Method for preparing biphenyl triarylated amine compound by taking carboxyl as guide group, intermediate and preparation method thereof

A triarylamine and biphenyl-type technology, which is applied in the synthesis field of biphenyl-type triarylamine compounds, can solve the problems of high industrial production costs, and achieve the effects of reducing industrial production costs, production costs, and reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

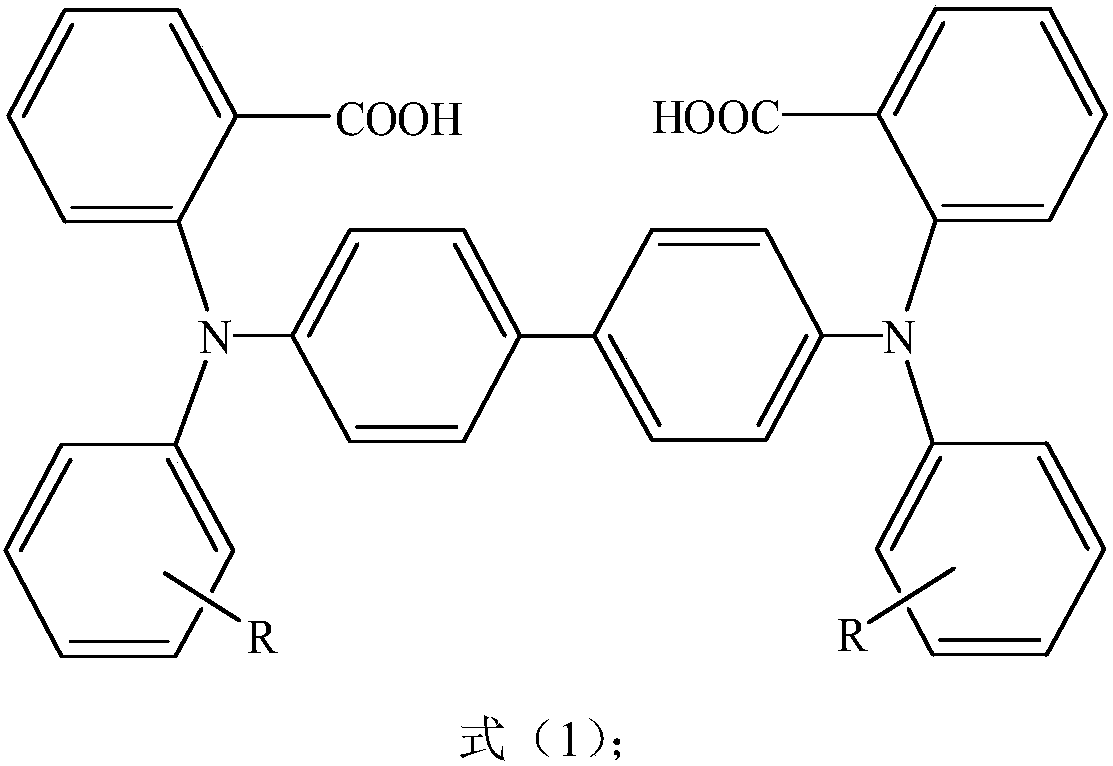

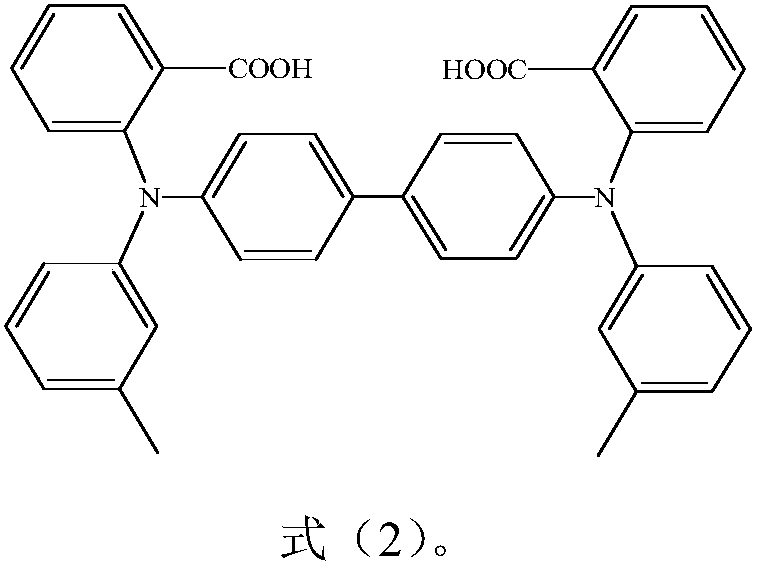

[0035] The intermediate used to prepare the biphenyl type triarylamine compound in this embodiment has a structural formula as shown in formula (2):

[0036]

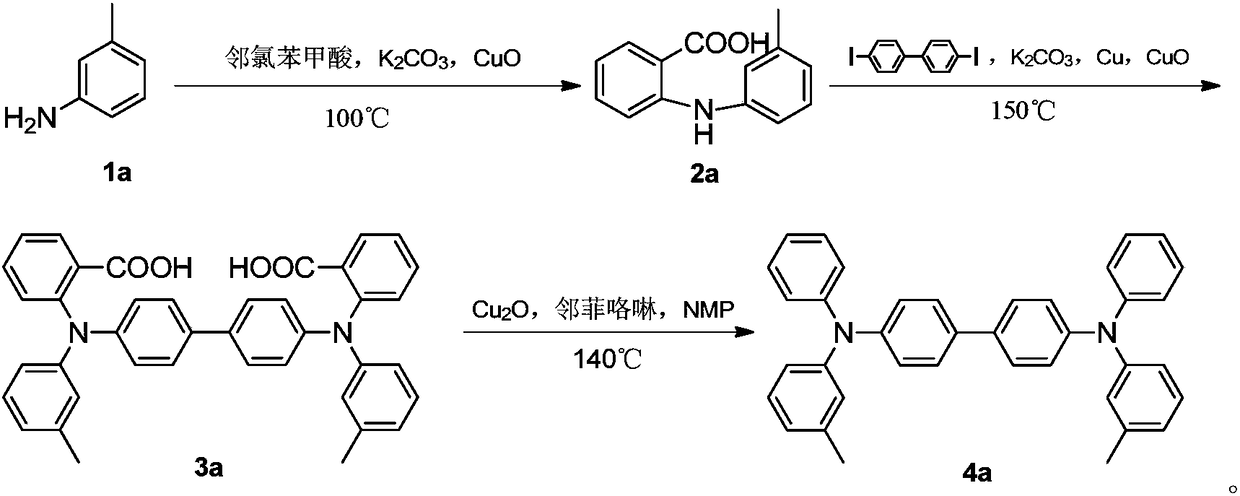

[0037] The method for preparing biphenyl type triarylamine compounds with carboxyl group as the guiding group in this embodiment, the process route is as follows:

[0038]

[0039] Specific steps are as follows:

[0040] 1) Synthesis of intermediates

[0041] 1. add 4.00kg water in the reactor with thermometer and reflux device, add o-chlorobenzoic acid 2.00kg, potassium carbonate 2.00kg, copper oxide 0.02kg and 3-methylaniline (1a) 1.00kg successively while stirring, Raise the temperature of the system to 100°C to react, monitor the reaction to the end by TLC, stop heating; cool the system to 60°C, add 0.16 kg of activated carbon for decolorization, continue to stir until the system is uniform, then filter, and then add concentrated 30-36% Adjust the pH of the filtrate to 1 with hydrochloric acid. At this time,...

Embodiment 2

[0046] The intermediate used to prepare the biphenyl triarylamine compound in this example has the same structural formula as in Example 1.

[0047] The method for preparing biphenyl triarylamine compounds with carboxyl as the guiding group in this embodiment, the process route is as follows:

[0048]

[0049] Specific steps are as follows:

[0050] 1) Synthesis of intermediates

[0051] 1. add 10.05kg water in the reactor with thermometer and reflux device, add o-chlorobenzoic acid 2.00kg, sodium carbonate 4.50kg, copper oxide 0.11kg and 3-methylaniline (1a) 1.30kg successively while stirring, Raise the temperature of the system to 103°C to react, monitor the reaction to the end by TLC, stop heating; cool the system to 70°C, add 0.20 kg of activated carbon, continue to stir until the system is uniform, then filter, then add concentrated hydrochloric acid with a concentration of 35% to adjust the pH value of the filtrate =1, at this time, a product is precipitated, and th...

Embodiment 3

[0056] The intermediate used to prepare the biphenyl triarylamine compound in this example has the same structural formula as in Example 1.

[0057] The method for preparing biphenyl triarylamine compounds with carboxyl as the guiding group in this embodiment, the process route is as follows:

[0058]

[0059] Specific steps are as follows:

[0060] 1) Synthesis of intermediates

[0061] 1. add 20.00kg water in the reactor with thermometer and reflux device, add 2.00kg o-chlorobenzoic acid, cesium carbonate 7.00kg, copper powder 0.10kg, copper oxide 0.10kg and 3-methylaniline ( 1a) 1.60kg, raise the temperature of the system to 105°C to react, monitor the reaction to the end point by TLC, stop heating; cool the system to 80°C, add 0.24kg of activated carbon, continue to stir until the system is uniform and then filter, then add concentrated hydrochloric acid with a concentration of 36% Adjust the pH value of the filtrate to 1. At this time, a product is precipitated. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com