Synthesis method of liquid phase doped ternary precursor

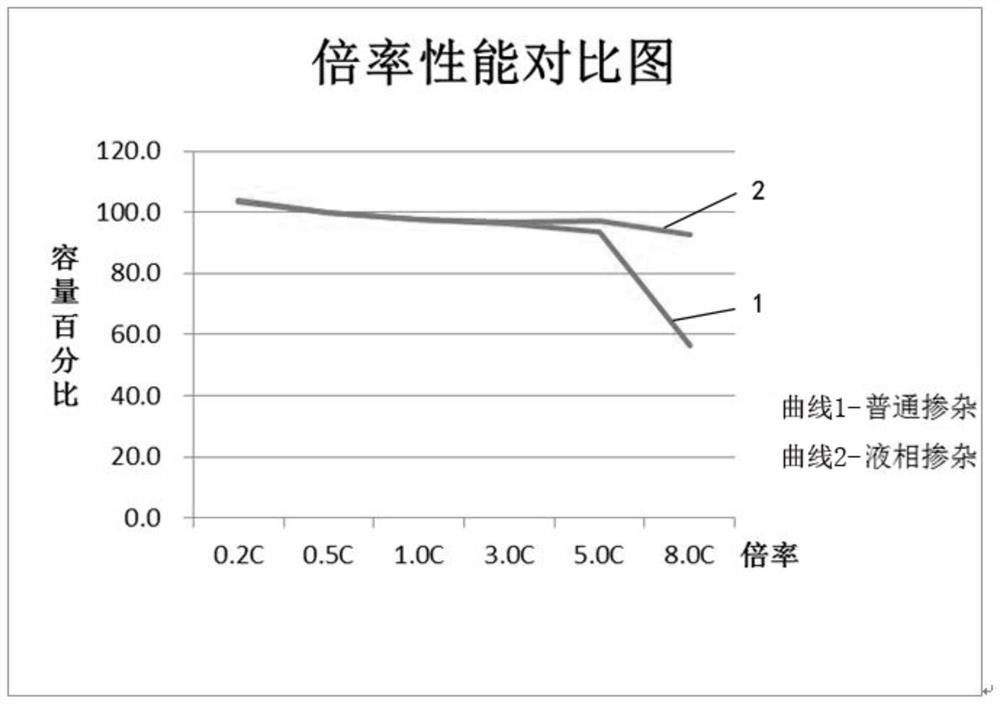

A synthesis method and precursor technology are applied in the synthesis field of liquid phase doping ternary precursors, which can solve the problems of inconvenient implementation, high production cost, long time consumption, etc., and achieve the solution of uneven mixing of materials and simple and feasible preparation method. , the effect of uniform particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

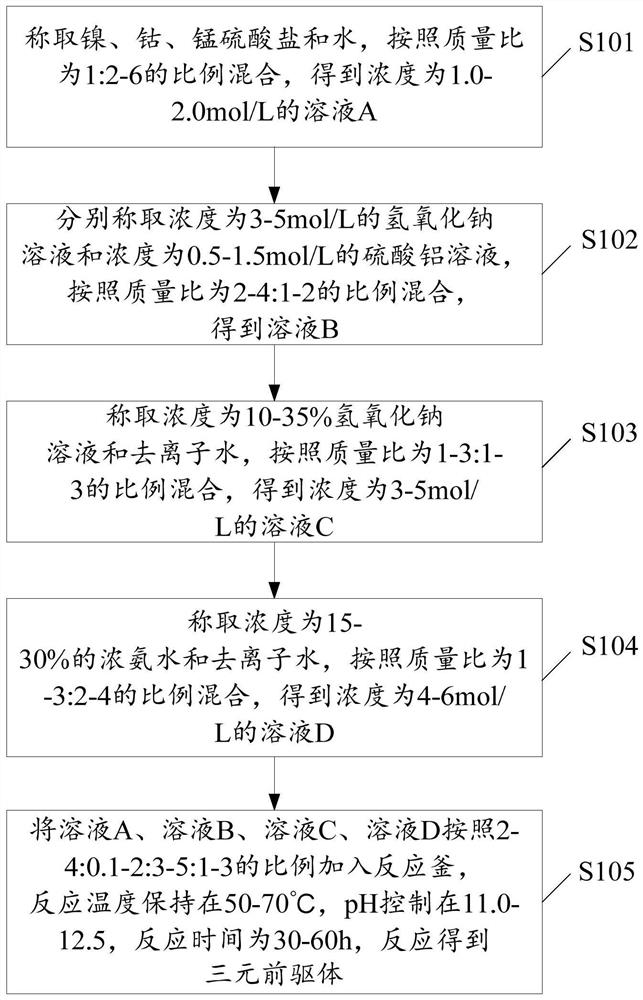

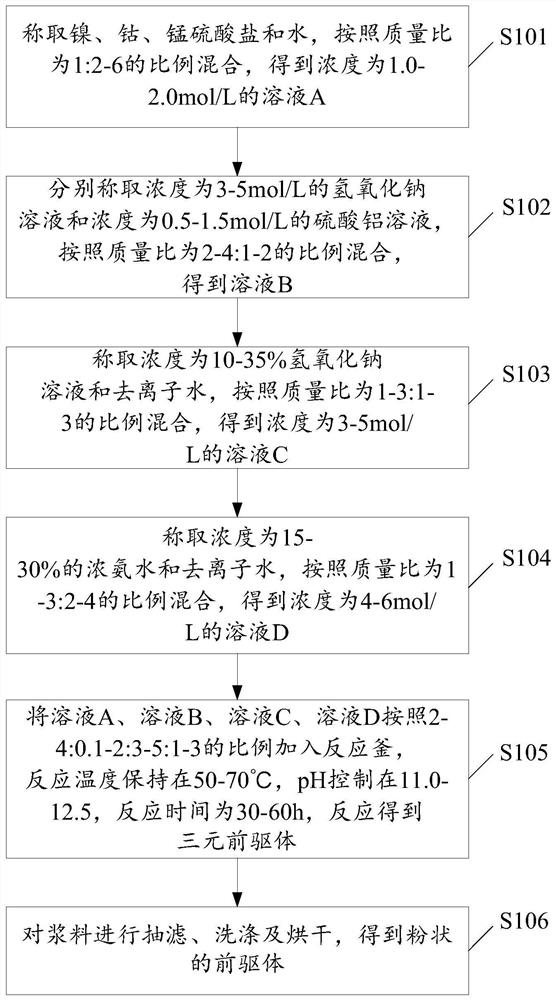

[0034] Such as figure 1 As shown, the present invention provides a kind of synthetic method of liquid phase doped ternary precursor, comprising:

[0035] S101. Weigh nickel, cobalt, manganese sulfate and water, and mix them according to a mass ratio of 1:2-6 to obtain a solution A with a concentration of 1.0-2.0 mol / L.

[0036] Preferably, nickel, cobalt, manganese sulfate and water are weighed and mixed according to a mass ratio of 1:3-5 to obtain solution A with a concentration of 1.0-1.5 mol / L.

[0037] More preferably, nickel, cobalt, manganese sulfate and water are weighed and mixed according to a mass ratio of 1:3-4 to obtain a solution A with a concentration of 1.1-1.4 mol / L.

[0038] S102. Weigh a sodium hydroxide solution with a concentration of 3-5 mol / L and an aluminum sulfate solution with a concentration of 0.5-1.5 mol / L, and mix them according to a mass ratio of 2-4:1-2 to obtain a solution B.

[0039] Preferably, the sodium hydroxide solution with a concentrat...

Embodiment 1

[0059] 1. Weigh 400g of nickel sulfate, 300g of cobalt sulfate, and 150g of manganese sulfate in 1700g of water, stir evenly to obtain a solution A with a concentration of 2.1mol / L.

[0060] 2. Take by weighing 20% sodium hydroxide solution and 200g of deionized water, stir to obtain a sodium hydroxide solution with a concentration of 5mol / L; weigh 100g of aluminum sulfate and 300g of deionized water, stir to obtain Aluminum sulfate solution with a concentration of 0.97 mol / L; weigh 300 g of the above-mentioned sodium hydroxide solution and 150 g of the aluminum sulfate solution, and stir to obtain solution B.

[0061] 3. Weigh 200 g of 15% sodium hydroxide solution and 200 g of deionized water to obtain solution C with a concentration of 3.75 mol / L.

[0062] 4. Weigh 120 g of concentrated ammonia water with a concentration of 25% and 200 g of deionized water to obtain a solution D with a concentration of 4.28 mol / L.

[0063] 5. Weigh 300g, 100g, 400g, and 200g of the above...

Embodiment 2

[0066] 1. Weigh 400g of nickel sulfate, 350g of cobalt sulfate, and 150g of manganese sulfate and dissolve them in 2700g of water, stir well to obtain solution A with a concentration of 1.39mol / L.

[0067] 2. Weigh 200g of 18% sodium hydroxide solution and 200g of deionized water, stir well to obtain a 4.5mol / L sodium hydroxide solution; weigh 100g of aluminum sulfate and 250g of deionized water, stir well Obtain an aluminum sulfate solution with a concentration of 1.17 mol / L; weigh 250 g of the above-mentioned sodium hydroxide solution and 150 g of the aluminum sulfate solution, and stir evenly to obtain solution B.

[0068] 3. Weigh 180 g and 200 g of 20% sodium hydroxide solution and 200 g of deionized water respectively to obtain solution C with a concentration of 4.5 mol / L.

[0069] 4. Weigh 120 g of concentrated ammonia water with a concentration of 25% and 200 g of deionized water to obtain a solution D with a concentration of 4.28 mol / L.

[0070] 5. Weigh 250g, 100g, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com