Solid acid pretreatment method for biomass material

A technology for pretreatment of biomass and solid acid, applied in fiber raw material processing, textile and papermaking, fermentation, etc., can solve the problems of human, equipment injury, insignificant effect, long processing time, etc., and meet the requirements of equipment and personnel. , the effect of small inhibition and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Include the following steps:

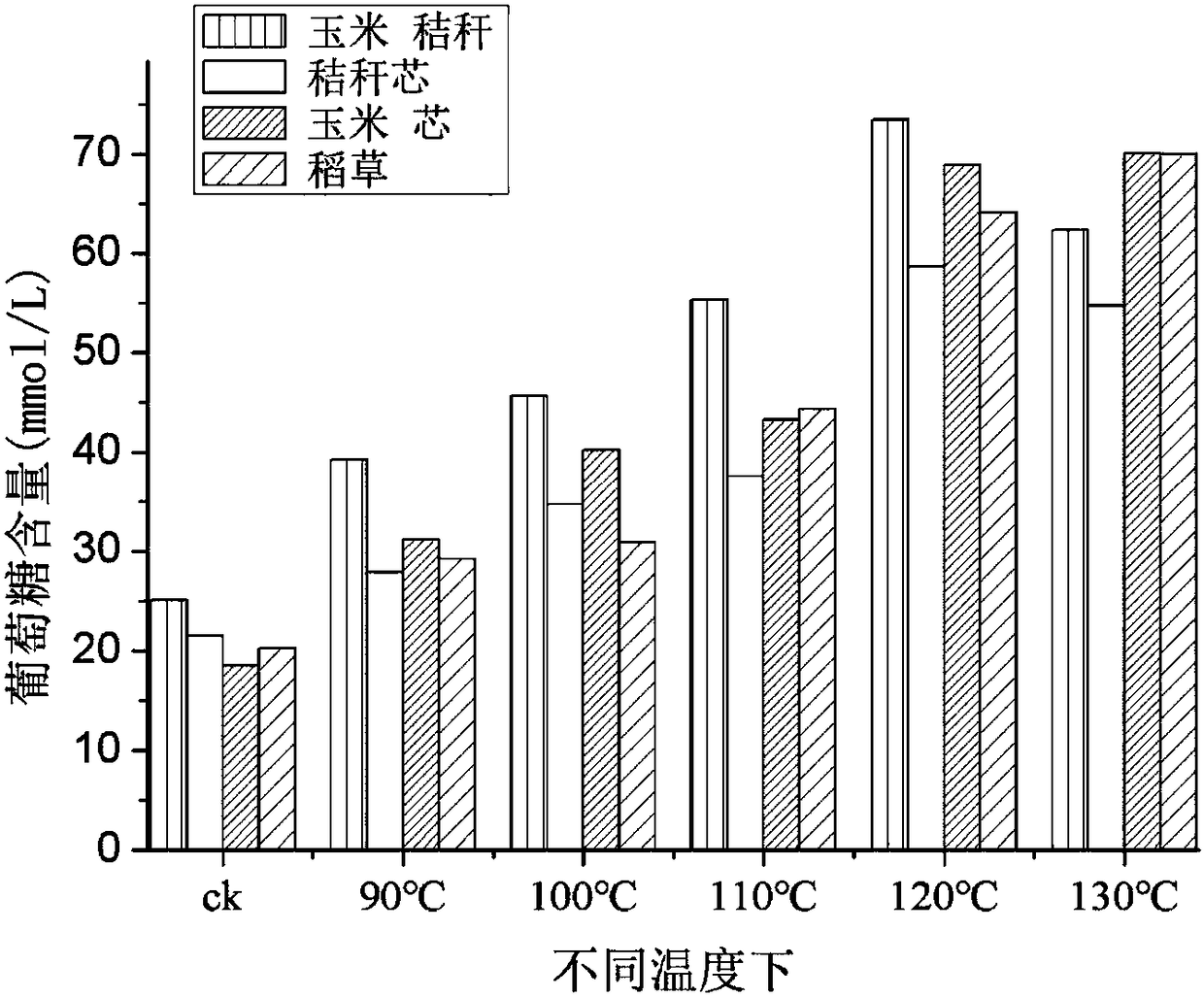

[0021] (1) Collect corn stalks, straw, corn cobs or straw cobs, dry them at 105°C, and crush them to 40 meshes;

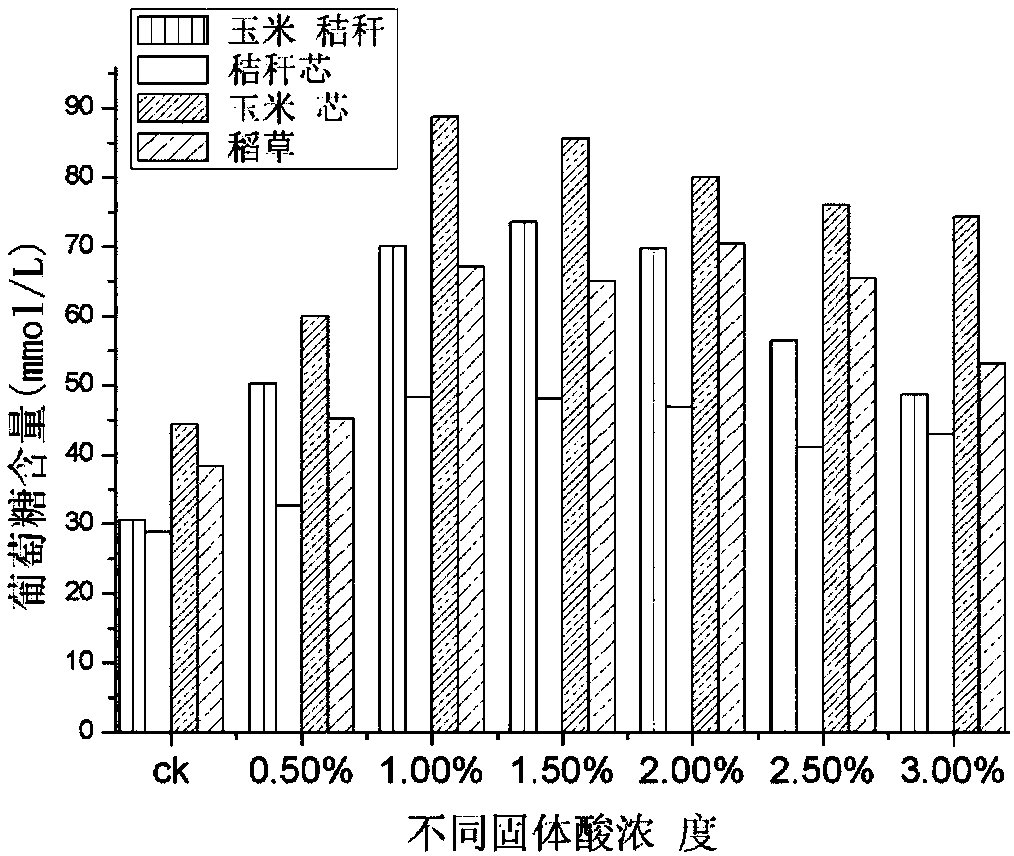

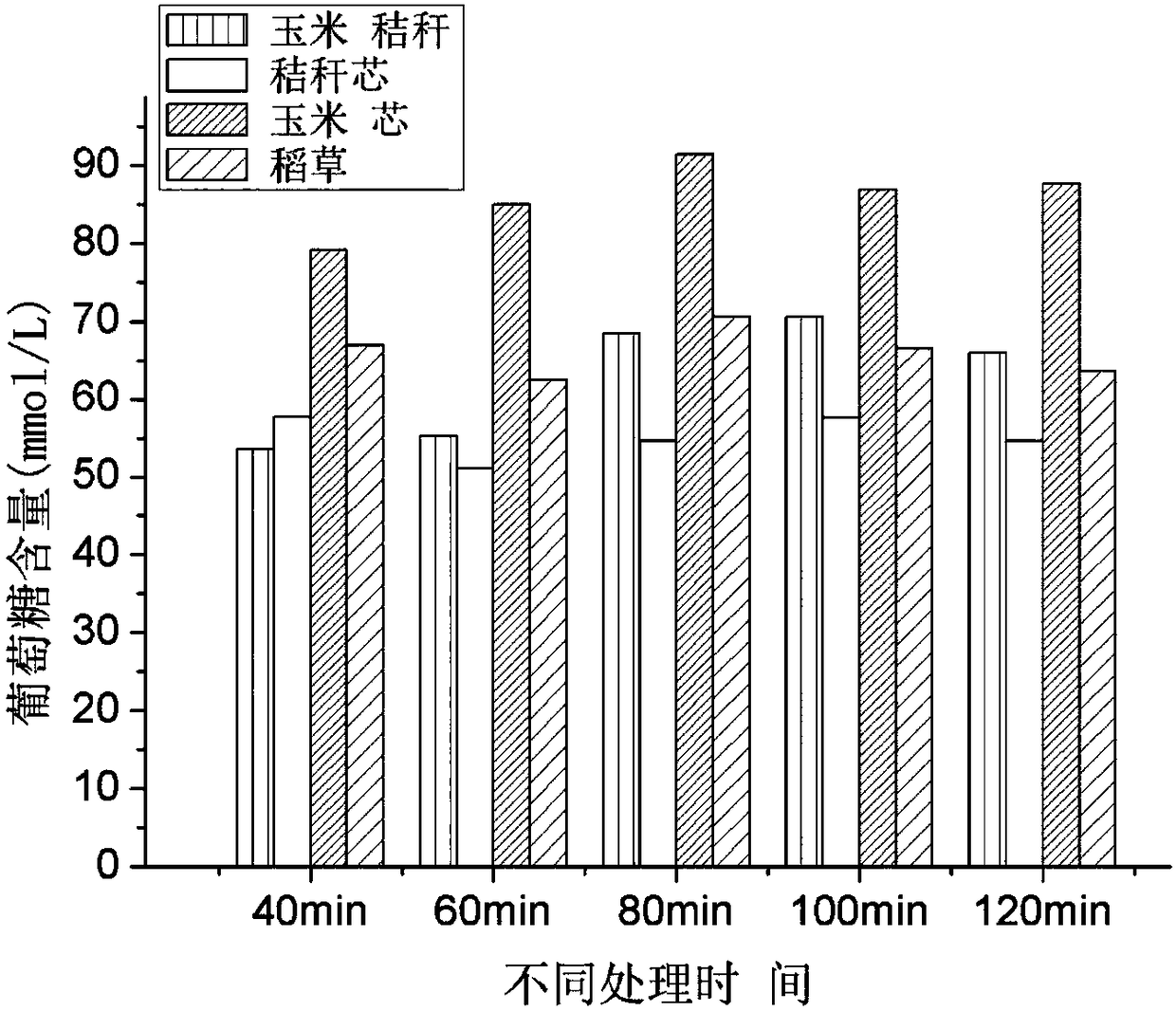

[0022] (2) 10 times the volume of solid acid was added, the concentration of the solid acid was 0.5%, the time was 20 minutes, and the temperature was 90°C.

Embodiment 2

[0024] Include the following steps:

[0025] (1) Collect corn stalks, straw, corncobs or straw cobs, dry them at 105°C, and crush them to 60 meshes;

[0026] (2) 16 times the volume of solid acid was added, the concentration of the solid acid was 2%, the time was 80 minutes, and the temperature was 110°C.

Embodiment 3

[0028] Include the following steps:

[0029] (1) Collect corn stalks, straw, corn cobs or straw cobs, dry them at 105°C, and crush them to 80 meshes;

[0030] (2) 25 times the volume of solid acid was added, the concentration of the solid acid was 3%, the time was 120min, and the temperature was 140°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com