A kind of micro-alloy steel thick plate and normalizing rolling method thereof

A technology of normalizing rolling and micro-alloy steel, which is applied in the field of steel production. It can solve the problems of high conventional process, cumbersome, uneven performance of normalized extra-thick steel plates, etc., achieve a wide process window, solve uneven performance, and improve product performance. The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

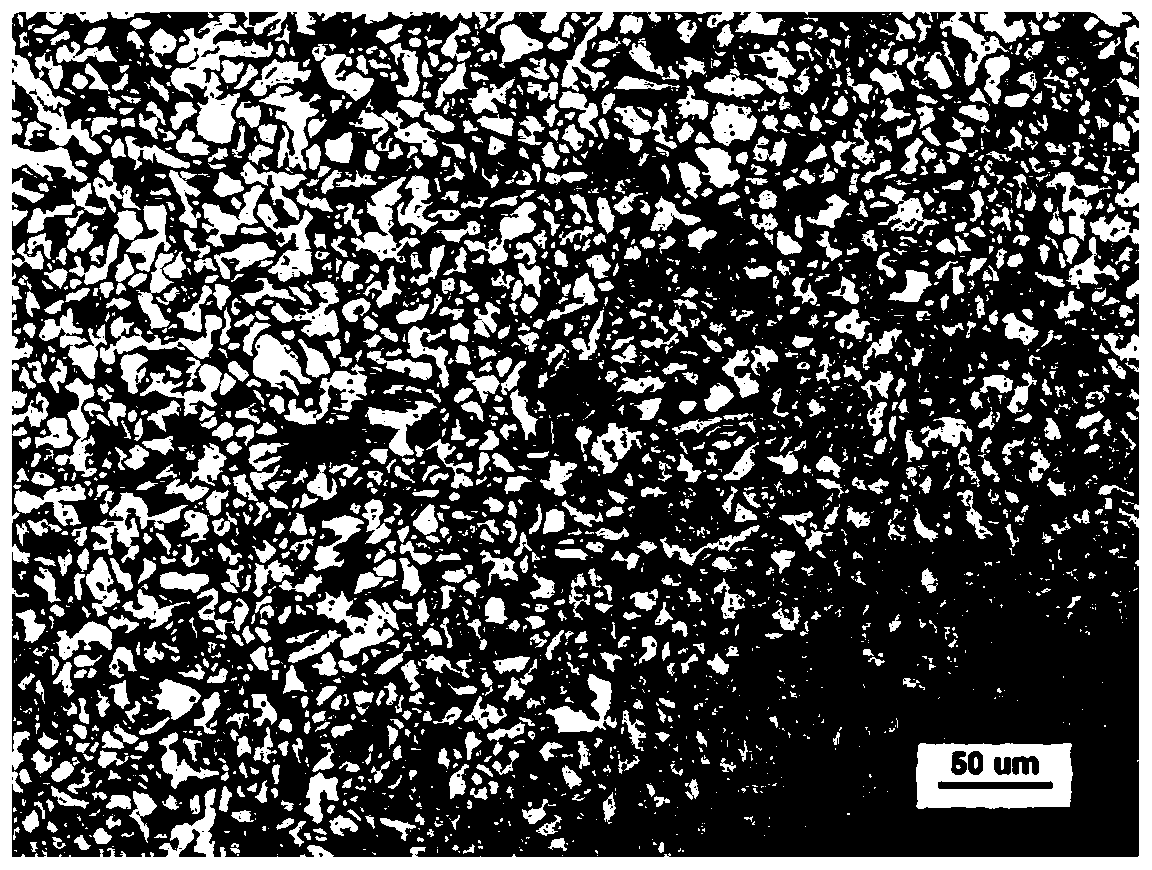

[0035] The technical problems involved in the present invention are solved by the following technical solutions: a microalloy steel plate and its normalizing rolling method, the mass percentage of its chemical composition is: C: 0.13% to 0.25%; Si: 0.1% to 0.4%; Mn : 1.85%~2.5%; P≤0.015%; S≤0.005%; V: 0.03%~0.08%; Cr: 0.05%~0.2%; N: 0.013%~0.017%, and the balance is Fe and unavoidable impurities.

[0036] Using converter + (LF+RH or VD) melting, using Si or Si-Mn alloy for deoxidation; [O]≤0.0015%. Nitrogen is added by blowing nitrogen and adding nitrogen-containing alloys in the refining process.

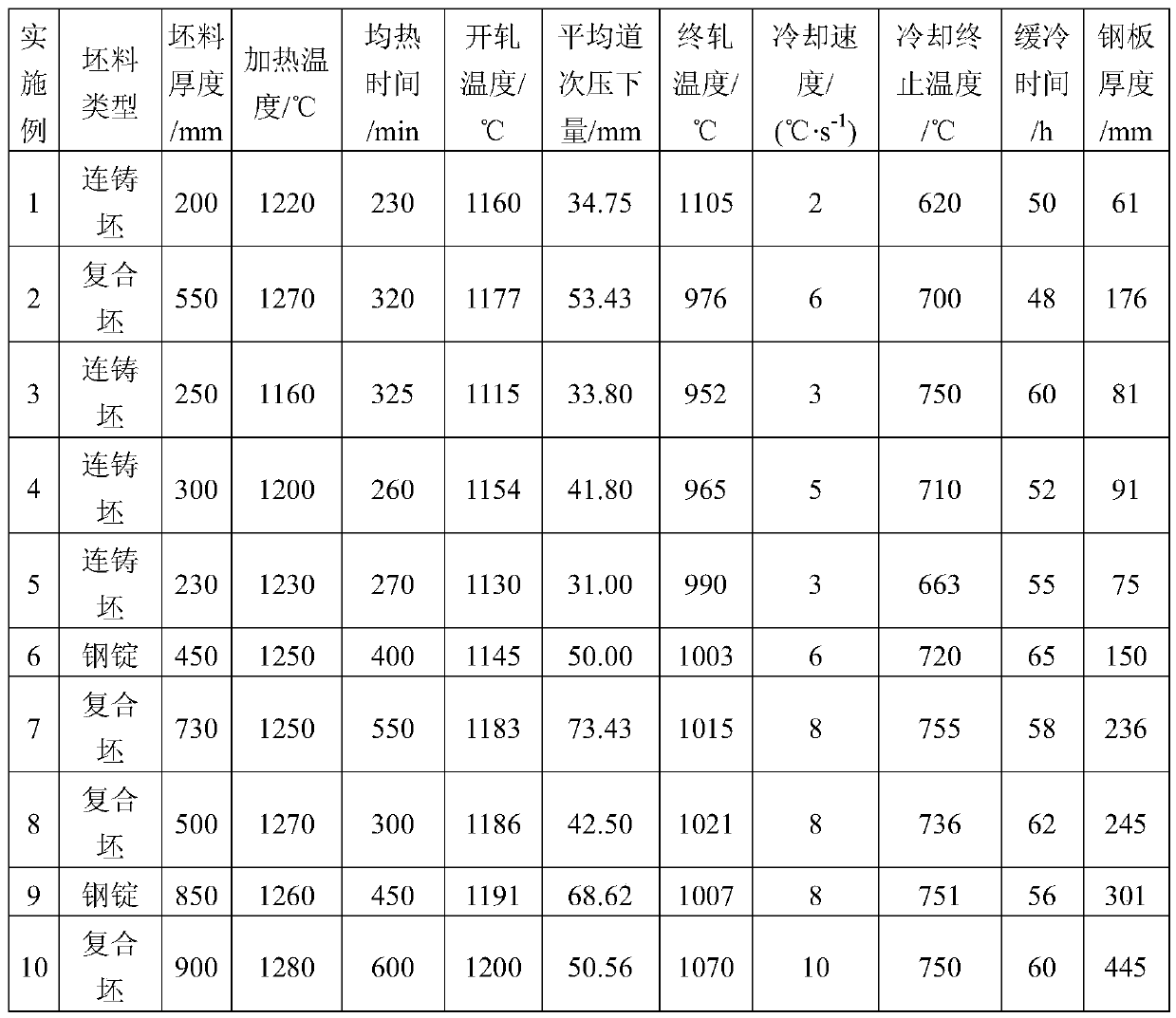

[0037] The billet heating temperature after continuous casting is 1150-1280°C, the soaking time is 200-600min, one-stage rolling is adopted, the starting rolling temperature is controlled at 1100-1200°C, the average pass reduction is 30-80mm, and the final rolling temperature is controlled At 950-1150°C. After the steel plate is rolled, it needs to be cooled by air cooling or wat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com