Low-temperature co-fired ceramic material with low dielectric constant and low loss and preparation method thereof

A technology of low-temperature co-fired ceramics and low dielectric constant, applied in the field of low-temperature co-fired ceramics, can solve the problems of deterioration of material properties and process applicability, difficult to scale up production, difficult to grind and fine processing, etc. agent, beneficial to industrial production, and the effect of excellent insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The invention provides a method for preparing a low-dielectric constant and low-loss low-temperature co-fired ceramic material, comprising:

[0041] Step 1. Weigh 10-40 parts by mass of Al 2 o 3 , 0 to 40 parts by mass of SiO 2 , 0-60 parts by mass of powder A, 0-60 parts by mass of powder B, 8-30 parts by mass of powder C and 0-0.5 parts by mass of toner, the toner is Co 3 o 4 , MnO 2 、Cr 2 o 3 and SrCO 3 One or more of them, the coloring material can be added or not according to the needs, put the prepared powder into the ball mill for mixing, the ball / material mass ratio is 2-10, and the grinding ball is zirconia ball , the ball milling time is 4 to 8 hours, the speed is 250 to 450 rpm, the powder after ball milling is put into an oven and dried at 120°C, and the powder is ground and passed through a 100-mesh sieve;

[0042] Step 2, take 2 grams of the above powder, add 15-20 drops of PVA aqueous solution (6.5wt% polyvinyl alcohol) to bond and granulate, and ...

Embodiment

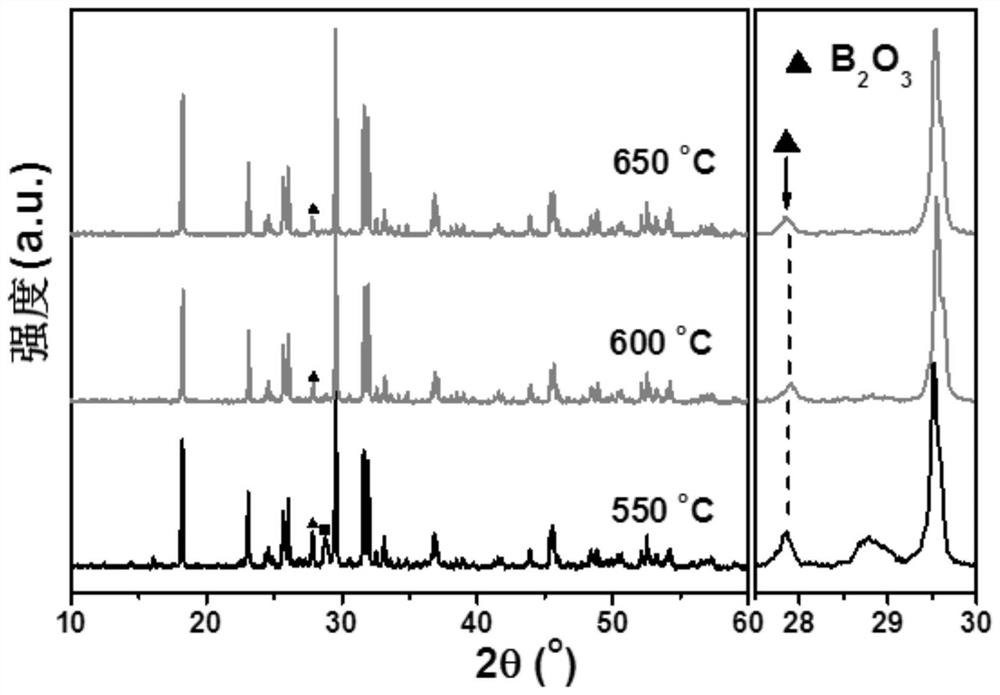

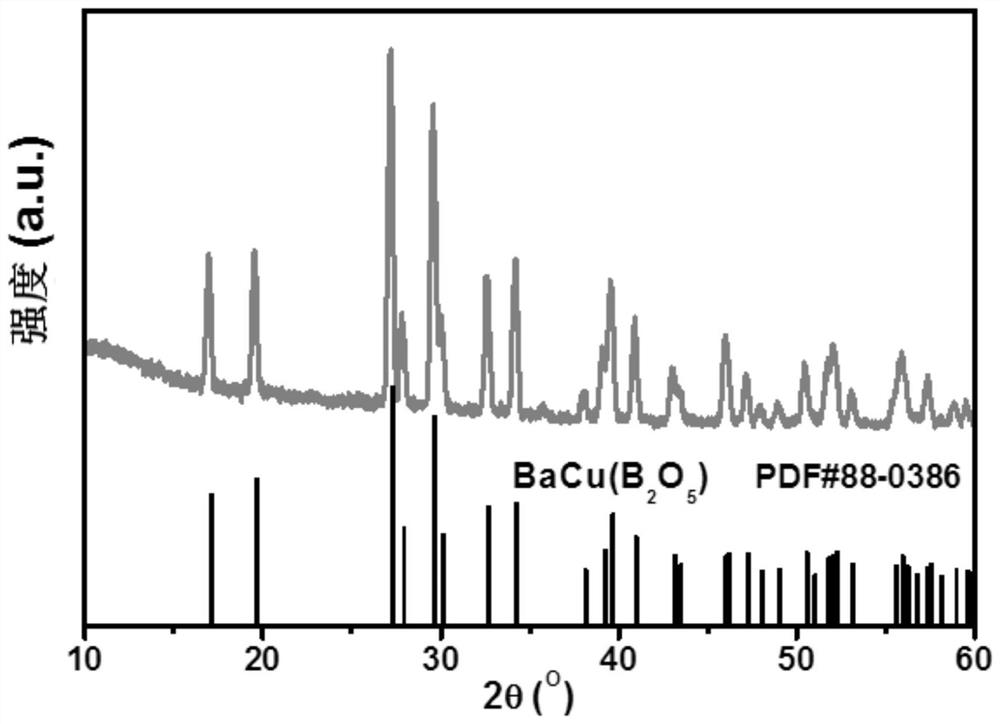

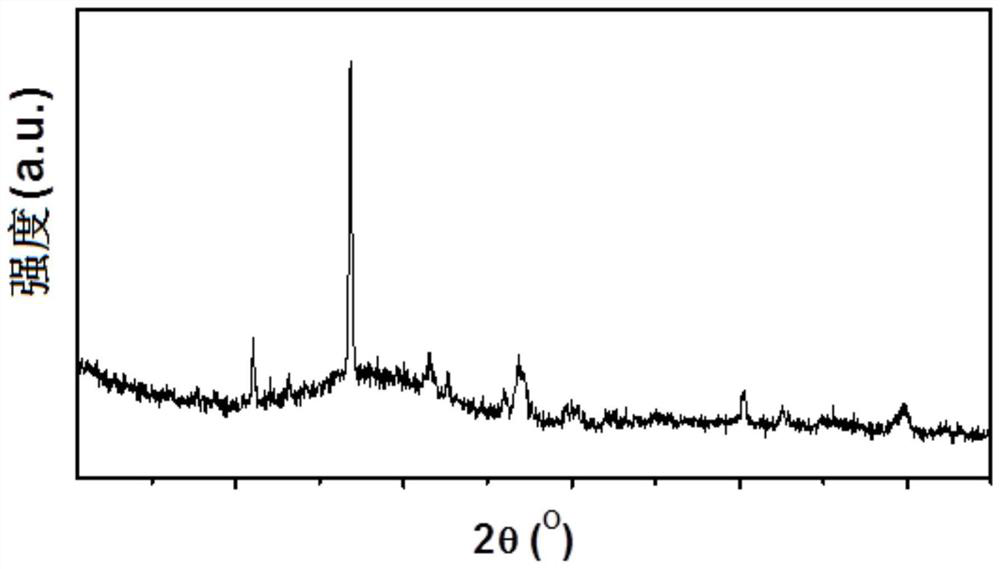

[0054] The present invention calculates the formula according to the number of parts by mass, and specific examples are shown in Table 1. Use analytically pure Al 2 o 3 , SiO 2 and solid-phase synthesized powders A, B and C, where Al 2 o 3 The mass parts are 10-40, SiO 2 The mass parts of powder A are 0-40, the powder A is calcined body, its mass parts are 0-60, and the components of powder A are 40-70 mass parts of Bi 2 o 3 , 10-30 parts by mass of ZnO, 15-45 parts by mass of H 3 BO 3 ; When in use, it can be in Bi 2 o 3 , ZnO, H 3 BO 3 Prepare powder A within the mass range, the preferred component of powder A in table 1 is the Bi of 60 mass parts 2 o 3 , 20 parts by mass of ZnO, 20 parts by mass of H 3 BO 3 , Bi of other components 2 o 3 , ZnO, H 3 BO 3 All can meet the requirements, so I will not elaborate here; powder B is a calcined body, its mass part is 0-60, and its components are BaO precursor, CuO and H in a molar ratio of 1:1:2. 3 BO 3 ; Powder...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com