HDPE/FF antibacterial composite material with ZnO-SiO2 and preparation method thereof

A composite material, zno-sio2 technology, applied in the direction of enzyme/microorganism biochemical treatment, biochemical fiber treatment, textile and papermaking, etc. problem, to achieve the effect of easy absorption, large specific surface area, and improved antibacterial properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A kind of added ZnO-SiO 2 The HDPE / FF composite material, its formula is:

[0041]

[0042] A kind of added ZnO-SiO 2 The preparation method of HDPE / FF composite material, the step of its preparation method is:

[0043] (1) Prepare 90wt% ethanol aqueous solution, pour KH570 into the ethanol solution, stir magnetically for 1 hour, and vibrate ultrasonically for 2 hours. Soak FF in ethanol for 1 hour, heat in a water bath at 60-80°C and stir constantly, add the treated KH570 solution drop by drop into the ethanol slurry containing FF, stir for 2 hours, take out the FF in the slurry, Dry in an oven at °C for later use.

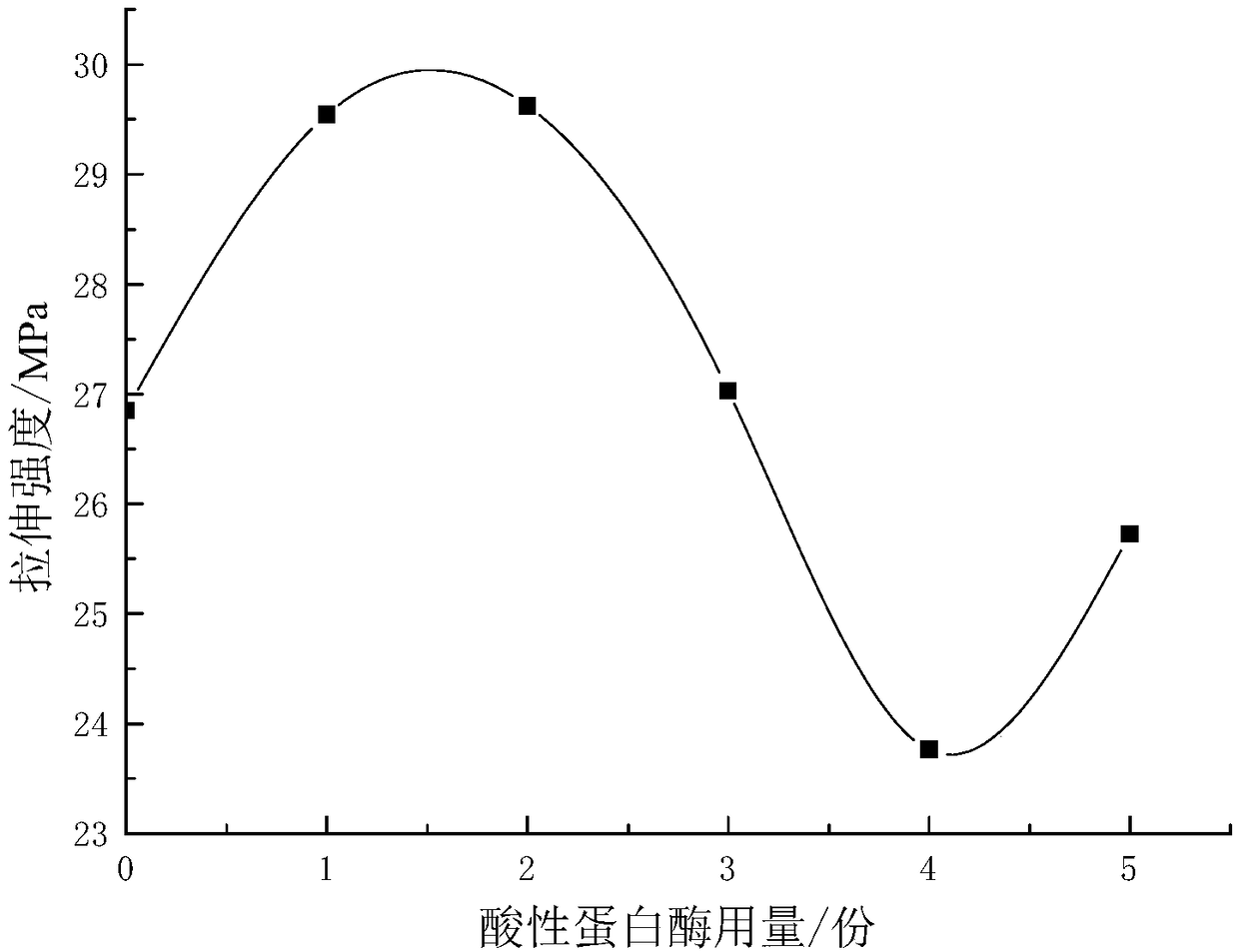

[0044] (2) Put the acidic protease into a mixed solution of 5ml / l hydrogen peroxide and absolute ethanol, adjust the pH to 4-6 with acid, stir magnetically for 30-50min at a temperature of 60-80°C, add FF and stir evenly , ultrasonically cleaned for 40-60 min, and dried to obtain the product.

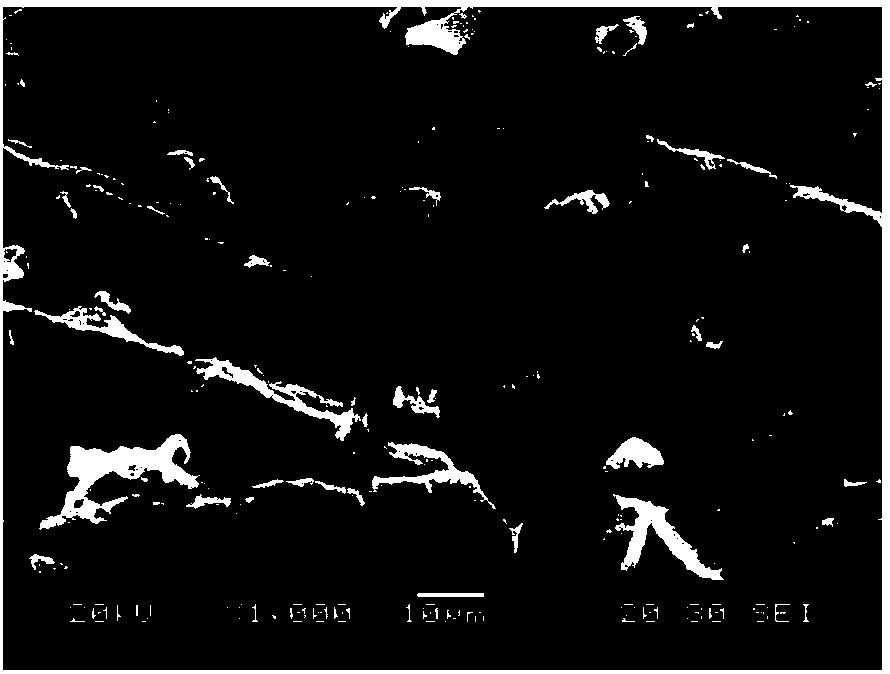

[0045] (3) Coupling treated FF and HDPE with ZnO-SiO a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com