Positively-charged carbon dot, and preparation method and application thereof

A positively charged, carbon dot technology, applied in the fields of botanical equipment and methods, applications, chemical instruments and methods, etc., can solve the problems of poor controllability of carbon dot size, complex preparation process, high cost, and achieve high selectivity, high The effect of simple preparation process and short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Preparation of carbon dots by microwave wet heat method:

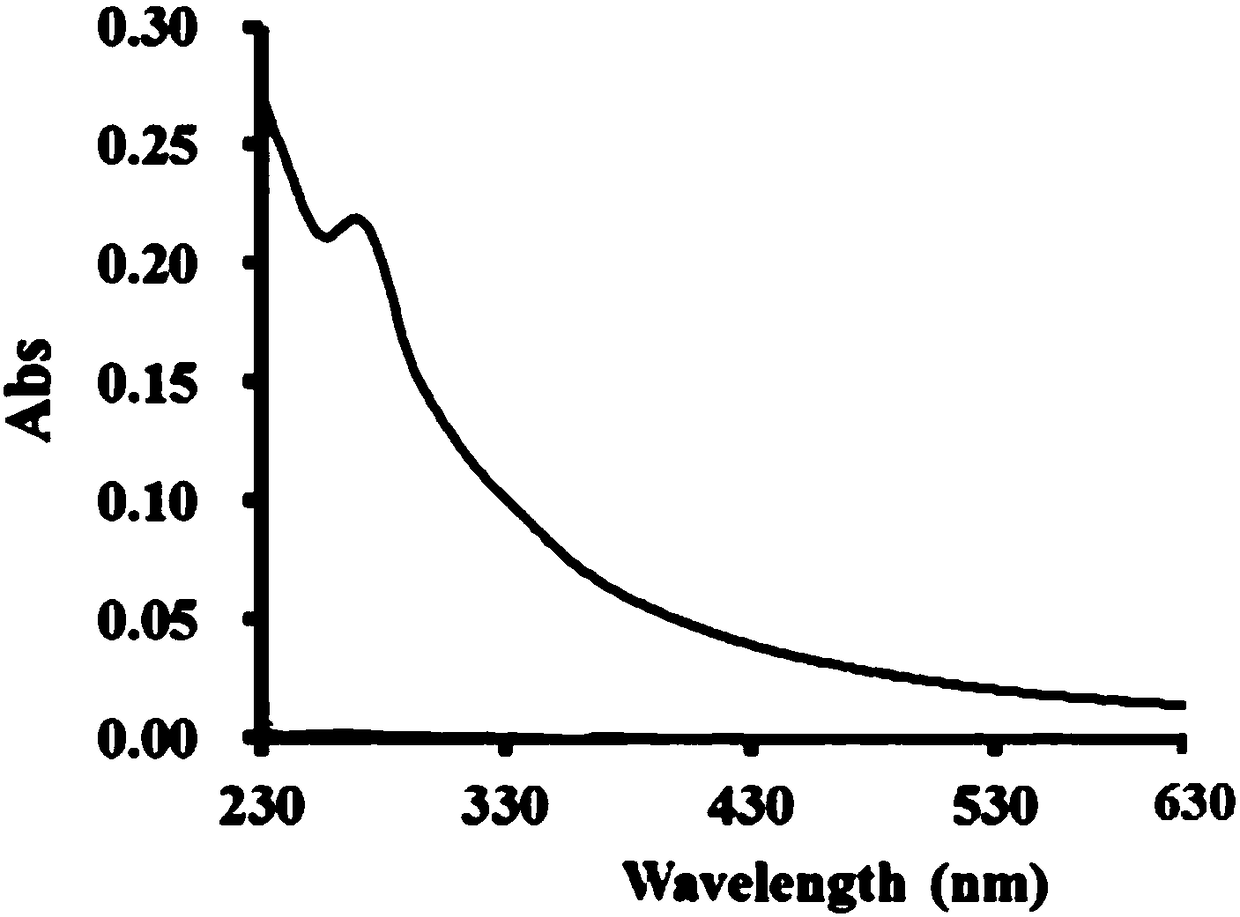

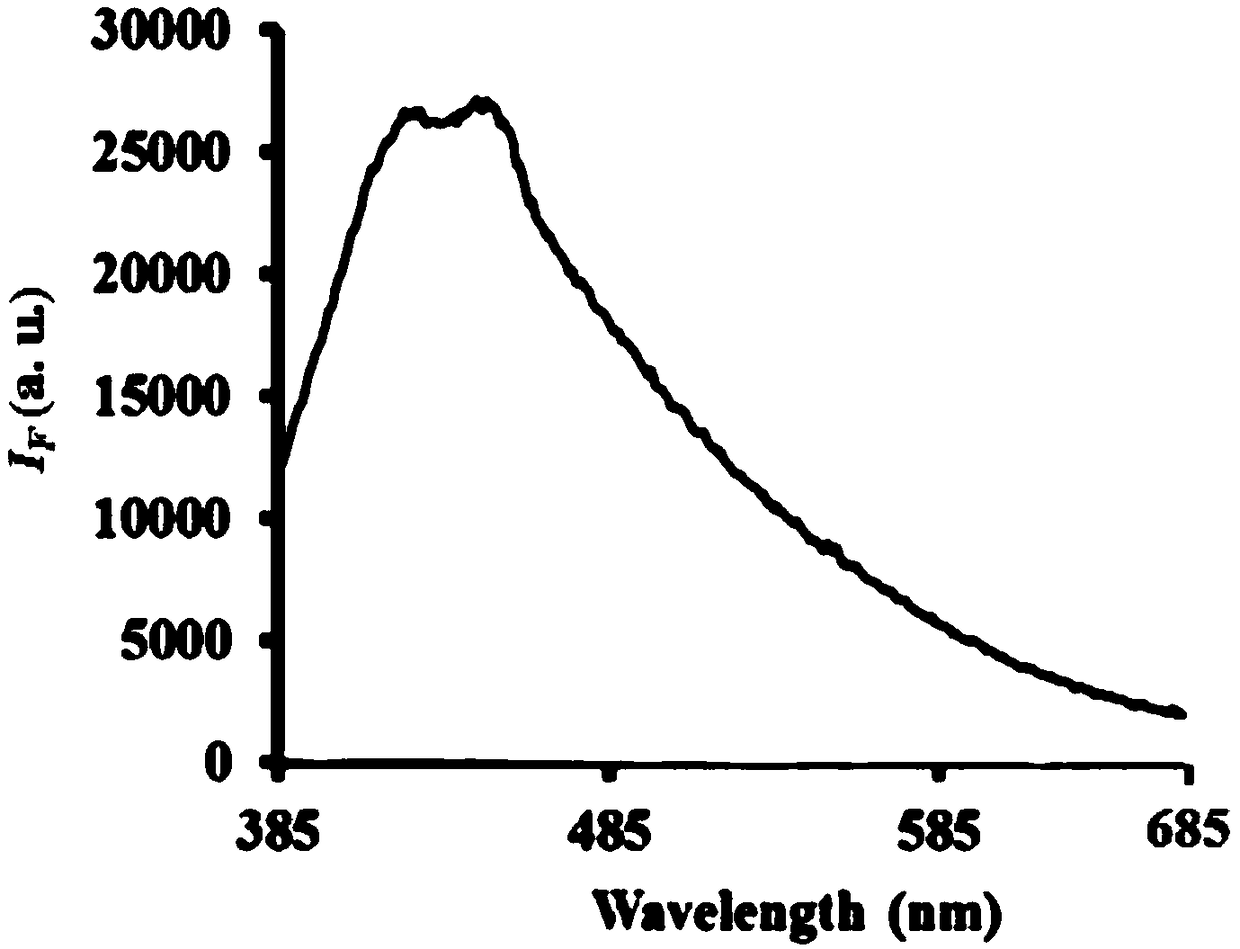

[0032] Weigh 1 g of polylysine, dissolve it in 6 mL of deionized water and stir it ultrasonically. Put the mixed polylysine aqueous solution in a round-bottomed flask, place it in a microwave field and heat it for 7-10 minutes. After fully reacting, stop heating and cool down to room temperature naturally. Dissolve the above liquid in 5mL deionized water, and act in the ultrasonic field for a period of time to dissolve all the obtained carbon dots in water; centrifuge to remove insoluble precipitates and large particle size aggregates, and clarify the carbon dot aqueous solution through a 0.25μm ultrafine membrane After dialysis, a light yellow clear and transparent solution was obtained. The clear carbon dot solution was placed in a freeze-dryer, and after freeze-drying, it was made into carbon dot powder. The carbon dot powder was collected and stored at 4°C for future use. The yield was 40%.

[0033] Wherein...

Embodiment 2

[0042] Preparation of carbon dots by microwave wet heat method:

[0043]Weigh 1 g of polylysine, dissolve it in 6 mL of deionized water and stir it ultrasonically. Put the mixed polylysine aqueous solution in a round-bottomed flask, place it in a microwave field and heat it for 7-10 minutes. After fully reacting, stop heating and cool down to room temperature naturally. Dissolve the above liquid in 5mL deionized water, and act in the ultrasonic field for a period of time to dissolve all the obtained carbon dots in water; centrifuge to remove insoluble precipitates and large particle size aggregates, and clarify the carbon dot aqueous solution through a 0.25μm ultrafine membrane After dialysis, a light yellow clear and transparent solution was obtained. The clear carbon dot solution was placed in a freeze dryer, and after freeze drying, carbon dot powder was made. The carbon dot powder was collected and stored at 4°C for later use. The yield was about 42%.

[0044] Wherein, th...

Embodiment 3

[0046] Preparation of carbon dots by microwave wet heat method:

[0047] Weigh 1 g of polylysine, dissolve it in 6 mL of deionized water and stir it ultrasonically. Put the mixed polylysine aqueous solution in a round-bottomed flask, place it in a microwave field and heat it for 7-10 minutes. After fully reacting, stop heating and cool down to room temperature naturally. Dissolve the above liquid in 6mL deionized water, and act in the ultrasonic field for a period of time to dissolve all the obtained carbon dots in water; centrifuge to remove insoluble precipitates and large particle size aggregates, and clarify the carbon dot aqueous solution through a 0.25μm ultrafine membrane After dialysis, a light yellow clear and transparent solution was obtained. The clear carbon dot solution was placed in a freeze-dryer, and after freeze-drying, it was made into carbon dot powder. The carbon dot powder was collected and stored at 4°C for later use. The yield was about 33%.

[0048] Wh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com