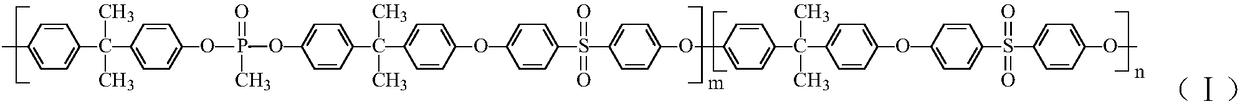

Phosphorus-containing flame-retardant engineering plastic PSU (polysulfone) and synthetic method thereof

A technology of engineering plastics and synthesis methods, which is applied in the field of polymer materials, can solve the problems of surface migration of flame retardants and poor mechanical properties of products, and achieve the effects of good flame retardancy, better flame retardancy, and high transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

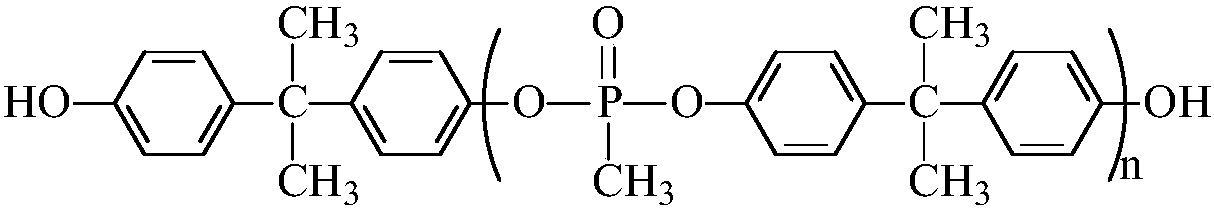

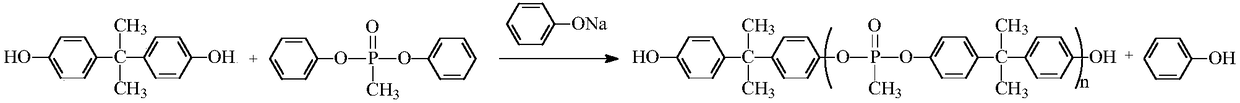

Method used

Image

Examples

Embodiment 1

[0044] A method for synthesizing phosphorus-containing flame-retardant engineering plastic polysulfone, comprising the following steps:

[0045] (1) drop into 120g bisphenol A, 6.53g diphenyl methylphosphonate (content 95%, 0.025mol) in the 1000mL there-necked flask device that distillation column and mechanical stirrer are housed, 5mg sodium phenoxide (NaOPh) catalyzer, Introduce nitrogen to discharge the air, heat the oil bath, raise the temperature of the reaction mixture to 240°C-250°C, keep it warm for 15 hours, collect about 5.3g of distillate during the reaction, cool to 140°C after the transesterification reaction , to obtain a mixture of reactive phosphorus-containing compounds and bisphenol A;

[0046] (2) In the above reaction product, under the condition of passing through dry nitrogen, add 143.50g 4,4'-dichlorodiphenyl sulfone (0.5mol), 64.00g sodium carbonate, 340.00g N,N'-dimethyl Acetamide, 80.00g xylene, stirred and dissolved, heated to 135-140°C and reacted ...

Embodiment 2

[0051] A method for synthesizing phosphorus-containing flame-retardant engineering plastic polysulfone, comprising the following steps:

[0052] (1) drop into 125.4g bisphenol A, 13.06g diphenyl methylphosphonate (content 95%, 0.05mol) in the 1000mL three-necked flask device that distillation column and mechanical stirrer are housed, 10mg sodium phenoxide (NaOPh) catalyst , feed nitrogen to discharge the air, heat the oil bath, raise the temperature of the reaction mixture to 240°C-250°C, keep the temperature for 15 hours, collect about 10.0g of distillate during the reaction, and cool to 140°C after the transesterification reaction °C, a mixture of reactive phosphorus-containing compounds and bisphenol A is obtained;

[0053] (2) In the above reaction product, under the condition of passing through dry nitrogen, add 143.50g 4,4'-dichlorodiphenyl sulfone (0.5mol), 64.00g sodium carbonate, 340.00g N,N'-dimethyl Acetamide, 80.00g xylene, stirred and dissolved, heated to 135-140...

Embodiment 3

[0058] A method for synthesizing phosphorus-containing flame-retardant engineering plastic polysulfone, comprising the following steps:

[0059] (1) drop into 131.1g bisphenol A, 19.59g diphenyl methylphosphonate (content 95%, 0.075mol) in the 1000mL three-necked flask device that distillation column and mechanical stirrer are housed, 15mg sodium phenoxide (NaOPh) catalyst , pass nitrogen gas to discharge the air, heat the oil bath, raise the temperature of the reaction mixture to 240°C-250°C, keep it warm for 15 hours, collect about 15.0g of distillate during the reaction, cool to 140°C after the transesterification reaction °C, a mixture of reactive phosphorus-containing compounds and bisphenol A is obtained;

[0060] (2) In the above reaction product, 143.50g of 4,4'-dichlorodiphenyl sulfone (0.5mol), 70.00g of sodium carbonate, 340.00g of N,N'-dimethyl Acetamide, 80.00g xylene, stirred and dissolved, heated to 135-140°C and reacted for 3 hours. During the reaction, the wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com