Ultrasonic vibrating aided welding test device

A technology for auxiliary welding and testing equipment, applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems of unfixed impact time and distance, strict requirements on the shape of the welded parts, and difficulty in accurately controlling energy, etc. , to achieve the effect of reducing welding defects, uniform grain size, and accelerating escape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

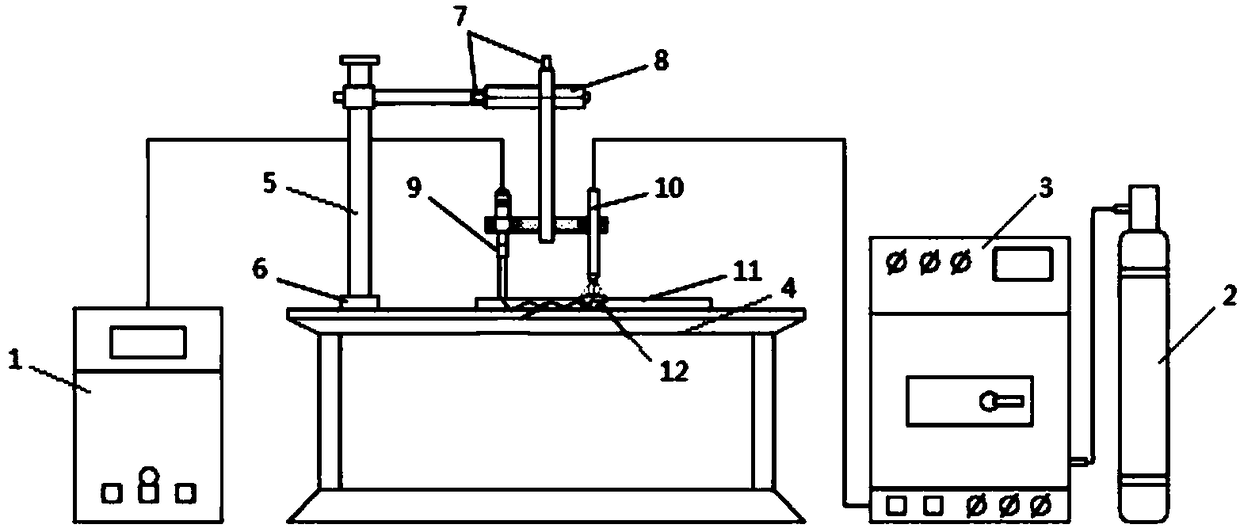

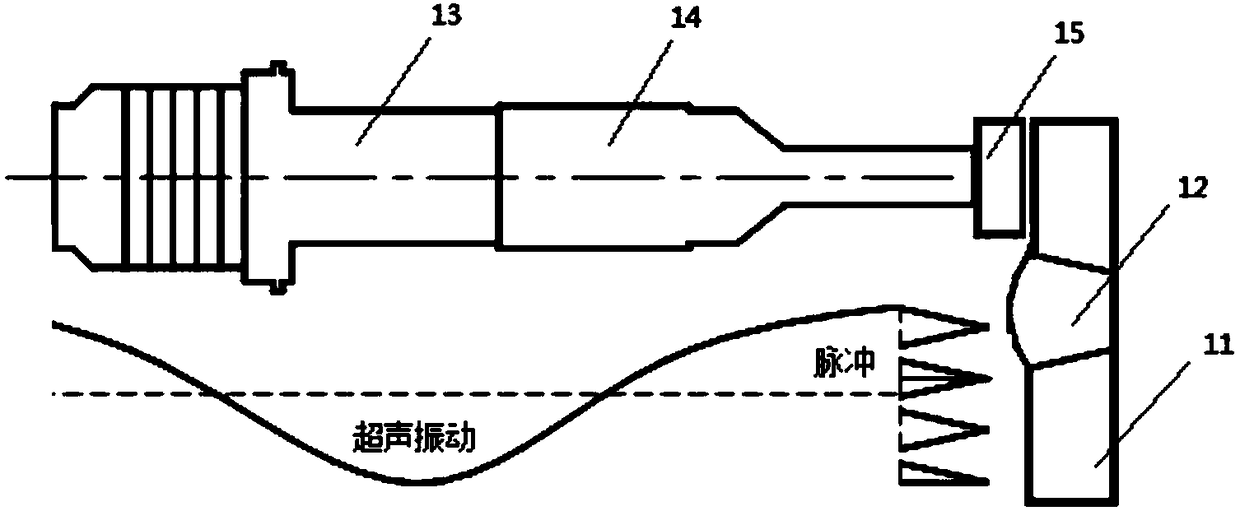

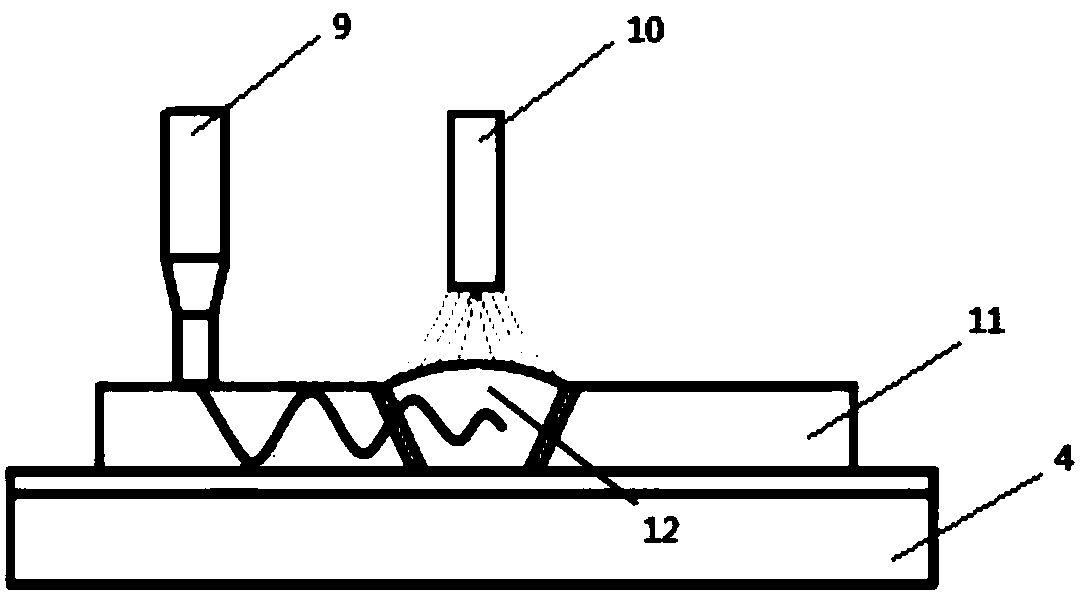

[0021] Example: such as Figure 1-3 As shown, the present invention provides a kind of ultrasonic vibration assisted welding test device, comprises sonotrode 1, gas cylinder 2, welding power source 3 and the transducer 13 that is connected with sonotrode 1; 4. The workpiece 11 on the surface, the ultrasonic generator 1 and the welding power supply 3 are respectively connected with a vibrating gun 9 and a welding torch 10, the welding torch 10 is located above the molten pool 12 on the surface of the workpiece 11, and the vibrating gun 9 and the welding torch 10 are fixed by connecting rods On the ball screw 8, the vibrating gun 9 and the welding torch 10 are hoisted side by side on the upper end of the workpiece 11; the vibrating gun 9 includes a transducer 13, a horn 14 and a vibrating head 15; the ultrasonic generator 1 is connected to the transducer 13, One end of the transducer 13 is connected to the horn 14 , and the other end of the horn 14 is installed with a vibrating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com