Polyester type glazing-free yellow primer powder and preparation method thereof

A polyester type, bright yellow technology, applied in powder coatings, anti-corrosion coatings, coatings, etc., can solve the problems of poor impact resistance, poor weather resistance, easy to change color, etc., to ensure stability and service life, and improve products Quality, high adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

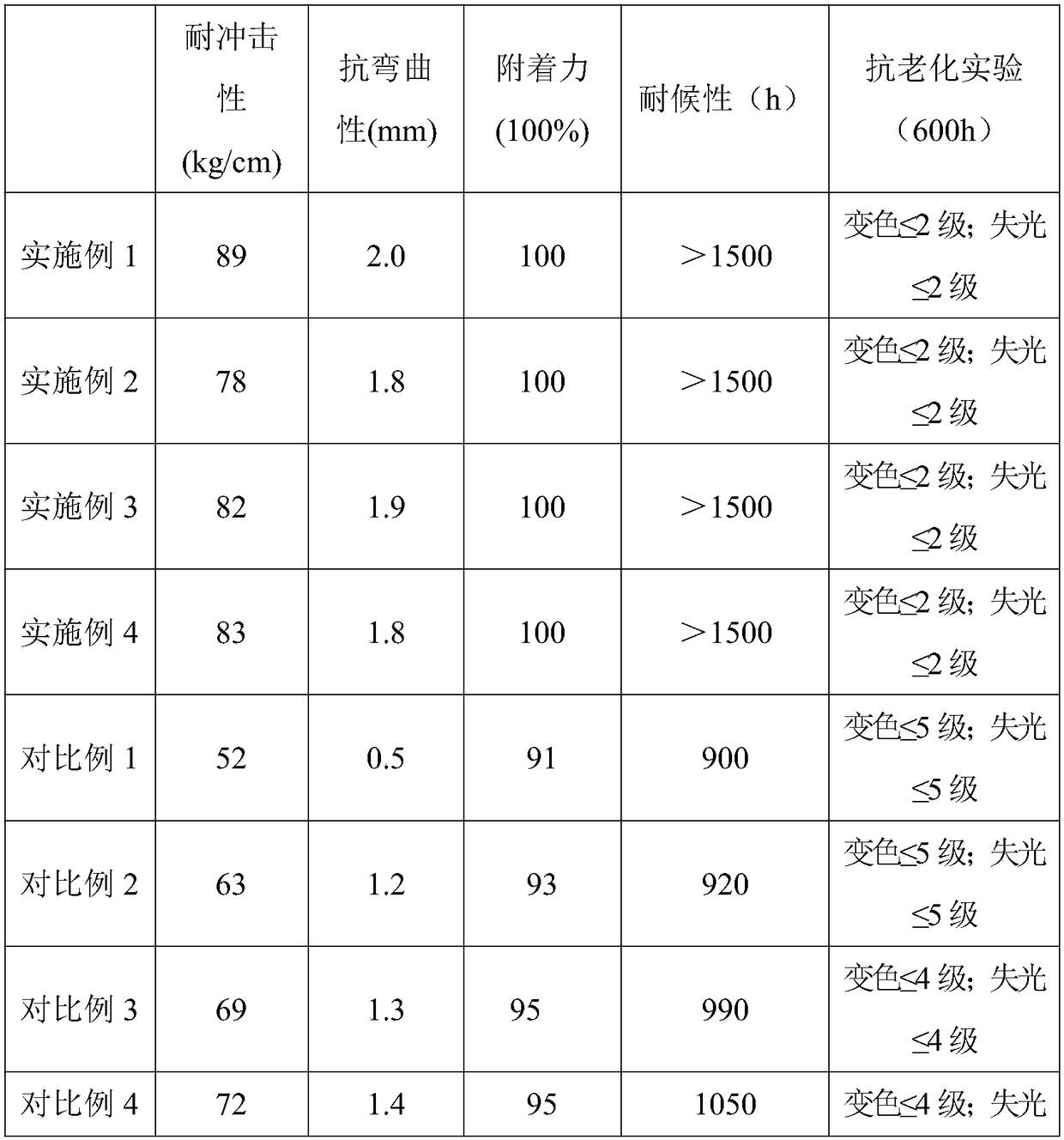

Examples

Embodiment 1

[0021] Polyester-type varnish-free yellow base powder, in parts by weight, includes the following raw materials: 25 parts of modified acrylic acid, 2 parts of electrification agent, 3 parts of mixed pigment, 1 part of degassing agent, 0.3 part of dispersant, toughening agent 0.7 parts of brightening agent, 0.35 parts of brightening agent, 0.15 parts of wetting agent, 0.2 parts of preservative, 0.2 parts of antioxidant, 0.15 parts of light stabilizer. Fatty acid, the dispersant is zinc sulfur, the toughening agent is pvc toughening agent, the wetting agent is heptadecyl imidazoline, and the preservative is 5-chloro-2-methyl-4-isothiazoline- 3-ketone, the antioxidant is a phosphite, and the light stabilizer is a hindered amine light stabilizer.

[0022] The modified acrylic compound includes the following raw materials in parts by weight: 0.8 parts of PE wax powder, 3.5 parts of methacrylic acid, 16 parts of polybutylene terephthalate, 1.9 parts of 6-pentanediol, cis 2 parts of...

Embodiment 2

[0031] Polyester-type varnish-free yellow base powder, in parts by weight, includes the following raw materials: 20 parts of modified acrylic acid, 1 part of electrification agent, 2 parts of mixed pigment, 0.5 part of degassing agent, 0.2 part of dispersant, toughening agent 0.5 parts of brightening agent, 0.2 parts of brightening agent, 0.1 part of wetting agent, 0.1 part of preservative, 0.1 part of antioxidant, 0.1 part of light stabilizer, the charging agent is β-hydroxyalkylamide, the degassing agent is hard Fatty acid, the dispersant is zinc sulfur, the toughening agent is pvc toughening agent, the wetting agent is heptadecyl imidazoline, and the preservative is 5-chloro-2-methyl-4-isothiazoline- 3-ketone, the antioxidant is a phosphite, and the light stabilizer is a hindered amine light stabilizer.

[0032] The modified acrylic compound, in parts by weight, includes the following raw materials: 0.5 parts of PE wax powder, 3 parts of methacrylic acid, 14 parts of polybu...

Embodiment 3

[0041]Polyester-type varnish-free yellow base powder, in parts by weight, includes the following raw materials: 20-30 parts of modified acrylic acid, 3 parts of charging agent, 5 parts of mixed pigment, 0.2 part of degassing agent, 0.5 part of dispersing agent, 1 part of toughening agent, 0.5 part of brightening agent, 0.3 part of wetting agent, 0.3 part of preservative, 0.3 part of antioxidant, 0.3 part of light stabilizer, described electrification agent is β-hydroxyalkylamide, degassing agent It is stearic acid, the dispersant is sulfur zinc, the toughening agent is pvc toughening agent, the wetting agent is heptadecyl imidazoline, and the preservative is 5-chloro-2-methyl-4 isothiazole Lin-3-one, the antioxidant is a phosphite, and the light stabilizer is a hindered amine light stabilizer.

[0042] The modified acrylic compound includes the following raw materials in parts by weight: 1 part of PE wax powder, 4 parts of methacrylic acid, 19 parts of polybutylene terephthala...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Impact resistance | aaaaa | aaaaa |

| Bending resistance | aaaaa | aaaaa |

| Impact resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com