Antibacterial HIPS (High Impact Polystyrene) plastic

An antibacterial and plastic technology, applied in the field of antibacterial plastics, can solve the problems of rare HIP plastics, harsh processing site environment, and only suitable processing methods, and achieve the effects of daily application, good antibacterial effect, and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

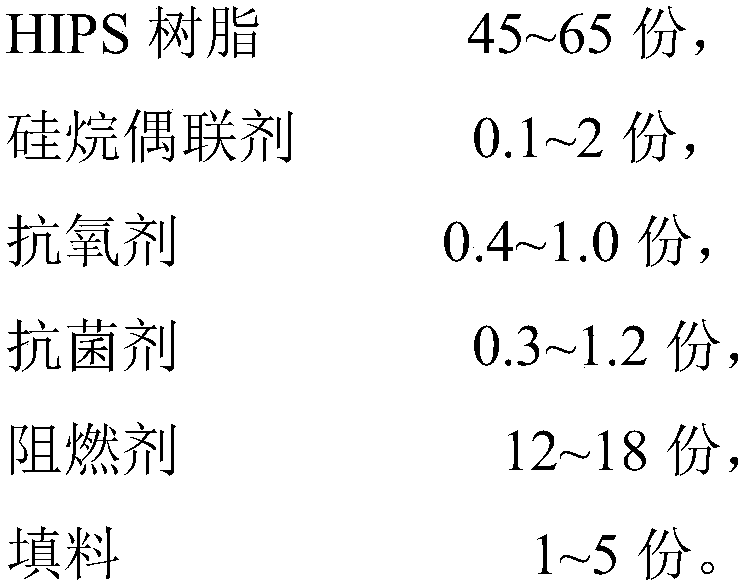

[0040] A kind of antibacterial HIPS plastic: be made of following raw material by weight:

[0041]

[0042] The HIPS resin is a butadiene-styrene graft copolymer, and the specific parameters are shown in Table 1.

[0043] The silane coupling agent is γ-(2,3-glycidoxy)propyltrimethoxysilane.

[0044] The antioxidant is tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionic acid]pentaerythritol ester and 2-(2'-hydroxyl-5'-tert-octylphenyl)benzene Triazoles are mixed in a mass ratio of 3:1.

[0045] The filler is formed by mixing talcum powder and calcium carbonate at a mass ratio of 1:3.

[0046] The antibacterial agent is prepared by mixing nano-silver and Melaleuca alternifolia oil in a mass ratio of 1:3.

[0047] Melaleuca alternifolia oil: mainly from Melaleuca alternifolia, Melaleuca alternifolia, woody plant. Its extracted oil has strong antibacterial, bactericidal and antibacterial effects.

[0048] The flame retardant is hollow mesoporous nanometer modified by c...

Embodiment 2

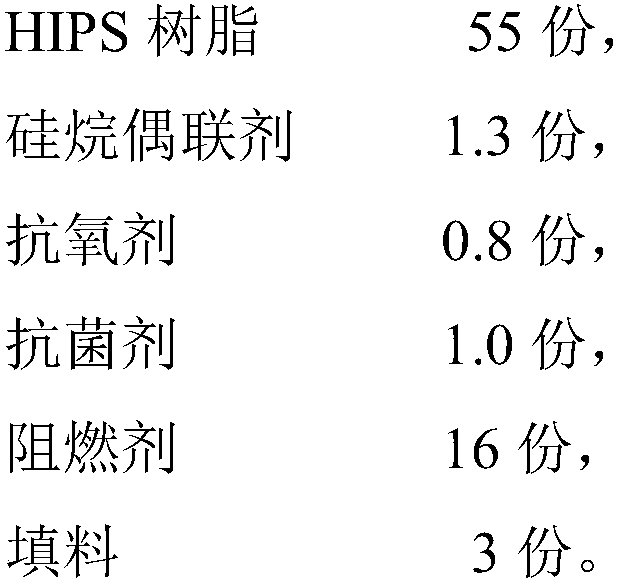

[0052] A kind of antibacterial HIPS plastic: be made of following raw material by weight:

[0053]

[0054] The HIPS resin is a butadiene-styrene graft copolymer, and the specific parameters are shown in Table 1.

[0055] The silane coupling agent is γ-(2,3-glycidoxy)propyltrimethoxysilane.

[0056] The antioxidant is tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate]pentaerythritol ester.

[0057] The filler is formed by mixing talcum powder and calcium carbonate at a mass ratio of 1:3.

[0058] The antibacterial agent is nano silver.

[0059] The flame retardant is melamine-modified polyphosphazene.

[0060] The preparation method of the melamine-modified polyphosphazene is as follows: Weigh 1.06g of melamine and 1.94g of 4,4'-diaminodiphenyl ether into 360mL of pyridine. Ultrasound for 10min at a power of 200W to obtain solution A; dissolve 2.0g of trimeric phosphazene chloride in 20mL pyridine under ice bath at 0°C and magnetic stirring at 200r / min to obtain ...

Embodiment 3

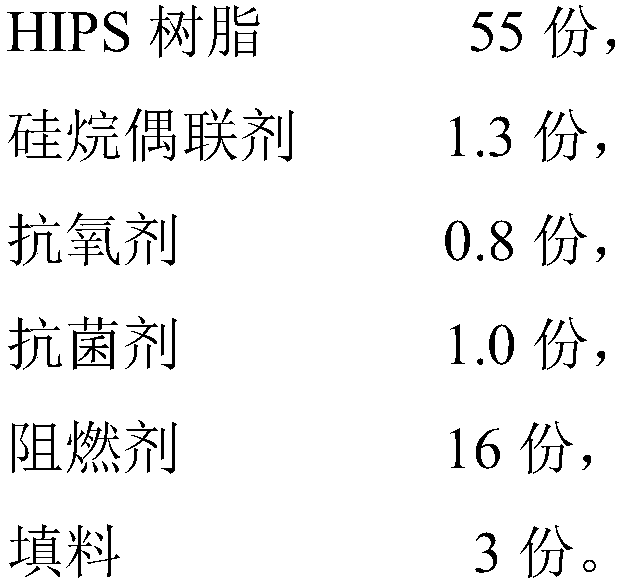

[0063] A kind of antibacterial HIPS plastic: be made of following raw material by weight:

[0064]

[0065] The HIPS resin is a butadiene-styrene graft copolymer, and the specific parameters are shown in Table 1.

[0066] The silane coupling agent is γ-(2,3-glycidoxy)propyltrimethoxysilane.

[0067] The antioxidant is tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate]pentaerythritol ester.

[0068] The filler is formed by mixing talcum powder and calcium carbonate at a mass ratio of 1:3.

[0069] The antibacterial agent is Melaleuca alternifolia oil.

[0070] Melaleuca alternifolia oil: mainly from Melaleuca alternifolia, Melaleuca alternifolia, woody plant. Its extracted oil has strong antibacterial, bactericidal and antibacterial effects.

[0071] The flame retardant is melamine-modified polyphosphazene.

[0072] The preparation method of the melamine-modified polyphosphazene is as follows: Weigh 1.06g of melamine and 1.94g of 4,4'-diaminodiphenyl ether into 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com