Preparation method for adsorbing material for lysine

An adsorption material and lysine technology, applied in the field of adsorbent preparation, can solve the problems of complicated operation, long consumption time, etc., and achieve the effects of large adsorption capacity, firm adhesion, and not easy to be broken.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

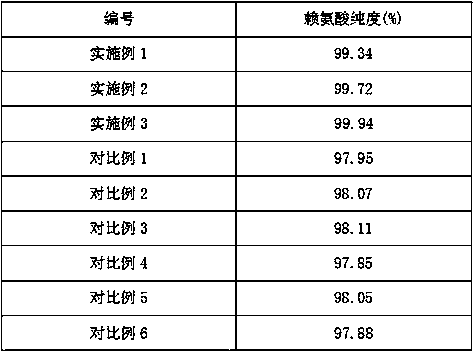

Examples

Embodiment 1

[0030] Step 1. Prepare the enhanced adsorption composition, each representing a 1Kg quality, which consists of:

[0031] Component Parts by weight

[0032] Component Parts by weight

[0033] White oil 100 parts

[0034] 3 parts styrene

[0035] Methylcyclohexene-1,2-dicarboxylic anhydride 0.5 parts

[0036] 1-amino-3-buten-2-ol 2 parts

[0037] 2-Hydroxyethyl methacrylate phosphate 0.3 parts

[0038] 0.3 parts of methacryloyloxyethyl trimellitic anhydride

[0039] Propylene hexafluoroisopropyl ether 0.007 part

[0040] Bis(trimethylenedithio)tetrathiafulvalene 0.0003 parts

[0041] Step 2. prepare the adsorption material for lysine, each part represents 1Kg quality, and it consists of:

[0042] Component Parts by weight

[0043] Porous glass microspheres 100 parts

[0044] Enhanced adsorption composition 20 parts

[0045] 1 part polyvinyl alcohol

[0046] Ammonium persulfate 0.75 parts

[0047] 600 parts of water

[0048] Mix the above components evenly, raise th...

Embodiment 2

[0050] Step 1. Prepare the enhanced adsorption composition, each representing a 1Kg quality, which consists of:

[0051] Component Parts by weight

[0052] Component Parts by weight

[0053] White oil 100 parts

[0054] 1 part styrene

[0055] 0.2 parts of methylcyclohexene-1,2-dicarboxylic anhydride

[0056] 1 part of 1-amino-3-buten-2-ol

[0057] 2-Hydroxyethyl methacrylate phosphate 0.1 parts

[0058] Methacryloyloxyethyl trimellitic anhydride 0.1 parts

[0059] Propylene hexafluoroisopropyl ether 0.005 parts

[0060] Bis(trimethylenedithio)tetrathiafulvalene 0.0001 parts

[0061] Step 2. prepare the adsorption material for lysine, each part represents 1Kg quality, and it consists of:

[0062] Component Parts by weight

[0063] Porous glass microspheres 100 parts

[0064] Enhanced adsorption composition 10 parts

[0065] 0.5 parts of polyvinyl alcohol

[0066] Ammonium persulfate 0.5 parts

[0067] 400 parts of water

[0068] Mix the above components evenly, r...

Embodiment 3

[0070] Step 1. Prepare the enhanced adsorption composition, each representing a 1Kg quality, which consists of:

[0071] Component Parts by weight

[0072] White oil 100 parts

[0073] Styrene 5 parts

[0074] 0.6 parts of methylcyclohexene-1,2-dicarboxylic anhydride

[0075] 1-amino-3-buten-2-ol 6 parts

[0076] 2-Hydroxyethyl methacrylate phosphate 0.5 parts

[0077] 0.5 parts of methacryloyloxyethyl trimellitic anhydride

[0078] 0.05 parts of propenyl hexafluoroisopropyl ether

[0079] Bis(trimethylenedithio)tetrathiafulvalene 0.001 parts

[0080] Step 2. prepare the adsorption material for lysine, each part represents 1Kg quality, and it consists of:

[0081] Component Parts by weight

[0082] Porous glass microspheres 100 parts

[0083] Enhanced adsorption composition 30 parts

[0084] 1.5 parts of polyvinyl alcohol

[0085] 1 part ammonium persulfate

[0086] 800 parts of water

[0087] Mix the above components evenly, raise the temperature to 105°C, and reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com