A kind of transparent silane-modified nano-montmorillonite dispersion liquid and its preparation method and application

A nano-montmorillonite, silane modification technology, applied in the direction of dyeing organosilicon compound treatment, fibrous filler, etc., can solve the problems of transparent non-water organic medium dispersion system report, application range and performance limitation, etc., to achieve operation The effect of easy, high production efficiency and simple reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

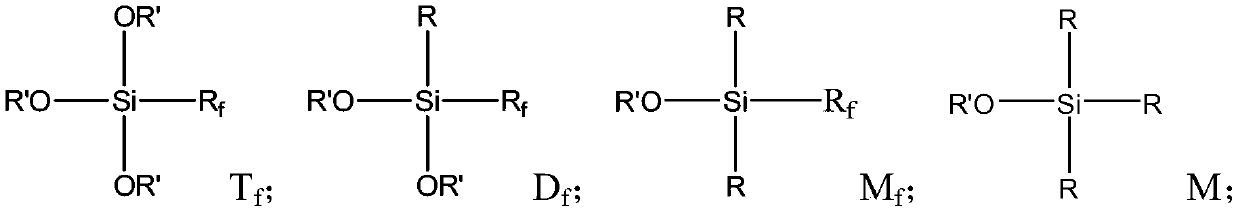

Method used

Image

Examples

Embodiment 1

[0067] 1.0 g of aqueous montmorillonite (clay) was added to 500 ml of deionized water while stirring to prepare a 0.2 wt % montmorillonite aqueous solution. Measure 0.15g of N-(2-aminoethyl)-isobutylmethyldimethoxysilane (molar mass: 220g / mol), add 15ml of methanol dropwise under stirring at room temperature to form a silane solution, mix well and then add dropwise 0.0012g deionized water, stirred at room temperature for 2h. Add the hydrolyzed N-(2-aminoethyl)-isobutylmethyldimethoxysilane dropwise to 0.2wt% montmorillonite aqueous solution with stirring at room temperature, stir for 1 hour, then start distillation, and slowly raise the temperature Add 2000ml of toluene dropwise while stirring during the high temperature process. During the heating process, there is no fraction until the temperature reaches 115°C. Distill until there is no fraction (about 4-5h), and the sample after removing the solvent (toluene, methanol, water) is obtained, and then The remaining solvent wa...

Embodiment 2

[0069]1.0 g of aqueous montmorillonite (clay) was added to 100 ml of deionized water while stirring to prepare a 1 wt % montmorillonite aqueous solution. Measure 6g of N-(2-aminoethyl)-isobutylmethyldimethoxysilane (molar mass: 220g / mol), add 6ml of ethanol dropwise under stirring at room temperature to form a silane solution, mix well and then add dropwise 0.98 g deionized water, stirred at room temperature for 2h. Add the hydrolyzed N-(2-aminoethyl)-isobutylmethyldimethoxysilane dropwise to 0.2wt% montmorillonite aqueous solution with stirring at room temperature, stir for 1 hour, then start distillation, and slowly raise the temperature Add 220ml of toluene dropwise while stirring during the high process, there is no fraction until the temperature reaches 115°C during the heating process, distill until there is no fraction (about 4-5h), and obtain the sample after removing the solvent (toluene, ethanol, water), and then The remaining solvent was completely removed by rotar...

Embodiment 3

[0071] 1.0 g of aqueous montmorillonite (clay) was added to 10 ml of deionized water while stirring to prepare a 10 wt % montmorillonite aqueous solution. Measure N-(2-aminoethyl)-isobutylmethyldimethoxysilane (molar mass is 220g / mol) 1g, N-(2-aminoethyl)-aminopropyltrimethoxysilane (molar mass (204g / mol) 1g, 15ml of methanol was added dropwise with stirring at room temperature to form a silane solution, after mixing, 6g of deionized water was added dropwise, and stirred at room temperature for 2h. Add the hydrolyzed N-(2-aminoethyl)-isobutylmethyldimethoxysilane and N-(2-aminoethyl)-aminopropyltrimethoxysilane dropwise to 10wt% under stirring at room temperature In the montmorillonite aqueous solution, stir for 1 hour, then start to distill, and add 70ml of dichloroethane dropwise while stirring while the temperature is slowly rising, there is no distillate in the heating process until the temperature reaches 110°C, distill until there is no distillate (about 4 -5h), obtain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com