Road asphalt anti-aging agent and preparation method thereof

A technology of road asphalt and anti-aging agent, which is used in building components, building thermal insulation materials, buildings, etc., can solve the problems of limited all-weather aging resistance of asphalt, poor water-damage resistance of anti-aging asphalt, and high price, and achieve all-weather resistance of road asphalt. Good aging performance, improved all-weather aging resistance, low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

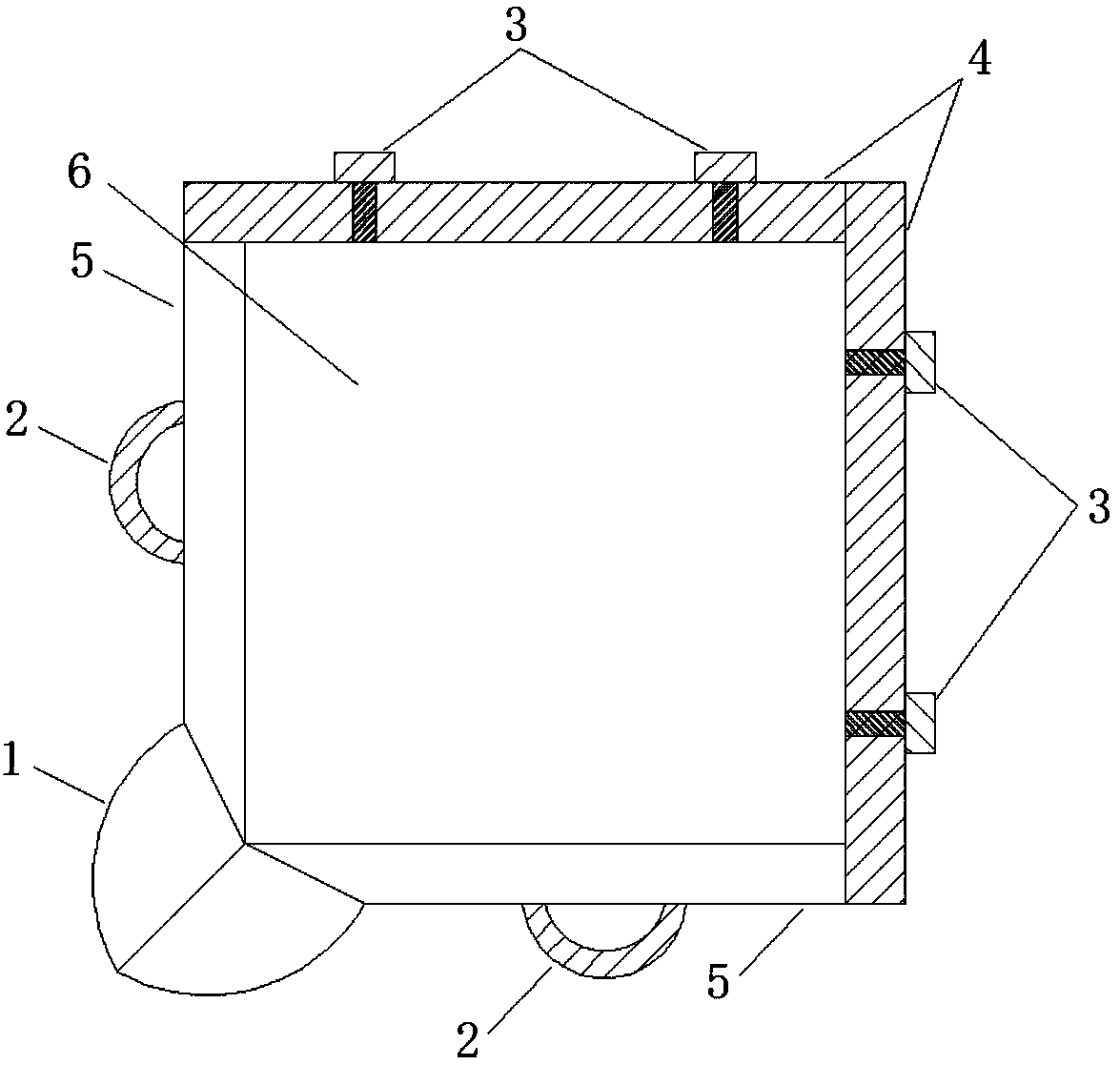

Image

Examples

preparation example Construction

[0032] A preparation method of road asphalt anti-aging agent, comprising the following steps:

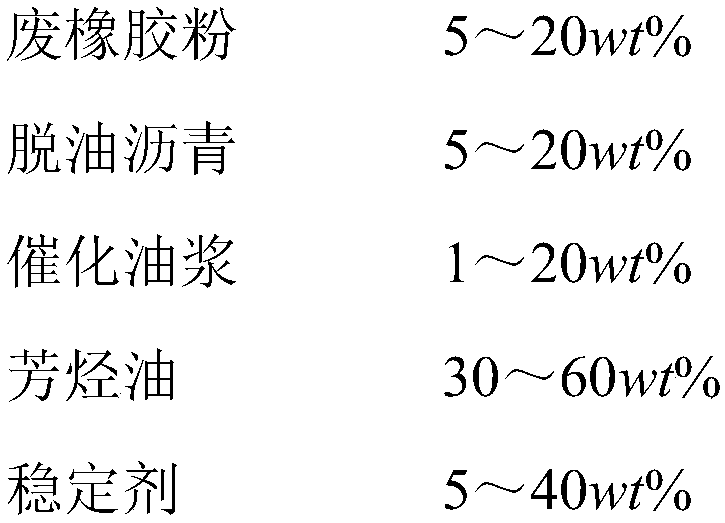

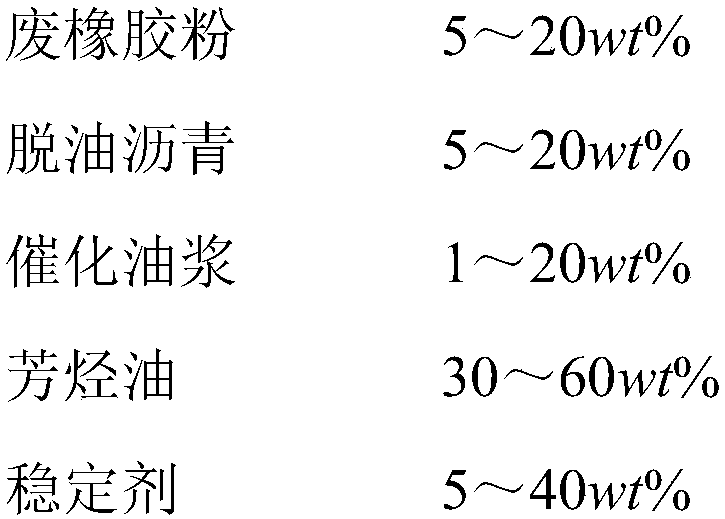

[0033] (1) After mixing the nano-calcium carbonate, carbonamide, aromatic amine antioxidant and zinc oxide with a weight ratio of 5-30:15-55:20-60:5-40, prepare a stabilizer with uniform particles ;

[0034] (2) Mix the catalytic oil slurry and aromatic oil and heat it to a molten state, then add waste rubber powder and deoiled asphalt and mix and swell, and finally add the stabilizer obtained in step (1) and stir evenly to obtain road asphalt anti-aging agent, wherein the weight ratio of catalytic oil slurry, aromatic oil, waste rubber powder, deoiled asphalt, and stabilizer is 1-20:30-60:5-20:5-20:5-40.

[0035] In the preparation method provided by the present invention, the stabilizer prepared into uniform particles can be prepared into uniform fine particles by using an extruder. Preferably, the particle length of the stabilizer is in the range of 0.5-5mm.

[0036] A prepara...

Embodiment 1

[0048] Embodiment 1 illustrates the composition and preparation method of road asphalt antiaging agent.

[0049] Weigh 12g of nano-calcium carbonate, 33g of carbonamide, 40g of aromatic amine antioxidant, and 15g of zinc oxide, mix the above ingredients uniformly at room temperature, and prepare them into 1mm-long thin strips through an extruder to obtain the stabilizer , labeled WDJ1, spare.

[0050] Weigh 10g of catalytic oil slurry and 108g of aromatic oil respectively and pour them into a heatable vessel, and heat the mixture of 10g of catalytic oil slurry and 108g of aromatic oil to 175°C. 24g of 60-80 mesh waste automobile tire rubber powder was added thereto, and the temperature was maintained at 175° C. and stirred for 2 hours to fully swell the waste tire rubber powder. At this time, 16 g of deoiled asphalt with a softening point of 90° C. was added and stirred for 1 hour at a temperature of 175° C. to completely dissolve the deoiled asphalt. Add 42g of WDJ1 into th...

Embodiment 2

[0052] Weigh 16g of catalytic oil slurry and 102g of aromatic oil respectively and pour them into a heatable vessel, and heat the mixture of 16g of catalytic oil slurry and 102g of aromatic oil to 175°C. 28g of 60-80 mesh waste automobile tire rubber powder was added thereto, and the temperature was maintained at 175° C. and stirred for 3 hours to fully swell the waste tire rubber powder. At this point, 12 g of deoiled asphalt with a softening point of 90° C. was added and stirred for 1 hour at a temperature of 175° C. to completely dissolve the deoiled asphalt. Add 42g of WDJ1 into the above mixture, and continue stirring for 1.5h to make it completely mixed to obtain an anti-aging agent, marked as KLJ2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com