Graphene oxide/copper oxide composite powder, preparation method thereof and microcosmic laminated structure graphene/copper composite material preparation method

A composite powder and copper oxide technology, applied in the field of powder metallurgy, can solve problems such as complex process, difficulty in large-scale actual production, and difficulty in obtaining composite material blocks, and achieve simple equipment and operation, easy mass production, high intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

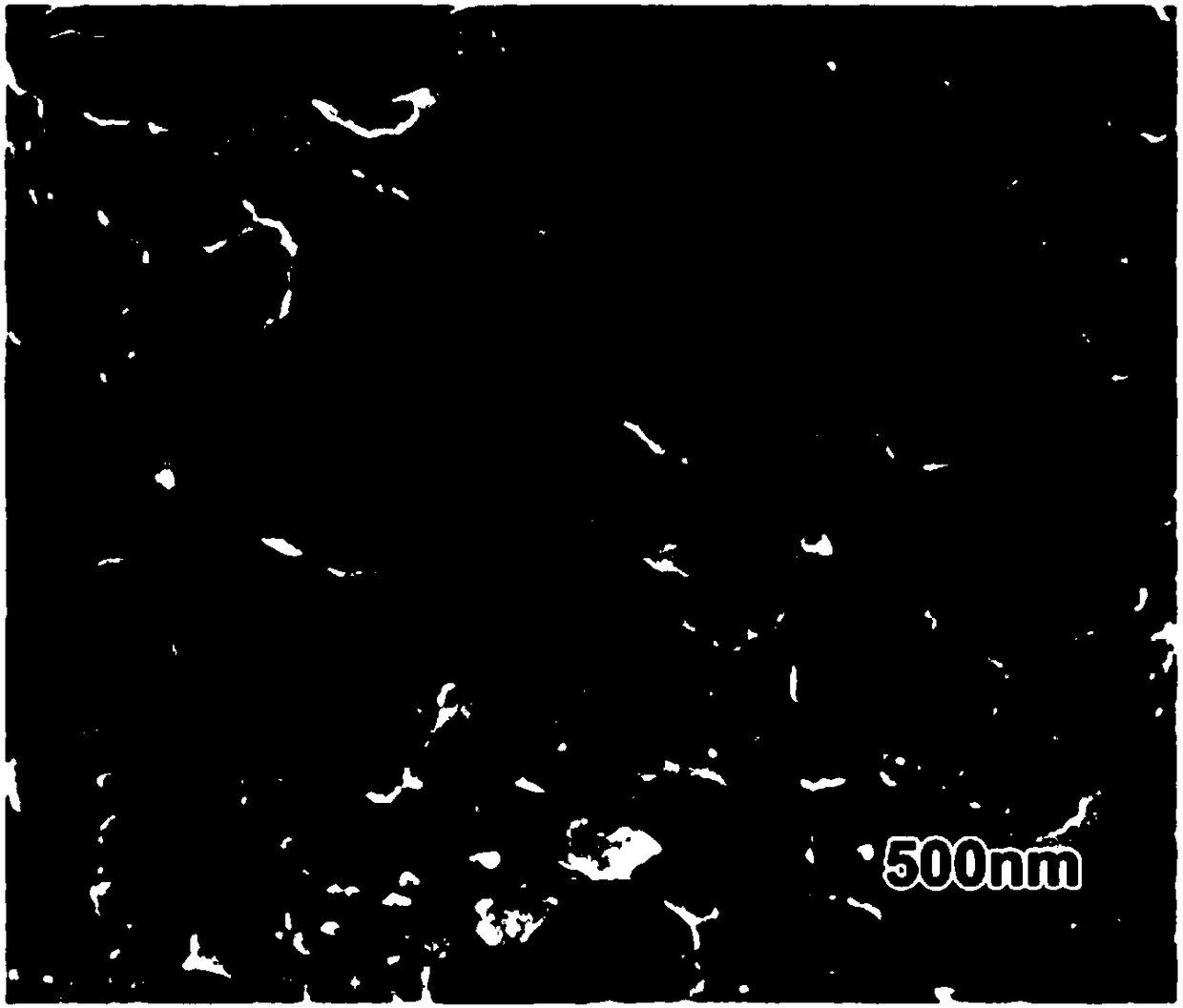

[0037] Embodiment 1: The graphene oxide / copper oxide composite powder of this embodiment is carried out according to the following steps: copper acetate is dissolved in deionized water to obtain a copper salt solution with a concentration of 0.29mol / L, and the copper salt The solution and the graphene oxide solution with a concentration of 1mg / ml were mixed according to the mass ratio of graphene oxide and copper in the copper salt of 0.0066:100 and stirred for 30min; The sodium solution was adjusted to a pH value of 13.6, washed with deionized water until neutral, and dried at 110° C. to obtain a graphene oxide / copper oxide composite powder (microscopic layered structure).

[0038] The method for preparing a microscopic layered structure graphene / copper composite material using the graphene oxide / copper oxide composite powder obtained in this embodiment is completed by the following steps:

[0039] Step 1. The graphene oxide / copper oxide composite powder is subjected to reduc...

specific Embodiment approach 2

[0045] Specific embodiment two: the graphene oxide / copper oxide composite powder of the present embodiment is carried out according to the following steps: copper acetate is dissolved in deionized water to obtain a copper salt solution with a concentration of 0.28mol / L, and the copper salt The solution and the graphene oxide solution with a concentration of 1mg / ml were mixed according to the mass ratio of graphene oxide and copper in the copper salt of 0.0136:100 and stirred for 30min; The sodium solution was adjusted to a pH value of 13.6, washed with deionized water until neutral, and dried at 110° C. to obtain a graphene oxide / copper oxide composite powder (microscopic layered structure).

[0046] The method for preparing a microscopic layered structure graphene / copper composite material using the graphene oxide / copper oxide composite powder obtained in this embodiment is completed by the following steps:

[0047] Step 1. The graphene oxide / copper oxide composite powder is ...

specific Embodiment approach 3

[0049] Specific embodiment three: the graphene oxide / copper oxide composite powder of the present embodiment is carried out according to the following steps: copper acetate is dissolved in deionized water to obtain a copper salt solution with a concentration of 0.29mol / L, and the copper salt The solution and the graphene oxide solution with a concentration of 1mg / ml were mixed according to the mass ratio of graphene oxide and copper in the copper salt of 0.0066:100 and stirred for 30min; The sodium solution was adjusted to a pH value of 13.6, washed with deionized water until neutral, and dried at 110° C. to obtain a graphene oxide / copper oxide composite powder (microscopic layered structure).

[0050] The method for preparing a microscopic layered structure graphene / copper composite material using the graphene oxide / copper oxide composite powder obtained in this embodiment is completed by the following steps:

[0051] Step 1. The graphene oxide / copper oxide composite powder i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

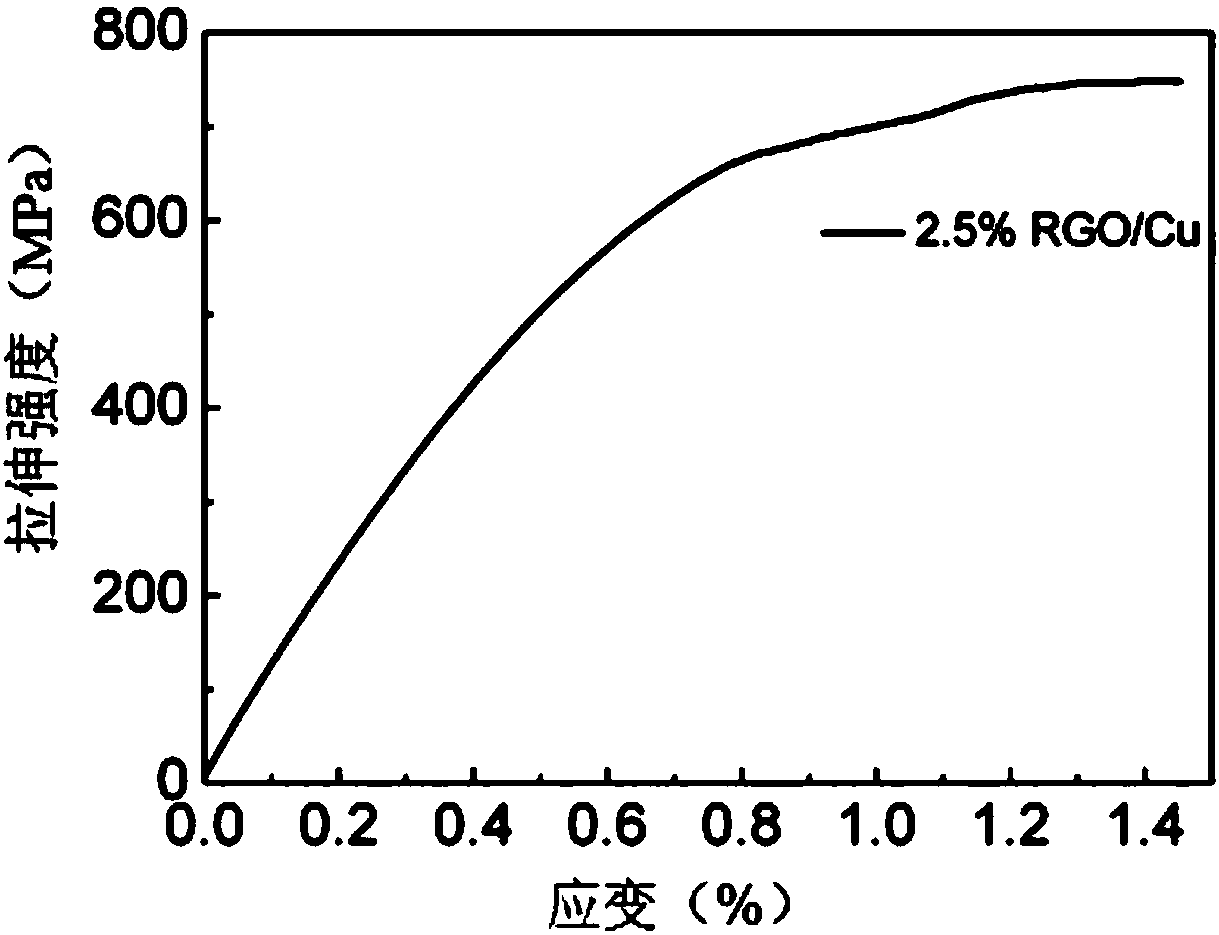

| Tensile strength | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com