Phosphonic acid-based block polymer, and preparation method and application thereof

一种膦酸基嵌段、酸基嵌段的技术,应用在膦酸基嵌段聚合物领域,能够解决坍落度损失大、混凝土初始分散效率低、体系粘度高等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

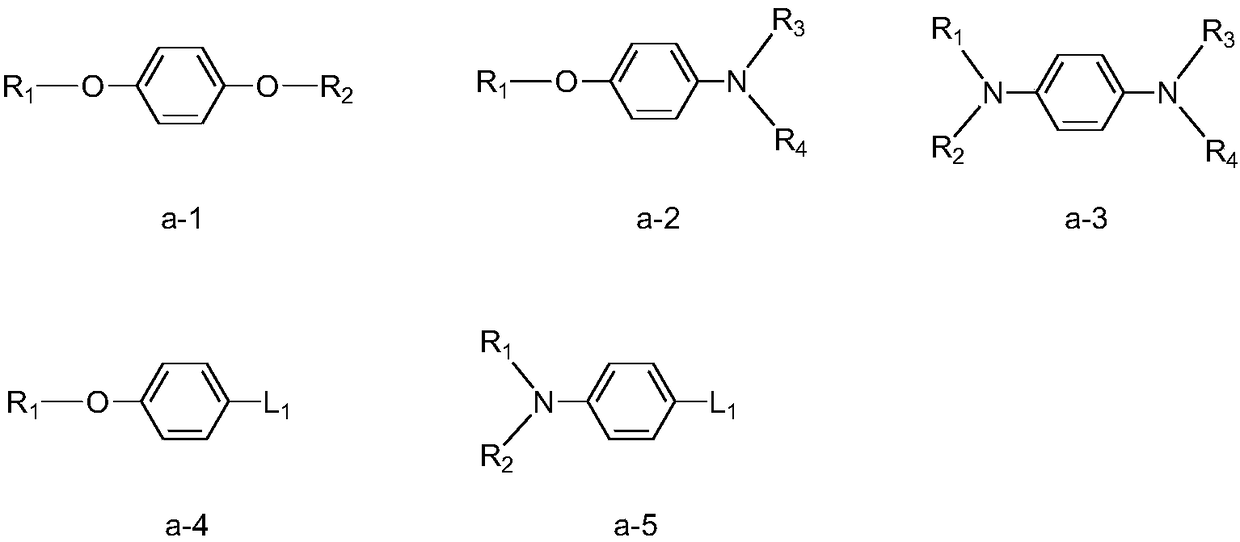

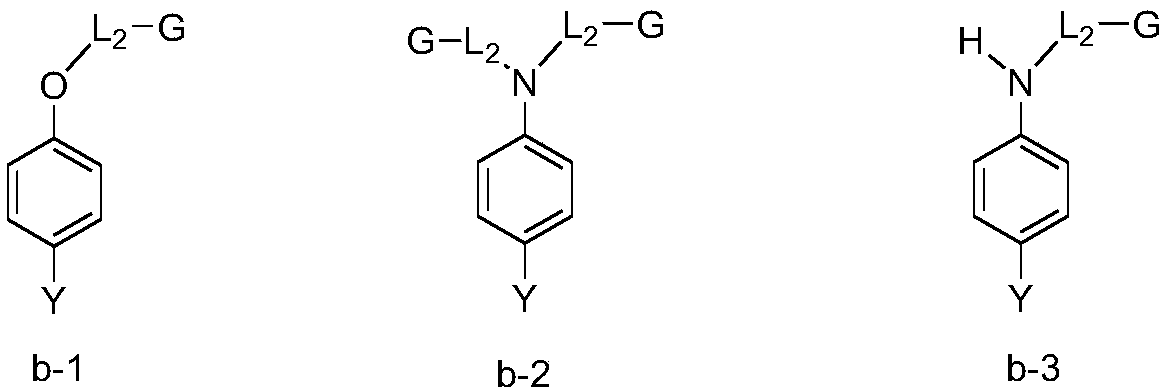

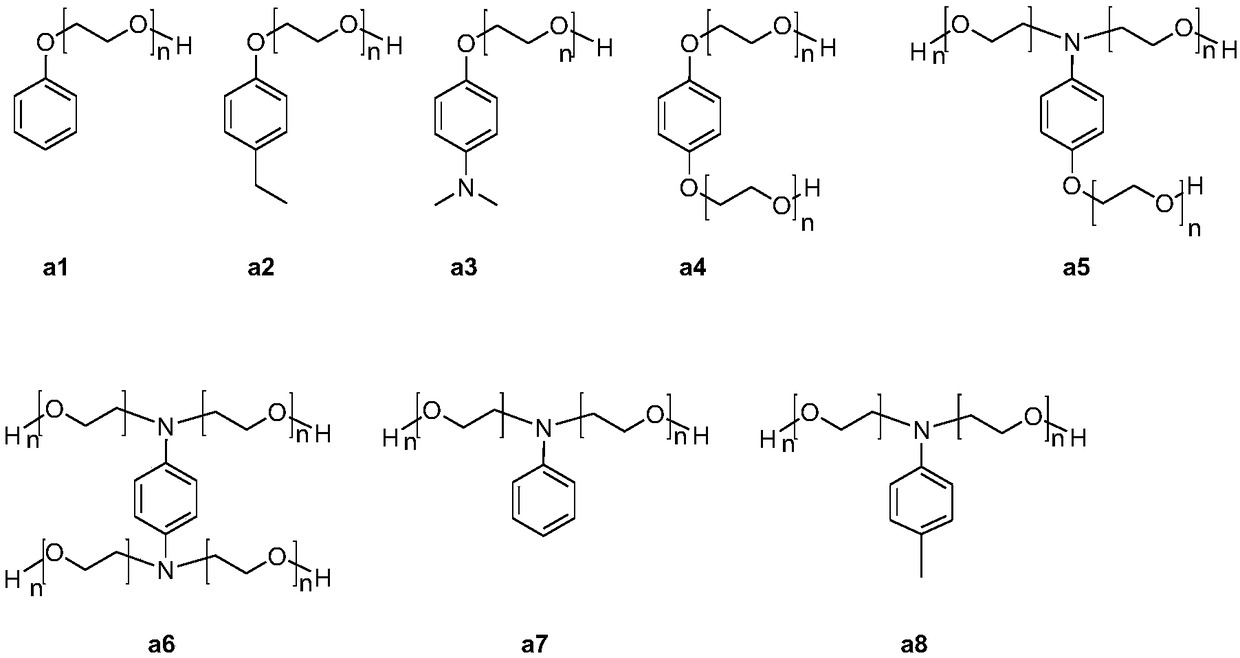

Method used

Image

Examples

preparation example Construction

[0107] (3) Preparation of phosphonic acid-based block polymers

[0108] In a 1000ml four-neck flask equipped with electric mechanical stirring, add about 145 g of the solution containing ether type segment A and about 81 g of the solution containing phosphonic acid group segment B prepared above (wherein phosphonic acid group segment B / ether type segment The molar ratio of A is 4.8), concentrated sulfuric acid (catalyst) 0.06mol (20% of the molar weight of (polyether monomer a+phosphonic acid group monomer b)) and an appropriate amount of reaction solvent water 10g, stirred for 10min until uniformly mixed, Slowly add 0.10 mol of formaldehyde (33% of the molar weight of (polyether monomer a + phosphonic acid monomer b)) dropwise for about 30 minutes, then raise the temperature to 108°C, react for 2.5 hours, cool down, and add liquid Adjust the PH value to about 4.0 with alkali, add water to adjust the solid content to about 30%, and obtain a colorless or light yellow solution. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com