Adhesive resistance release paper for pressing flexible printed circuit board and preparation method of adhesive resistance release paper

A flexible circuit board, release paper technology, applied in special paper, printed circuit manufacturing, laminated printed circuit boards, etc., to achieve the effects of low viscosity, reduced operating procedures, and prevention of poor lamination and air bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

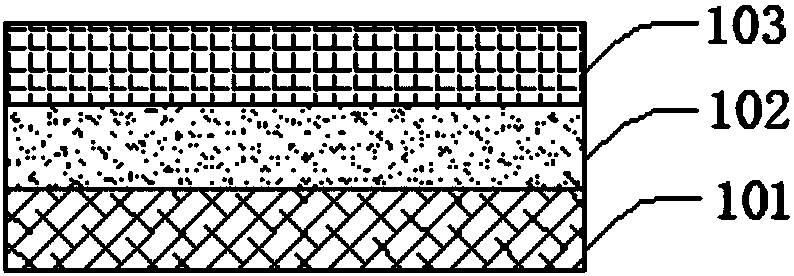

[0046] Embodiment 1: a kind of flexible printed circuit board is laminated with resisting glue release paper, such as image 3 As shown, including a base paper layer 101, a mixed adhesive layer 102 and a release layer 103, the mixed adhesive layer 102 is formed on the surface of the base paper layer 101, and the release layer 103 is formed on the upper surface of the mixed adhesive layer 102, And the mixed adhesive layer 102 bonds the base paper layer 101 and the release layer 103;

[0047] Described release layer is made of following raw material (by weight percentage):

[0048] TPX (poly-4-methylpentene): 70%;

[0049] PP (polypropylene): 30%;

[0050] The mixed adhesive layer is made of the following raw materials (in weight percent):

[0051] TPX (poly-4-methylpentene): 10%;

[0052] PP (polypropylene): 60%;

[0053] EMMA (ethylene-methyl methacrylate copolymer): 15%

[0054] PE (polyethylene): 15%.

[0055] The Vicat softening temperature of the laminated structure...

Embodiment 2

[0066] Embodiment 2: The structure of this embodiment is the same as that of Embodiment 1, and will not be repeated. The difference is that the release layer is made of the following raw materials (by weight): TPX: 80%; PP: 20%;

[0067] The mixed adhesive layer is made of the following raw materials (by weight): TPX: 20%; PP: 70%; EMMA: 5%; PE: 5%.

[0068] The thickness of the release layer 103 is 25 μm, the thickness of the mixed adhesive layer 102 is 60 μm, and the thickness of the base paper layer 101 is 60 μm.

Embodiment 3

[0069] Embodiment 3: The structure of this embodiment is the same as that of Embodiment 1, and will not be repeated. The difference is that the release layer is made of the following raw materials (by weight): TPX: 100%;

[0070] The mixed adhesive layer is made of the following raw materials (by weight): TPX: 30%; PP: 50%; EMMA: 8%; PE: 12%.

[0071] The release layer 103 has a thickness of 30 μm, the mixed adhesive layer 102 has a thickness of 50 μm, and the base paper layer 101 has a thickness of 120 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vicat softening temperature | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com