Zero-valent iron-iron copper microelectrolysis filler and preparation method thereof

A technology of zero-valent iron and micro-electrolysis, applied in chemical instruments and methods, water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems such as compaction, improve packing compaction, efficient wastewater treatment capacity, reduce The effect of contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

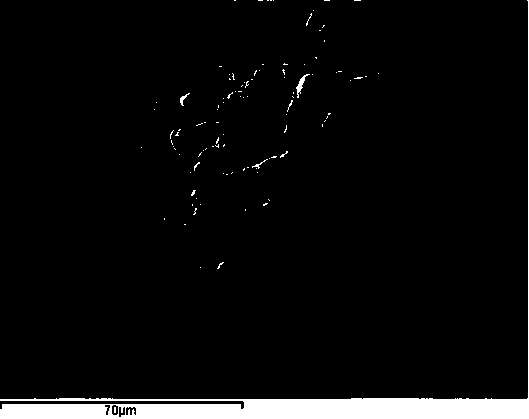

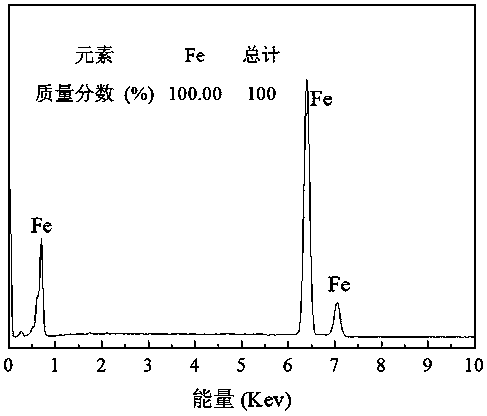

[0036] A zero-valent iron-iron-copper micro-electrolytic filler, comprising zero-valent iron and iron-copper uniformly mixed with a mass ratio of 1:1; the zero-valent iron is zero-valent iron with an average particle size of 100 μm after derusting, cleaning and drying pink.

[0037] Its preparation method specifically comprises the following steps:

[0038] Step A: Preparation of Iron Copper

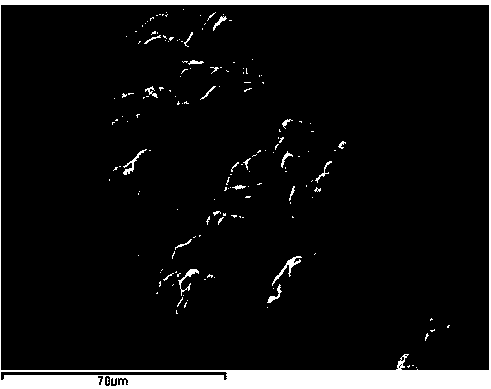

[0039] Use deionized water to prepare a plating solution with a copper sulfate concentration of 20 g / L and a disodium edetate concentration of 7 g / L, and place the zero-valent iron powder with an average particle size of 100 μm after derusting, cleaning and drying In the plating solution, react at 30°C for 10 min at a stirring speed of 250 rpm to form a uniform and dense copper layer on the surface of zero-valent iron to obtain iron-copper.

[0040] Step B: Wash and Dry

[0041] The iron-copper obtained in step A is cleaned with deionized water to remove the plating solution on the su...

Embodiment 2

[0060] A zero-valent iron-iron-copper micro-electrolytic filler, comprising zero-valent iron and iron-copper whose mass ratio is 3:1 and uniformly mixed; said zero-valent iron is zero-valent iron with an average particle diameter of 2mm after derusting, cleaning and drying particles.

[0061] Its preparation method specifically comprises the following steps:

[0062] Step A: Preparation of Iron Copper

[0063] With deionized water preparation cupric chloride concentration is that 42 g / L and sodium citrate concentration are the plating solution of 46 g / L, and the zero-valent iron particle of mean particle diameter 2mm after derusting cleaning and drying is placed in plating solution , reacted at 50°C for 30 minutes at a stirring speed of 250 rpm to form a uniform and dense copper layer on the surface of zero-valent iron particles to obtain iron-copper.

[0064] Step B: Wash and Dry

[0065] Wash the iron and copper obtained in step A with distilled water to remove the platin...

Embodiment 3

[0069] A zero-valent iron-iron-copper micro-electrolytic filler, comprising zero-valent iron and iron-copper uniformly mixed with a mass ratio of 0.3:1; the zero-valent iron is zero-valent iron with an average particle diameter of 100 μm after derusting, cleaning and drying pink.

[0070] Its preparation method specifically comprises the following steps:

[0071] Step A: Preparation of Iron Copper

[0072] Use deionized water to prepare a plating bath whose copper sulfate concentration is 2 g / L and sodium tartrate concentration is 7 g / L, and place the zero-valent iron powder with an average particle diameter of 100 μm after derusting, cleaning and drying in the plating bath. A uniform and dense copper layer was formed on the surface of the zero-valent iron powder by reacting at 5°C for 20 minutes at a stirring speed of 300 rpm to obtain iron-copper.

[0073] Step B: Wash and Dry

[0074] Wash the iron and copper obtained in step A with distilled water to remove the plating ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com