Fair-faced concrete composite admixture and fair-faced concrete

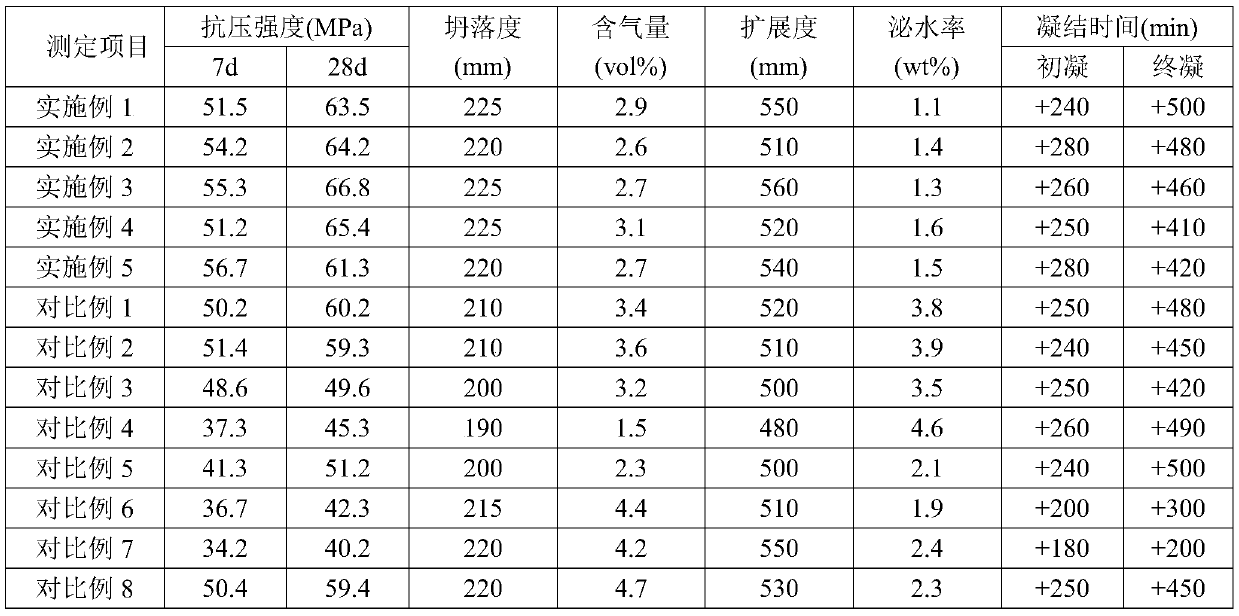

A technology of fair-faced concrete and composite admixture, which is applied in the field of concrete materials, can solve the problems of short initial setting and final setting time of concrete, increase of concrete bleeding rate, affecting the smoothness and flatness of fair-faced concrete surface, etc., and prolongs initial setting. The time interval between setting and final setting, the effect of improving smoothness and flatness, and the long interval between initial setting and final setting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

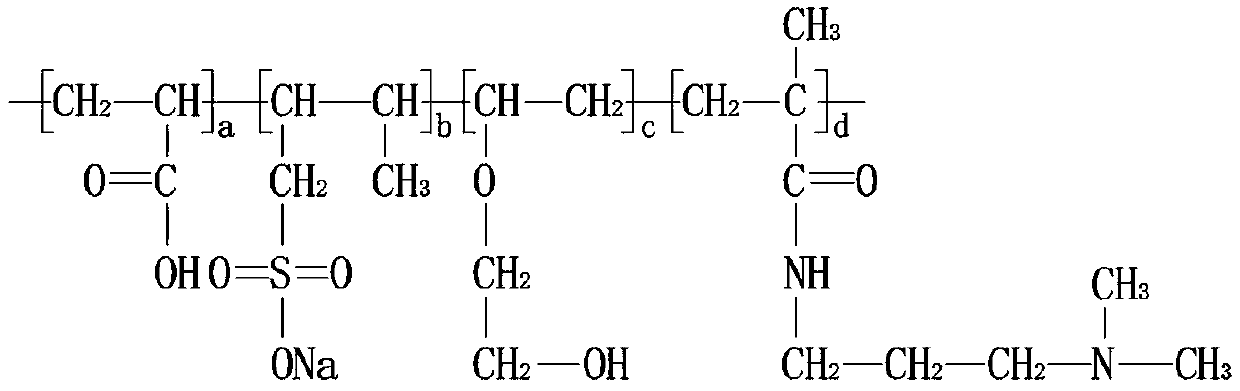

[0027] Preparation of polycarboxylate copolymer: Weigh 250Kg of water and place it in a reaction kettle, add 32Kg of sodium methacrylate sulfonate monomer, 30Kg of vinyl glycol ether monomer, and 17Kg of dimethylaminopropyl methacrylic acid in sequence Amide monomer, and add 5Kg ammonium persulfate initiator, mix well, heat up to 60°C, add 29Kg acrylic acid monomer, continue to heat up to 90°C, react for 4 hours, cool, adjust the pH value to 6~ with sodium hydroxide 7. Obtain the polycarboxylate copolymer solution, purify and dry with ethanol to obtain a polycarboxylate copolymer with an average molecular weight of 500,000.

[0028] Preparation of clear-water concrete composite admixture: 80Kg polycarboxylate copolymer, 5Kg fatty alcohol ether sodium sulfate, 2Kg fatty acid diethanolamide, 10Kg nonahydrate sodium metasilicate, 15Kg citric acid-disodium hydrogen phosphate, 10Kg gluconic acid Sodium, 3.5Kg of polyoxyethylene polyoxypropanolamine ether, 22Kg of tetramethylurea, 3...

Embodiment 2

[0031] Preparation of polycarboxylate copolymer: Weigh 250Kg of water and place it in a reaction kettle, add 16Kg of sodium methacrylate sulfonate monomer, 35Kg of vinyl glycol ether monomer, and 22Kg of dimethylaminopropyl methacrylic acid in sequence Amide monomer, and add 5Kg ammonium persulfate initiator, mix well, heat up to 60°C, add 31Kg acrylic acid monomer, continue to heat up to 90°C, react for 4 hours, cool, adjust the pH value to 6~ with sodium hydroxide 7. Obtain the polycarboxylate copolymer solution, purify and dry with ethanol to obtain a polycarboxylate copolymer with an average molecular weight of 600,000.

[0032] Preparation of fair-faced concrete composite admixture: 83Kg polycarboxylate copolymer, 6Kg sodium alkylbenzene sulfonate, 3Kg sucrose fatty acid ester, 4Kg sodium silicate, 12Kg disodium hydrogen phosphate-sodium dihydrogen phosphate, 12Kg sodium gluconate , 5Kg polyoxyethylene polyoxypropanolamine ether, 20Kg tetramethylurea, 34Kg polyethylene gl...

Embodiment 3

[0035] Preparation of polycarboxylate copolymer: Weigh 250Kg of water and place it in a reaction kettle, add 20Kg of sodium methacrylate sulfonate monomer, 18Kg of vinyl glycol ether monomer, and 25Kg of dimethylaminopropyl methacrylic acid in sequence Amide monomer, and add 5Kg ammonium persulfate initiator, mix well, heat up to 60°C, add 46Kg acrylic acid monomer, continue to heat up to 90°C, react for 4 hours, cool, adjust the pH value to 6~ with sodium hydroxide 7. Obtain the polycarboxylate copolymer solution, purify and dry with ethanol to obtain a polycarboxylate copolymer with an average molecular weight of 600,000.

[0036] Preparation of clear-water concrete composite admixture: 86Kg polycarboxylate copolymer, 7Kg polyacrylamide, 4Kg alkylphenol polyoxyethylene ether, 5.5Kg sodium aluminosilicate, 13Kg acetic acid-ammonium acetate, 5Kg sodium gluconate, 2Kg poly Oxyethylene polyoxypropanol amine ether, 24Kg tetramethylurea, 37Kg polyethylene glycol, and 80Kg water we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com