Concrete coating protecting system and construction method

A protective system and concrete technology, applied in coatings, polyamide coatings, polyurea/polyurethane coatings, etc., can solve the problem of low tensile strength and elongation of the reinforcement layer, no detailed description of flexibility, and limited improvement of flexibility problems such as improved compactness, reduced risk of cracking, and increased strength of the base

Active Publication Date: 2018-07-06

CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +2

View PDF6 Cites 10 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

These materials generally have the disadvantages of short protection life, high maintenance cost, and poor environmental protection.

Especially when there are cracks in the concrete base, the protective coating on the surface will crack and lose its protective effect.

[0005] Chinese patent CN101456756A discloses "concrete structure heavy-duty anti-corrosion nano-composite coating and protective method", which includes nano-modified epoxy sealing coating, nano-modified epoxy miracic iron intermediate paint, nano-modified fluorine-containing polyurethane topcoat or Silicone acrylic topcoat or fluorine-containing polysiloxane topcoat improves the adhesion and anti-corrosion life of the protection system. However, there is no detailed description on flexibility. The protection system corresponds to the matching thickness and construction method of traditional anti-corrosion coatings, and According to the description of the chemical composition and other properties of each layer of coating, it can be judged that the improvement of its flexibility is very limited

[0006] The Chinese application with the publication number CN107337993A discloses "a rapid construction high-durability concrete protection system and its preparation method". The protection system improves construction efficiency and environmental adaptability. The tensile strength and elongation of the layer are still relatively low, the tensile strength is 4.2-4.6MPa, the elongation is 11-22%, the tensile strength of the surface layer is 12.5-13.8MPa, and the elongation is 98-110%, so once the base layer Cracks occur, the risk of the protective coating cracking along with the base layer is still relatively high

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

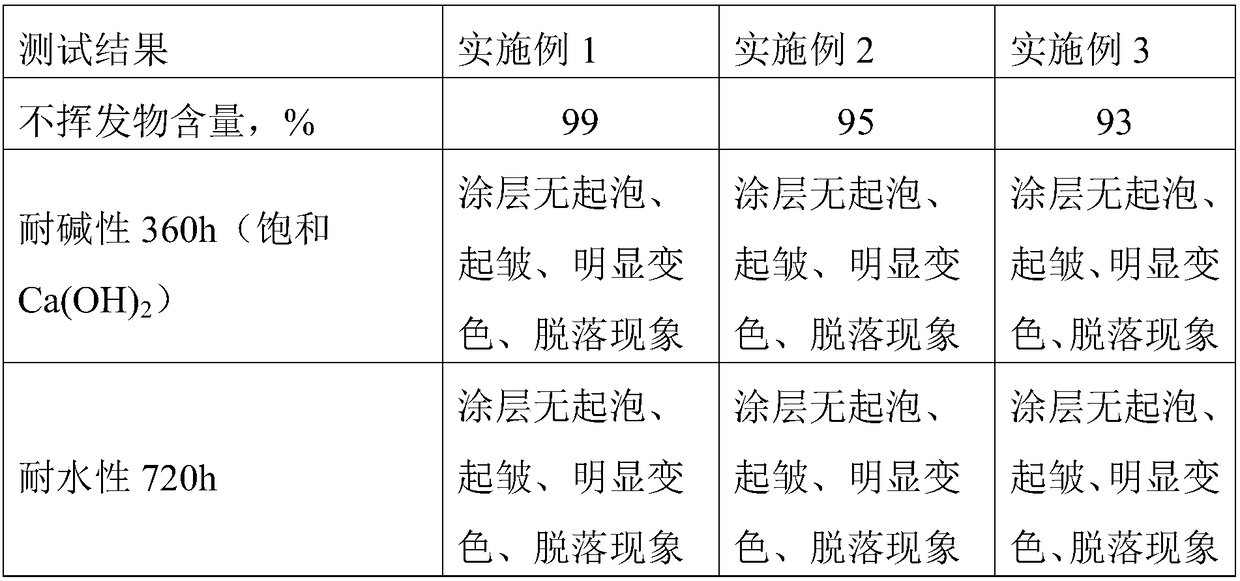

Embodiment 1~3

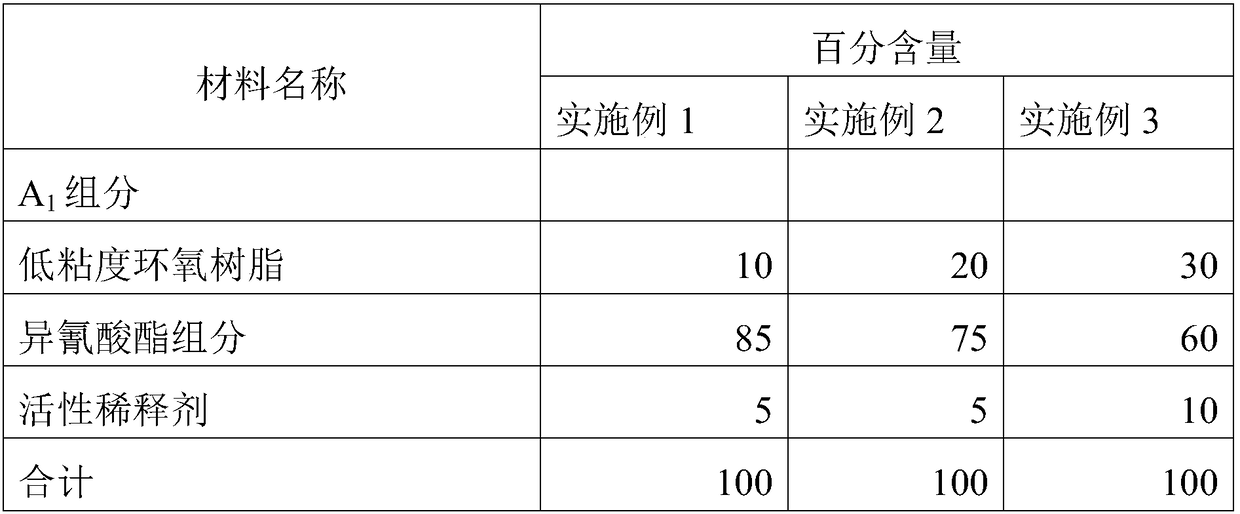

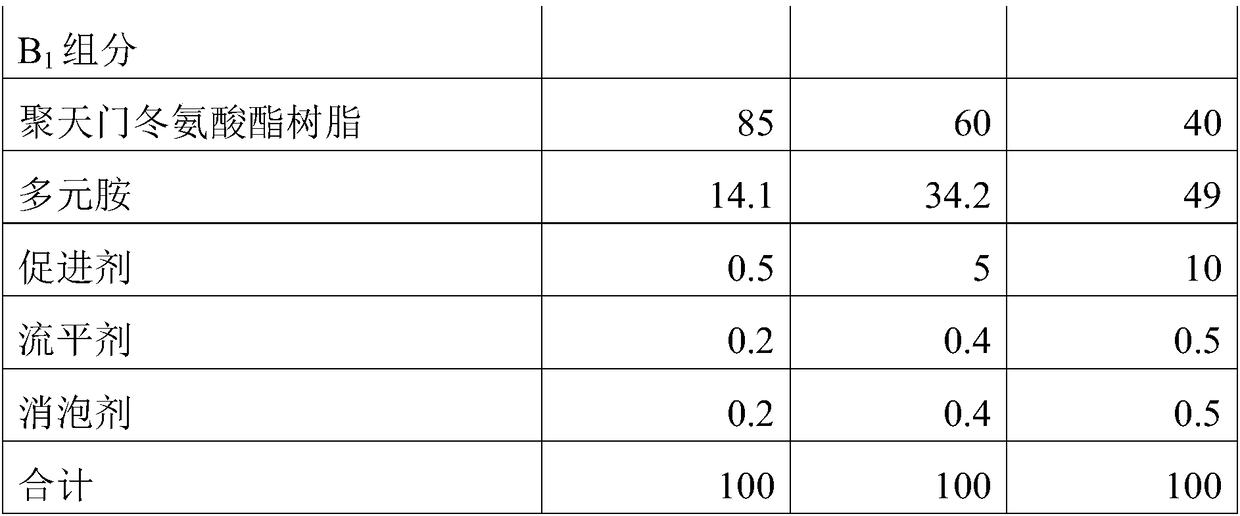

[0051] Penetrating primer formula composition in the embodiment of the present invention 1~3 is as shown in table 1:

[0052] Formulation of table 1 penetrating primer

[0053]

[0054]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a concrete coating protecting system. The concrete coating protecting system comprises a concrete permeating type primer and a high-build weather-resistant finishing coat, wherein the permeating type primer comprises a component A1 and a component B1 with the mass ratio of 3-1 to 1-1; the high-build weather-resistant finishing coat comprises a component A2 and a component B2 with the mass ratio of 1-3 to 3-1. The invention also provides a construction method. According to the concrete coating protecting system, the permeating type primer is capable of improving the intensity of a foundation and preventing the foundation form cracking; the high-build weather-resistant finishing coat is high in solid content, low in viscosity, environmentally friendly, fast to cure, short in period, high in tensile strength and elongation percentage, and outstanding in pursuit performance. Therefore, the concrete coating protecting system is outstanding in alkali resistance, ageing resistance, resist to chloride ion penetration, and capable of prolonging the service life of a concrete structure.

Description

technical field [0001] The invention relates to the technical field of construction, in particular to a concrete coating protection system and a construction method. Background technique [0002] The basic way of anti-corrosion of reinforced concrete building structure is to maximize the anti-chloride ion permeability of concrete itself by optimizing design and construction to limit the penetration of environmental corrosive media (chloride, oxygen and water, etc.) into concrete, thereby preventing steel corrosion. Mainly include: Properly increase concrete strength and cement dosage, apply high-performance concrete, ensure the thickness of steel bar protective layer, avoid cracking or strictly control the width of cracks, improve the compactness of concrete, add anti-corrosion agent for steel bar, external coating protection, coating (Plating) layers of steel bars, cathodic protection, etc. [0003] Concrete surface coating protection is the most effective and economical p...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C09D177/00C09D175/04C09D7/62C09D7/65E04F13/02

CPCC08K2003/265C08K2003/3045C09D5/002C09D175/04C09D177/00E04F13/02C08L63/00C08L77/00C08K9/10C08K3/26C08K3/30C08K3/34

Inventor 赵希娟王炜张剑于钦萍邓宽王满凯于大第郑旗张腾陈夙

Owner CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com