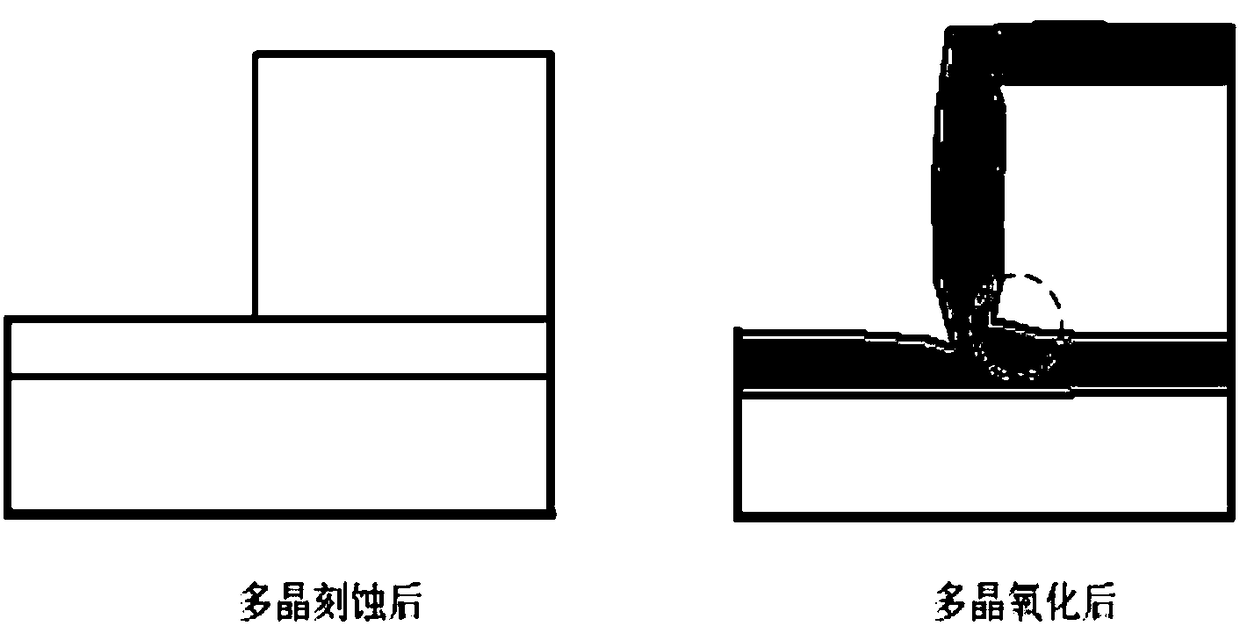

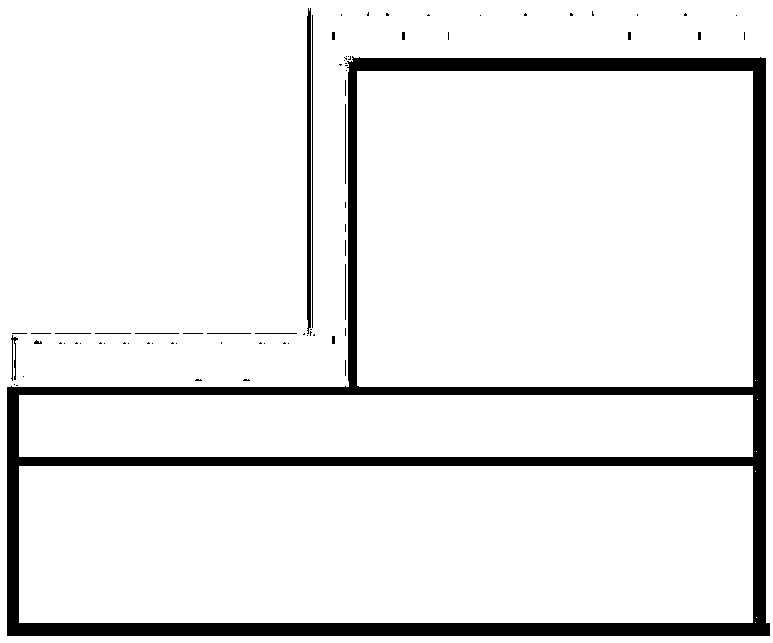

[0038] A manufacturing method for improving planar VDMOS gate oxide breakdown, characterized in that it includes an epitaxial layer 1, a well region 2, a source region 3, a gate oxide layer 4, a polycrystalline layer 5, a polycrystalline conformal dielectric layer 6, and a dielectric layer 7 and metal layer 8.

[0039] Do the following steps:

[0040] 1) The epitaxial layer 1 is formed using a conventional method.

[0041] 2) Prepare well region 2 and source region 3 .

[0042] The well region 2 is located in the epitaxial layer 1 , and the upper surface of the well region 2 is coplanar with the upper surface of the epitaxial layer 1 . The source region 3 is located in the well region 2 , and the upper surface of the well region 2 is coplanar with the upper surface of the epitaxial layer 1 .

[0043] 3) Depositing the gate oxide layer 4 .

[0044] The gate oxide layer 4 covers the upper surface of the epitaxial layer 1 . The gate oxide layer 4 also covers part of the surf...

Embodiment 2

[0057] A manufacturing method for improving planar VDMOS gate oxide breakdown, characterized in that it includes an epitaxial layer 1, a well region 2, a source region 3, a gate oxide layer 4, a polycrystalline layer 5, a polycrystalline conformal dielectric layer 6, and a dielectric layer 7 and metal layer 8.

[0058] Do the following steps:

[0059] 1) The epitaxial layer 1 is formed using a conventional method.

[0060] 2) Prepare well region 2 and source region 3 .

[0061] The well region 2 is located in the epitaxial layer 1 , and the upper surface of the well region 2 is coplanar with the upper surface of the epitaxial layer 1 . The source region 3 is located in the well region 2 , and the upper surface of the well region 2 is coplanar with the upper surface of the epitaxial layer 1 .

[0062] 3) Depositing the gate oxide layer 4 .

[0063] The gate oxide layer 4 covers the upper surface of the epitaxial layer 1 . The gate oxide layer 4 also covers part of the surf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com