Preparation method of super-hydrophobic super-oleophobic polymer nano-coating

A super-hydrophobic, super-oleophobic, and nano-coating technology, which is applied in coatings and other directions, can solve problems such as high equipment requirements, high energy consumption, and high pyrolysis temperature, and achieve excellent performance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

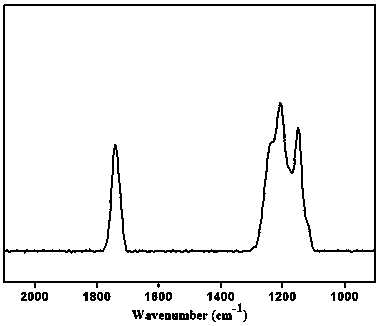

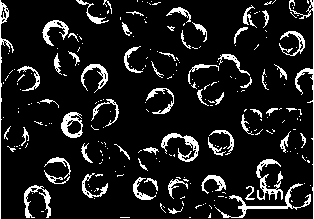

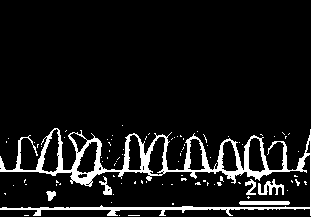

[0029] Place the pretreated glass sheet as the base material on the sample stage in the cavity, and fix the base so that it is fully in contact with the bottom surface. Turn on the mechanical pump to evacuate the chamber to a vacuum state. Heating initiator perfluorobutylsulfonyl fluoride, reactive monomer 1H,1H,2H,2H-perfluorodecyl acrylate, crosslinker 2,4,6-trivinyl-2,4,6-trimethyl Cyclotrisiloxane; the flow rates of monomer and crosslinking agent are 0.1 sccm and 10 sccm respectively; the initiator flow rate is 0.5 sccm; the chamber pressure is 100 mTorr; the temperature of the hot wire is 150 °C; The distance between the warm-up source and the substrate material is 1 cm; the deposition thickness is 100 nm; the deposition time is 20 min; and the deposition rate is 5 nm / min. Such as figure 1 As shown, this figure is the Fourier transform infrared spectrogram obtained by the processing conditions of Example 1 of the polymer nano-coating film. It can be seen from this figur...

Embodiment 2

[0031] The base material in embodiment 1 is changed into cotton cloth; Monomer flow and linking agent flow are changed into 5sccm and 5sccm; Initiator uses benzoyl peroxide tert-butyl peroxide instead, and initiator flow is 5sccm; Other conditions are constant, The deposition thickness is 100 nm; the deposition time is 15 min; the deposition speed is 6.7 nm / min.

Embodiment 3

[0033] In Example 1, the substrate material was changed to PDMS membrane; the monomer flow rate and the crosslinking agent flow rate were changed to 10 sccm and 0.1 sccm; the initiator was changed to perfluorooctanesulfonyl fluoride, and the initiator flow rate was 10 sccm. Other conditions remain unchanged, the deposition thickness is 100nm; the deposition time is 10min; the deposition rate is 10nm / min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com