Novel incubation-free spheroidizing agent

A spheroidizing agent and a new type of technology, applied in the field of casting, can solve the problems of infringing on the health of workers, increasing the labor intensity of workers, polluting the environment by smoke and dust, and achieving the effects of low cost, few steps, and good moisture-proof performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

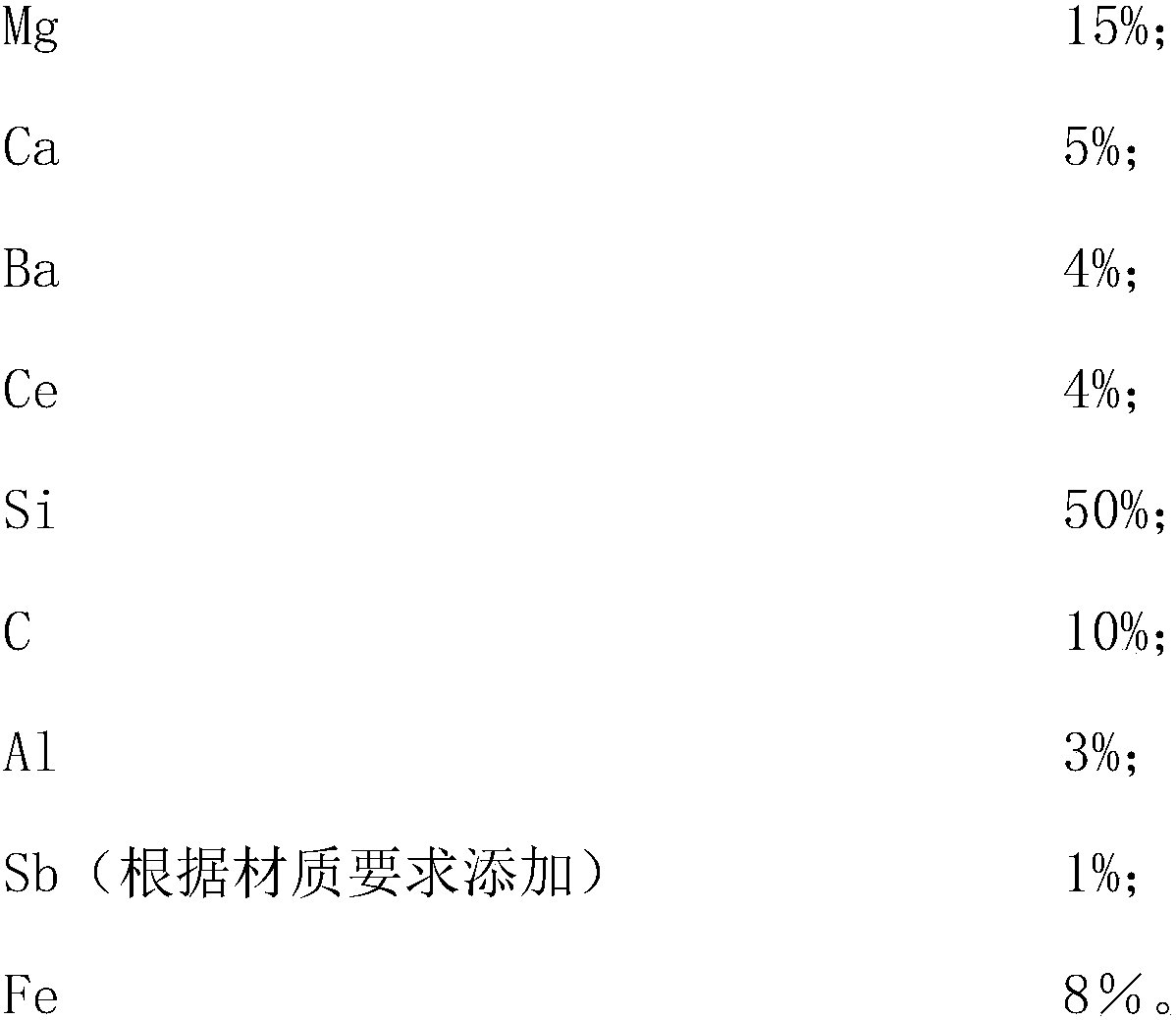

[0024] Preferred embodiment 1, each element content of nodulizer is (percentage by weight),

[0025]

[0026] Among them, the spheroidizing ability of Ce is second only to Mg and has the characteristics of re-spheroidizing function, and an appropriate amount of Ce is added. Use aluminum to increase the ferrite content, add an appropriate amount of aluminum; use the characteristics of ca as a strong spheroidizing element, add an appropriate amount of ca; use calcium and barium to add together with the characteristics of ferrite content increases with the increase of barium content , and use the long-acting properties of barium to increase a certain amount of barium, eliminate the decline of gestation, and add an appropriate amount of barium.

Embodiment 2

[0028] The content of each element of the nodulizer is (weight percent),

[0029]

[0030]

[0031] In this way, using lanthanum has a greater effect on promoting the increase of cast ferrite content than cerium, adding a certain amount of lanthanum, and to a certain extent, adding a certain amount of La can significantly reduce the micro-shrinkage tendency of ductile iron. Use aluminum to increase the ferrite content, add an appropriate amount of aluminum; use the characteristics of ca as a strong spheroidizing element, add an appropriate amount of ca; use calcium and barium to add together with the characteristics of ferrite content increases with the increase of barium content , and use the long-acting properties of barium to increase a certain amount of barium, eliminate the decline of gestation, and add an appropriate amount of barium. The use of recarburizer and silicon carbide can provide the nucleation core required for graphite crystallization, adding an appropr...

Embodiment 3

[0033] The content of each element of the nodulizer is (weight percent),

[0034]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com