Flexible piezoelectric nanofiber membrane and preparation method and application thereof

A nanofiber membrane, flexible piezoelectric technology, applied in the field of piezoelectricity, can solve the problems of not being able to meet the use requirements of piezoelectric sensors, poor electrical performance output, etc. low cost to manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

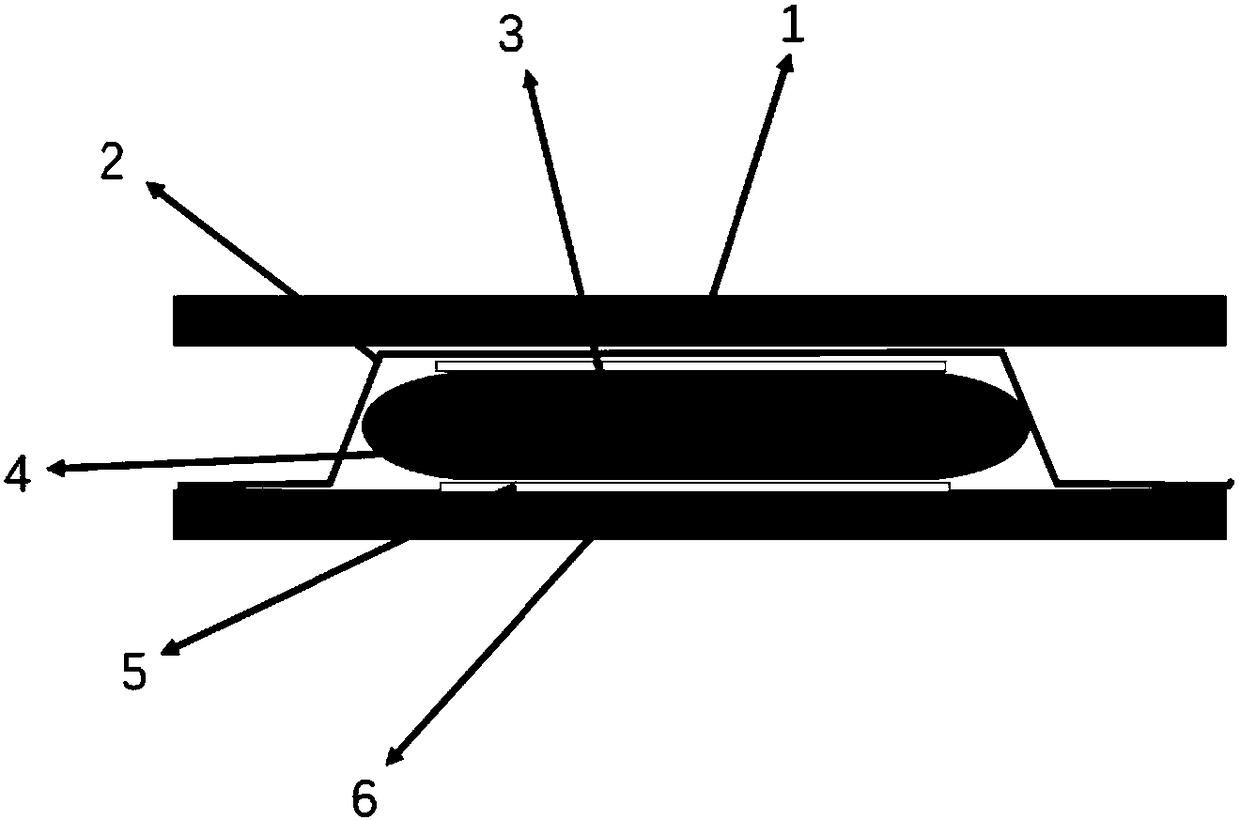

[0023] A method for preparing a flexible piezoelectric nanofiber membrane provided by an embodiment of the present invention comprises the following steps:

[0024] S1. After mixing and stirring the dimethyl sulfoxide solution of zinc acetate and the ethanol solution of tetramethylammonium hydroxide in sequence, add ethyl acetate to precipitate nanoparticles, add ethanolamine to stabilize the nanoparticles, and then centrifuge to separate ZnO nanoparticles, and dry the ZnO nanoparticles.

[0025] Further, in the process of preparing ZnO nanoparticles, the dosage ratio of zinc acetate and tetramethylammonium hydroxide is 3mmol:5.5mmol, and the dosage of ethyl acetate is 40mL. It should be noted that the reason why ethyl acetate is added and its amount is limited is to ensure that the expected target ZnO nanoparticles can be obtained, so that the final particle size of ZnO nanoparticles can also meet the expected requirements.

[0026] Further, in the embodiment of the present ...

Embodiment 1

[0044] This embodiment provides a method for preparing a flexible piezoelectric nanofiber membrane, the preparation process comprising:

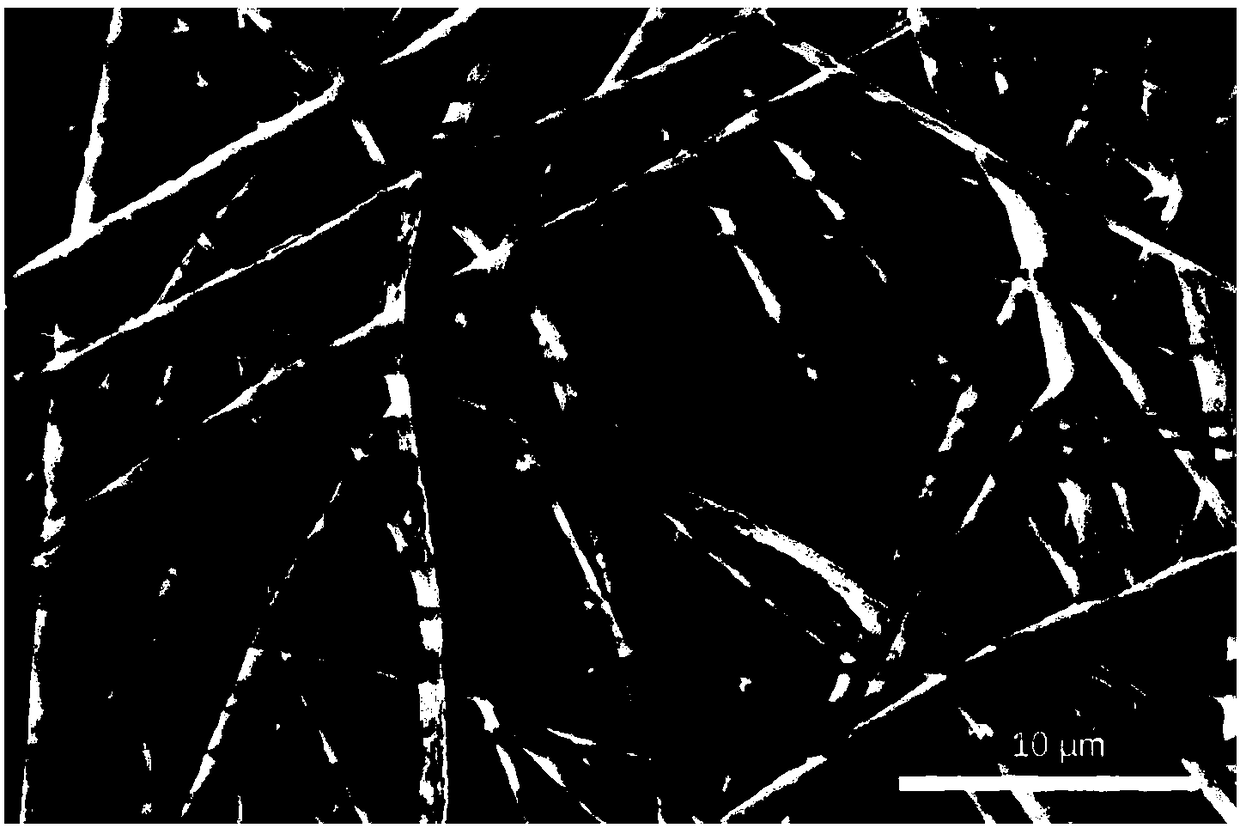

[0045] Preparation of ZnO nanoparticles: Mix a solution of zinc acetate (3mmol) in dimethyl sulfoxide (DMSO 30mL) with a solution of tetramethylammonium hydroxide (TMAH 5.5mmol) in ethanol (10mL), stir for 24h, then add ethyl acetate (40mL) will precipitate ZnO nanoparticles, add ethanolamine (160μL) to stabilize the nanoparticles, separate the ZnO nanoparticles with a centrifuge (10000 rpm), and dry them in an oven at 40°C to obtain 30nm microspheres particles.

[0046] Configuration of PVDF solution: Dissolve PVDF in a mixed solution of acetone and dimethylacetamide (DMAc), wherein the volume ratio of acetone and DMAc is 5:7, and the mass fraction of PVDF is 25%.

[0047] Preparation of ZnO / PVDF mixed solution: the above-prepared ZnO nanoparticles were first dissolved in acetone and DMAc solution, then the above-prepared PVDF solution was...

Embodiment 2

[0052] This embodiment provides a method for preparing a flexible piezoelectric nanofiber membrane, the preparation process comprising:

[0053] Preparation of ZnO nanoparticles: Mix a solution of zinc acetate (3mmol) in dimethyl sulfoxide (DMSO 30mL) with a solution of tetramethylammonium hydroxide (TMAH 5.5mmol) in ethanol (10mL), stir for 24h, then add ethyl acetate (40mL) will precipitate ZnO nanoparticles, add ethanolamine (160μL) to stabilize the nanoparticles, separate the ZnO nanoparticles with a centrifuge (10010 rpm), and dry them in an oven at 40°C to obtain 32nm microspheres particles.

[0054] Configuration of PVDF solution: Dissolve PVDF in a mixed solution of acetone and dimethylacetamide (DMAc), wherein the volume ratio of acetone and DMAc is 5:7, and the mass fraction of PVDF is 28%.

[0055] Preparation of ZnO / PVDF mixed solution: the above-prepared ZnO nanoparticles were first dissolved in a solution of acetone and DMAc, then the above-prepared PVDF solutio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com