Energy-saving heat insulation material applied to buildings and preparation method thereof

A thermal insulation material and building energy-saving technology, applied in the field of building materials, can solve the problems of inconspicuous thermal insulation effect, poor impact resistance, and difficult construction, and achieve remarkable thermal insulation and energy-saving effects, poor impact resistance, and improved The effect of thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

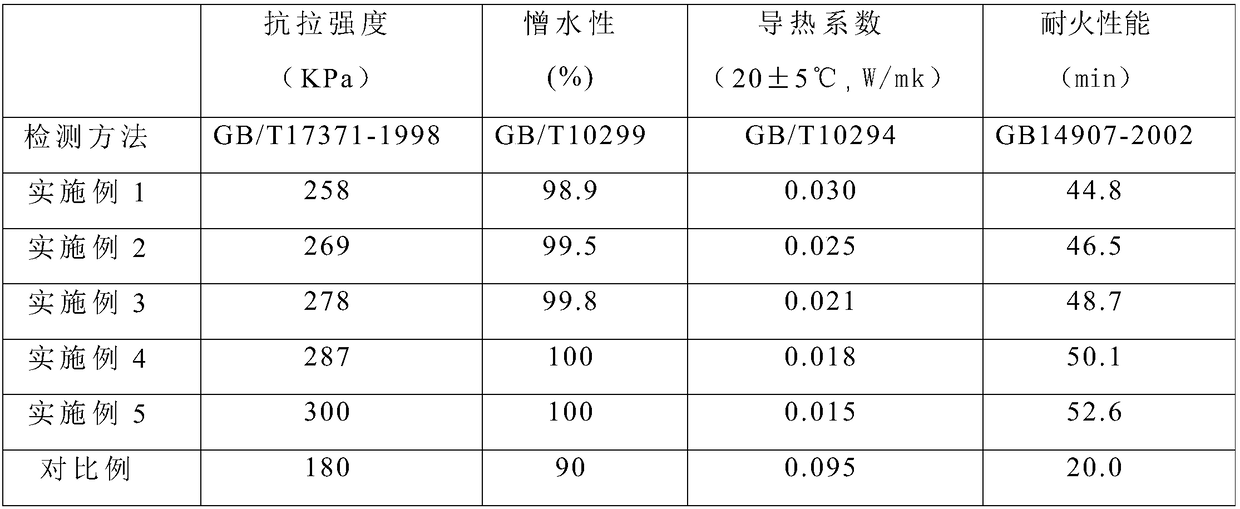

Examples

Embodiment 1

[0029] A building energy-saving thermal insulation material, comprising the following raw materials in parts by weight: 45 parts of waste coal slag, 5 parts of graphene sponge, 20 parts of magnesium aluminum spinel, 5 parts of hollow glass microspheres, 10 parts of asbestos-free mineral fiber, abaca 10 parts of fiber, 5 parts of cryptane ion salt fireproof and heat preservation functional auxiliary, 2 parts of silane coupling agent KH-550.

[0030] The preparation method of the described cryptane ion salt fireproof and thermal insulation functional auxiliary agent comprises the following steps:

[0031] 1) Add 18 g of cryptane into 100 g of acetonitrile, stir at 80° C., add 10 g of epichlorohydrin after it is completely dissolved, keep stirring for 5 hours, and then remove the solvent with a rotary evaporator to obtain a crude product;

[0032] 2) Dissolve 10 g of the crude product prepared in step 1) in 100 g of dimethyl sulfoxide, add 30 g of amino resin and 0.3 g of azodica...

Embodiment 2

[0036] A building energy-saving thermal insulation material, comprising the following raw materials in parts by weight: 47 parts of waste coal slag, 7 parts of graphene sponge, 23 parts of magnesium aluminum spinel, 7 parts of hollow glass microspheres, 13 parts of asbestos-free mineral fiber, abaca 13 parts of fiber, 7 parts of cryptane ion salt fireproof and heat preservation functional auxiliary, 3 parts of silane coupling agent KH-560.

[0037] The preparation method of the described cryptane ion salt fireproof and thermal insulation functional auxiliary agent comprises the following steps:

[0038] 1) Add 18 g of cryptane into 120 g of diethyl ether, stir at 83° C., add 35 g of epichlorohydrin after it is completely dissolved, keep stirring for 5.5 hours, and then remove the solvent with a rotary evaporator to obtain a crude product;

[0039] 2) Dissolve 13g of the crude product prepared in step 1) in 120g of N,N-dimethylformamide, add 35g of amino resin and 0.35g of wate...

Embodiment 3

[0043] A building energy-saving thermal insulation material, comprising the following raw materials in parts by weight: 50 parts of waste coal slag, 8 parts of graphene sponge, 27 parts of magnesium aluminum spinel, 8 parts of hollow glass microspheres, 17 parts of asbestos-free mineral fiber, abaca 17 parts of fiber, 8 parts of cryptane ion salt fireproof and heat preservation functional additive, 4 parts of silane coupling agent KH-570.

[0044] The preparation method of the described cryptane ion salt fireproof and thermal insulation functional auxiliary agent comprises the following steps:

[0045] 1) Add 18g of cryptane into 130g of ethyl acetate, stir at 86°C, add 10g of epichlorohydrin after it is completely dissolved, keep stirring for 6 hours, and then remove the solvent with a rotary evaporator to obtain a crude product ;

[0046] 2) Dissolve 17g of the crude product prepared in step 1) in 130g of N-methylpyrrolidone, add 40g of amino resin and 0.4g of azobisisobuty...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com