Blood-vein-exposure-proof double-layer suede and manufacturing method thereof

A production method and an uneasy technology, which is applied in special leather manufacturing, leather softening, leather drying, etc., can solve the problems of unrecyclable leftover materials, lower leather usage rate, and unusable leather, so as to shorten the soaking time, reduce tension, and leather plumping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

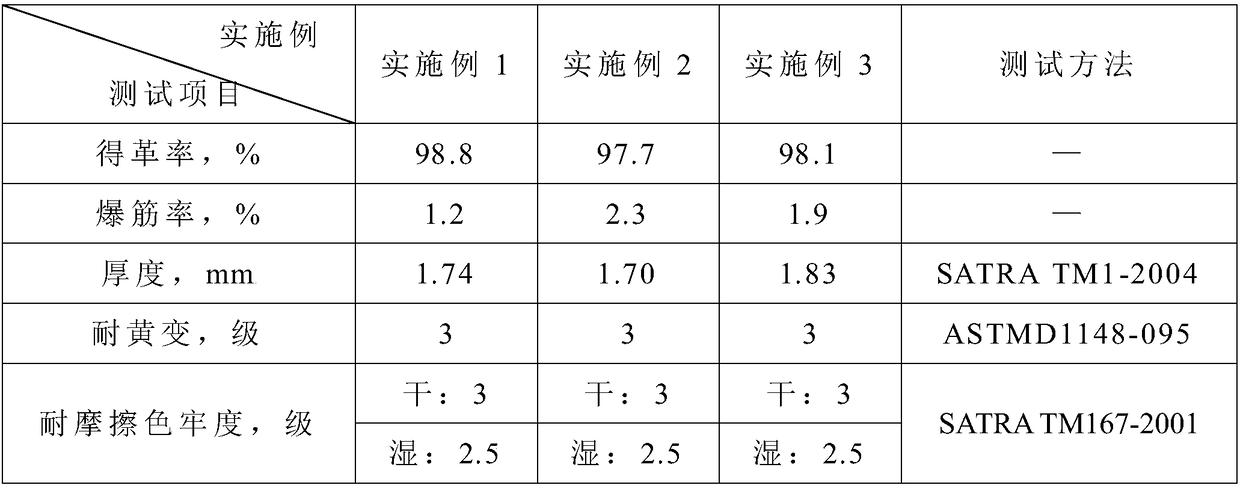

Examples

Embodiment 1

[0032] The manufacture method of non-explosive tendon two-layer suede leather specifically comprises the following steps:

[0033] Step 1, rewetting: take the wet blue hide, weigh it, place it in a drum, and mix 250% of water (water temperature 50°C), 0.5% degreasing agent Eusanpon OC, 0.95 Add 0.08% water-soaking agent Eusapon W and 0.08% water-soaking enzyme Basozym S20 into the drum, adjust the pH to 9.5, and add 1.5% softening enzyme Basozym B10 after running for 60 minutes. Drain to get wet leather;

[0034] Step 2, retanning: add 120% water, 0.5% formic acid, and 2.0% retanning agent (foaming polymer TJ-R6034) to the drum according to the mass of the wet blue hide, run for 30 minutes, and then add 3.0% chromium powder, run for 120 minutes, drain, inject water for washing, and drain again to obtain retanned leather;

[0035] Step 3, neutralization: according to the mass of wet blue hides, add 150% of water, 2.5% of sodium formate, and 1.5% of neutralized tannin Tamol NA...

Embodiment 2

[0042] The manufacture method of non-explosive tendon two-layer suede leather specifically comprises the following steps:

[0043] Step 1, rewetting: take the wet blue hide, weigh it, place it in a drum, and mix 200% water (water temperature 45°C), 0.4% degreasing agent Eusanpon OC, 0.9 Add 0.05% water soaking agent Eusapon W and 0.05% water soaking enzyme Basozym S20 into the drum, adjust the pH to 9, run for 55 minutes, add 1.3% softening enzyme Basozym B10, run for 140 minutes, drain, inject water for washing, and then Drain to get wet leather;

[0044] Step 2, retanning: add 110% water, 0.4% formic acid, and 1.5% retanning agent (foaming polymer TJ-R6034) to the drum according to the mass of the wet blue hide, run for 25 minutes, and then add 2.5% chromium powder, run for 115 minutes, drain, inject water for washing, and then drain to obtain retanned leather;

[0045] Step 3, neutralization: according to the mass of wet blue hides, add 140% of water, 2.2% of sodium forma...

Embodiment 3

[0052] The manufacture method of non-explosive tendon two-layer suede leather specifically comprises the following steps:

[0053] Step 1, rewetting: take the wet blue hide, weigh it, place it in a drum, and mix 300% water (water temperature 50°C), 0.6% degreaser Eusanpon OC, 1.0% according to the mass of the wet blue hide Add 0.1% water-soaking agent Eusapon W and 0.1% water-soaking enzyme Basozym S20 into the drum, adjust the pH to 10, and add 1.7% softening enzyme Basozym B10 after running for 65 minutes. Drain to get wet leather;

[0054] Step 2, retanning: add 130% water, 0.6% formic acid, and 2.5% retanning agent (foaming polymer TJ-R6034) to the drum according to the mass of the wet blue hide, run for 35 minutes, and then add 3.5% chromium powder, run for 125 minutes, drain, inject water for washing, and drain again to obtain retanned leather;

[0055] Step 3, neutralization: according to the mass of wet blue hide, add 160% water, 2.8% sodium formate, 2% neutralized t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com