Shear thickening gel/three-dimensional woven energy-absorbing material and preparation method thereof

A technology of energy-absorbing materials and thickening gels, applied in chemical instruments and methods, lamination, layered products, etc., can solve problems such as easy sedimentation of shear-thickening liquids, affecting the energy-absorbing effect of materials, and difficulties in implementation. Achieve the effects of flexibility, lightness, increased application range, and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

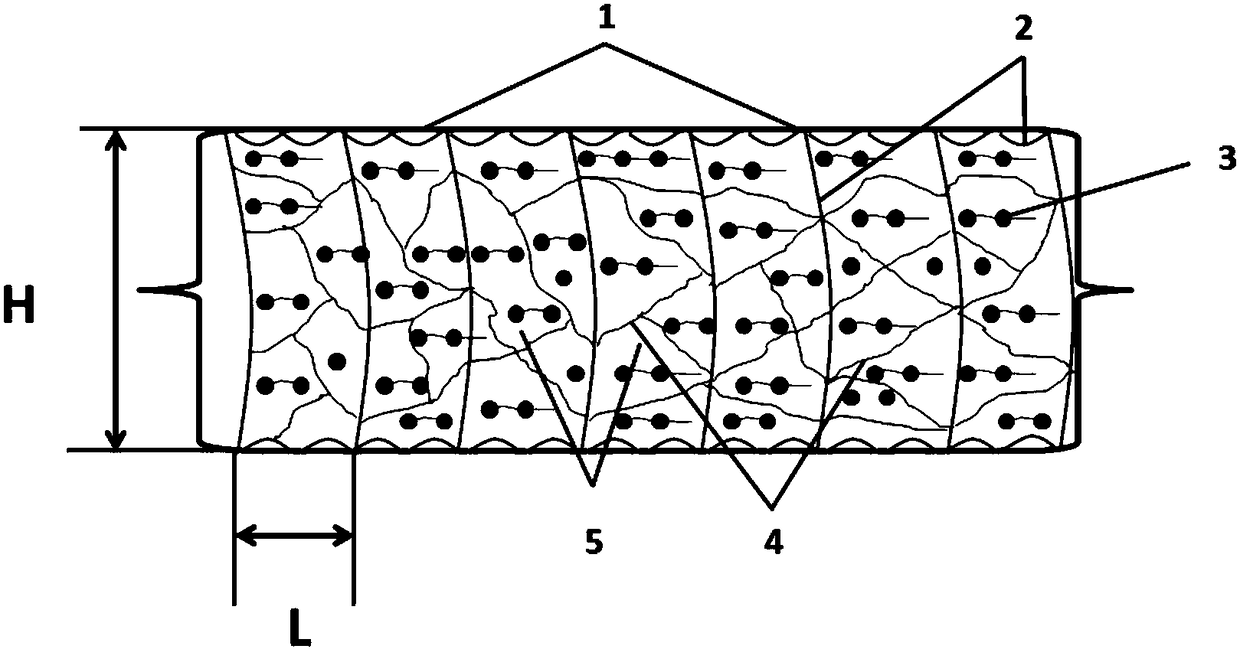

[0034] Embodiment 1 (acrylate network shear thickening gel)

[0035] Use high-performance three-dimensional braided fibers, such as polyester, ultra-high molecular weight polyethylene fibers, polyaramid fibers or PBO fibers, etc., and use 3D weaving technology to weave high-performance sandwich materials; cut the three-dimensional braided packaging materials according to the designed shape , use adhesive to cold-bond the three-dimensional woven cloth with the upper and lower layers of outer packaging materials, seal on all sides, leave only one pouring port, then take acrylic acid, β-hydroxyethyl acrylate, STF liquid, initiator mixture (wherein the initiator accounts for the polymer The network weight ratio is 1.5%, in STF liquid) at 20°C, mechanically stir to make a mixture; pour the mixture into the three-dimensional braided sandwich composite material, and then place it at 40°C for curing. After it is completely cured, the pouring port Cold-bonded and sealed to prepare shea...

Embodiment 2

[0037] Embodiment 2 (silicone rubber network shear thickening gel)

[0038] Use high-performance three-dimensional braided fibers, such as polyester, ultra-high molecular weight polyethylene fibers, polyaramid fibers or PBO fibers, etc., and use 3D weaving technology to weave high-performance sandwich materials; cut the three-dimensional braided packaging materials according to the designed shape , use adhesive to cold-bond the three-dimensional woven cloth with the upper and lower layers of outer packaging materials, seal on all sides, leaving only one pouring port, and then mix the shear thickening liquid with vinyl silicone oil or vinyl silicone resin, hydrogen-containing silicone oil or hydrogen-containing The hydrosilylation type liquid silicone rubber composition composed of silicone resin, platinum catalyst and hydrophobic white carbon black filler is mechanically stirred and mixed, and the content of platinum catalyst is 0.2% to 0.5% of the whole system weight. Then pl...

Embodiment 3

[0045] Mix 107 glue with ethyl orthosilicate methyltriethoxysilane and STF liquid. After uniformity, add dibutyltin dilaurate initiator, and pour the mixture into the fitted three-dimensional sandwich structure cavity. solidify. The dosage of the initiator dibutyltin dilaurate is between 1% and 3% of the total weight of the 107 glue and ethyl orthosilicate methyltriethoxysilane. All the other are identical with embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com