Antifouling paint based on urushiol benzoxazine copper polymer and preparation method of antifouling paint

A technology of benzoxazine copper and antifouling paint, applied in antifouling/underwater paint, coating, paint containing biocide, etc. wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

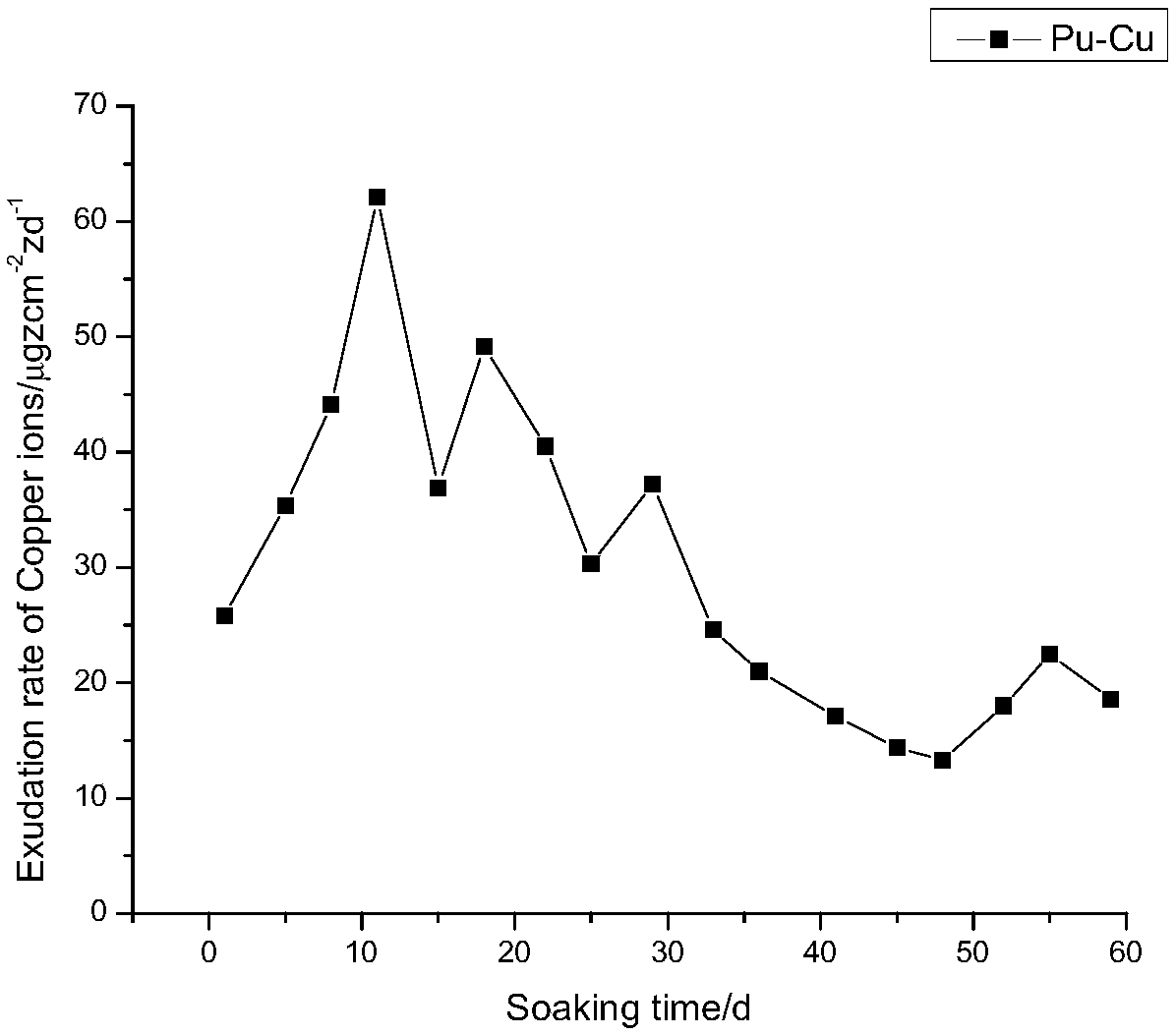

Image

Examples

preparation example Construction

[0017] The present invention also relates to a kind of preparation method of the above-mentioned antifouling coating based on urushiol benzoxazine copper polymer, comprising the following steps:

[0018] Weigh cuprous oxide, auxiliary antifouling agent, antibacterial agent, auxiliary agent and solvent according to the above-mentioned parts by weight, and carry out the first dispersion treatment after mixing until the fineness of the mixed raw materials is below 100 μm, and then press the above-mentioned The urushiol benzoxazine copper polymer solution is weighed in parts by weight and added to the mixed raw materials for the second dispersion treatment to obtain the antifouling coating based on the urushiol benzoxazine copper polymer.

[0019] As can be seen from the foregoing description, the beneficial effects of the present invention are:

[0020] The invention adopts the urushiol-type benzoxazine copper polymer as the film-forming material of the antifouling paint, and the...

Embodiment 1

[0041] The preparation method of the antifouling coating based on the urushiol benzoxazine copper polymer of the present embodiment may further comprise the steps:

[0042] (1) Urushiol-type benzoxazine based on octylamine was prepared from urushiol, paraformaldehyde and octylamine by Mannich condensation reaction, and urushiol-type benzoxazine based on octylamine and anhydrous copper chloride Preparation of urushiol-type benzoxazine copper polymer based on octylamine after the reaction;

[0043] The urushiol-type benzoxazine copper polymer based on octylamine is dissolved in xylene, and the weight ratio of the urushiol-type benzoxazine copper polymer based on octylamine to xylene is 1:2, and the obtained based on Urushiol-type benzoxazine copper polymer solution of octylamine;

[0044](2) Weigh 0 parts of cuprous oxide, 5 parts of auxiliary antifouling agent, 5 parts of antibacterial agent, 3 parts of auxiliary agent and 20 parts of solvent in parts by weight, add them to th...

Embodiment 2

[0047] The preparation method of the antifouling coating based on the urushiol benzoxazine copper polymer of the present embodiment may further comprise the steps:

[0048] (1) Urushiol-type benzoxazine based on octylamine was prepared from urushiol, paraformaldehyde and octylamine by Mannich condensation reaction, and urushiol-type benzoxazine based on octylamine and anhydrous copper chloride Preparation of urushiol-type benzoxazine copper polymer based on octylamine after the reaction;

[0049] The urushiol-type benzoxazine copper polymer based on octylamine is dissolved in xylene, and the weight ratio of the urushiol-type benzoxazine copper polymer based on octylamine to xylene is 1:2, and the obtained based on Urushiol-type benzoxazine copper polymer solution of octylamine;

[0050] (2) Weigh 5 parts of cuprous oxide, 5 parts of auxiliary antifouling agent, 5 parts of antibacterial agent, 3 parts of auxiliary agent and 25 parts of solvent in parts by weight, add them to t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com