Ultraviolet (UV) viscosity-reducing composition as well as UV viscosity-reducing film and preparation method thereof

A composition and film technology, applied in the direction of film/sheet adhesives, non-polymer adhesive additives, adhesives, etc., can solve the problems of residue, contamination by the attached object, etc., to achieve high production efficiency, easy The effect of peeling and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

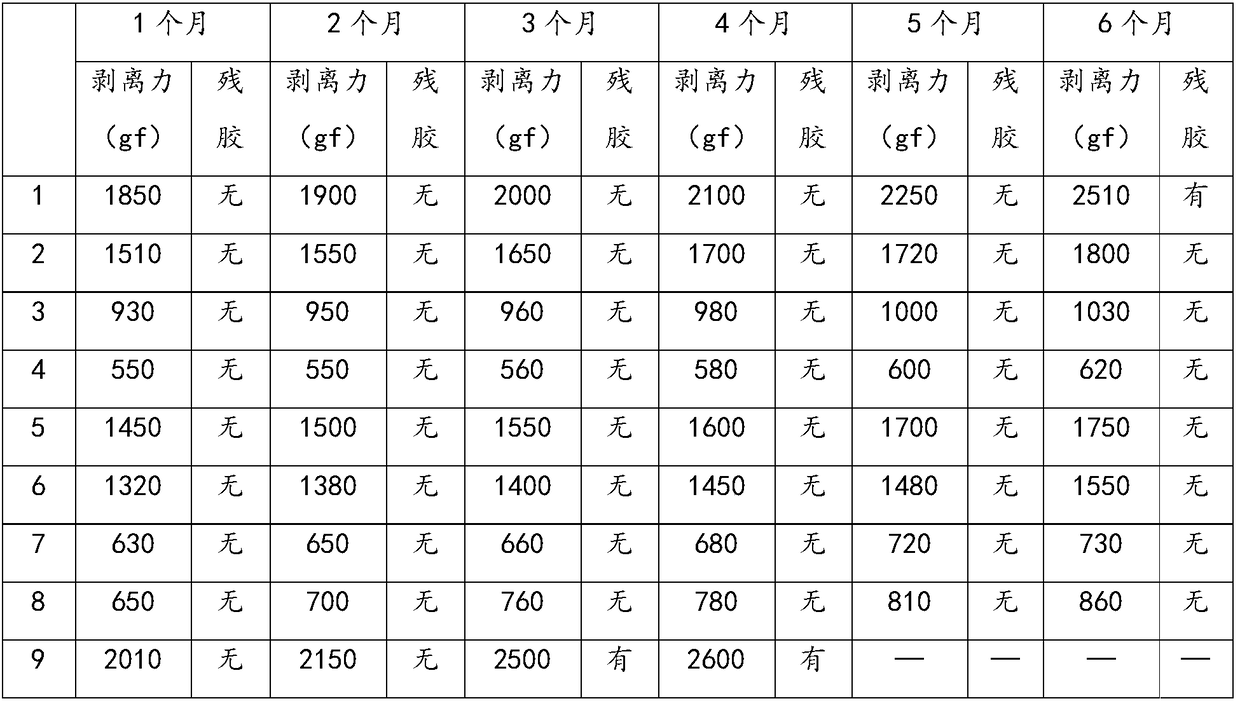

Examples

Embodiment 1

[0061] The UV viscosity-reducing composition described in the present embodiment, the raw material composition is as follows:

[0062] 40g acrylic pressure-sensitive adhesive resin (manufacturer: Shanghai Toyo Ink Manufacturing Co., Ltd., model: STS0119OP), 20g multifunctional oligomer (manufacturer: Huayao Chemical (Wuxi) Co., Ltd., model: UX-8620W), 1g Crosslinking agent (manufacturer: Bayer, Germany, model: N3390), 1g of azobisisoheptanonitrile, 5g of 2,4,6-(trimethylbenzoyl)-diphenylphosphine oxide (TPO), 33 g of butanone.

[0063] Wherein, the average molecular weight of the STS0119OP is 600,000, the solid content is 25%, and the viscosity is 10,000 cps. The UX-8620W is an aliphatic urethane acrylate oligomer.

Embodiment 2

[0065] The UV viscosity-reducing composition described in the present embodiment, the raw material composition is as follows:

[0066] 40g acrylic pressure-sensitive adhesive resin (manufacturer: Shanghai Toyo Ink Manufacturing Co., Ltd., model: STS0119OP), 20g multifunctional oligomer (manufacturer: Huayao Chemical (Wuxi) Co., Ltd., model: UX-8620W), 1g Crosslinking agent (manufacturer: Bayer, Germany, model: N3390), 1.5g of azobisisoheptanonitrile, 5g of 2,4,6-(trimethylbenzoyl)-diphenylphosphine oxide (TPO) , 32.5 g of butanone.

Embodiment 3

[0068] The UV viscosity-reducing composition described in the present embodiment, the raw material composition is as follows:

[0069] 40g acrylic pressure-sensitive adhesive resin (manufacturer: Shanghai Toyo Ink Manufacturing Co., Ltd., model: STS0119OP), 20g multifunctional oligomer (manufacturer: Huayao Chemical (Wuxi) Co., Ltd., model: UX-8620W), 1g Crosslinking agent (manufacturer: Bayer, Germany, model: N3390), 2g of azobisisoheptanonitrile, 5g of 2,4,6-(trimethylbenzoyl)-diphenylphosphine oxide (TPO), 32 g of butanone.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com