Remediation agent for tobacco soil

A soil remediation agent and tobacco technology, applied in the restoration of polluted soil, soil conditioning materials, organic fertilizers, etc., can solve the problems of soil remediation that have not been mentioned, achieve high-efficiency heavy metal complexation, simple preparation method, and easy operation safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

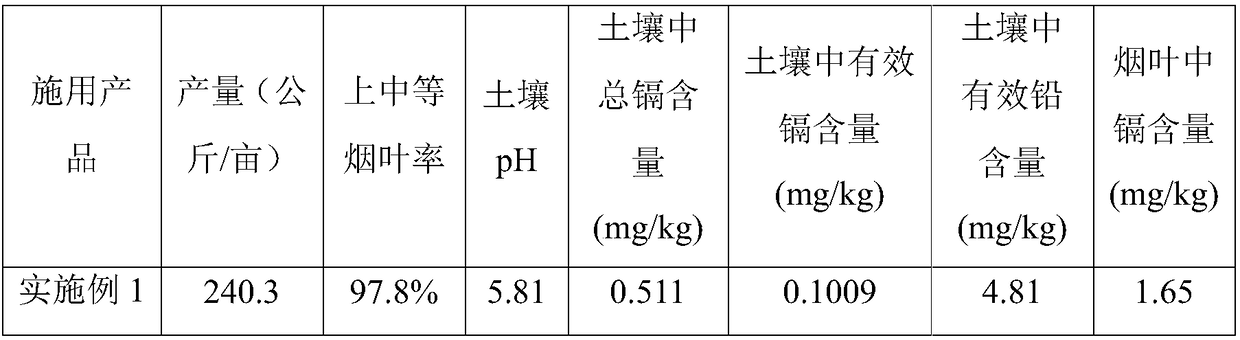

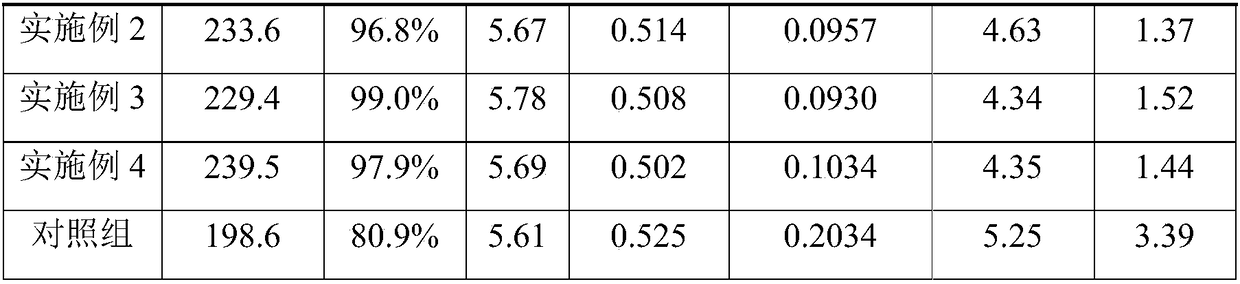

Examples

Embodiment 1

[0037] A tobacco soil remediation agent, comprising 15 parts of biomass charcoal, 25 parts of sodium humate, 15 parts of trimercaptotriazine trisodium salt, 20 parts of general calcium, 15 parts of zinc sulfate, 20 parts of urea, and 15 parts of potassium dihydrogen phosphate , 5 parts of sodium silicate, 15 parts of proline.

[0038] Preparation method, concrete steps are as follows:

[0039] 1) Grind tobacco waste (such as tobacco stems, tobacco waste, unsuitable tobacco leaves, etc.) The final material is added to the pyrolysis reactor, and the carbonization reaction is carried out at 550°C for 10 minutes under anaerobic conditions to obtain biochar with a loose structure;

[0040] 2) Sodium humate, urea, and trimercaptotriazine trisodium salt are dissolved in water at room temperature and mixed evenly. The total amount of sodium humate, urea, and trimercaptotriazine trisodium salt to water is 1:4, to obtain a mixed solution;

Embodiment 2

[0044] A tobacco soil remediation agent, comprising 10 parts of biomass charcoal, 35 parts of sodium humate, 15 parts of trimercaptotriazine trisodium salt, 10 parts of general calcium, 25 parts of zinc sulfate, 10 parts of urea, and 25 parts of potassium dihydrogen phosphate , 5 parts of sodium silicate and 16 parts of proline.

[0045] Preparation method, concrete steps are as follows:

[0046] 1) Grind tobacco waste (such as tobacco stems, tobacco waste, unsuitable tobacco leaves, etc.) The final material is added to the pyrolysis reactor, and the carbonization reaction is carried out under anaerobic conditions at 350°C for 30 minutes to obtain biochar with a loose structure;

[0047] 2) Sodium humate, urea, and trimercaptotriazine trisodium salt are dissolved in water at room temperature and mixed evenly. The total amount of sodium humate, urea, and trimercaptotriazine trisodium salt to water is 1:5, to obtain a mixed solution;

[0048] 3) Pulverize common calcium, zinc...

Embodiment 3

[0051] A tobacco soil remediation agent, comprising 20 parts of biomass charcoal, 20 parts of sodium humate, 25 parts of trimercaptotriazine trisodium salt, 25 parts of general calcium, 10 parts of zinc sulfate, 25 parts of urea, and 10 parts of potassium dihydrogen phosphate , 10 parts of sodium silicate and 7 parts of proline.

[0052] Preparation method, concrete steps are as follows:

[0053] 1) Grind tobacco waste (such as tobacco stems, tobacco waste, unsuitable tobacco leaves, etc.) The final material is added to the pyrolysis reactor, and the carbonization reaction is carried out at 450°C for 20 minutes under anaerobic conditions to obtain biochar with a loose structure;

[0054] 2) Sodium humate, urea, and trimercaptotriazine trisodium salt are dissolved in water at room temperature and mixed evenly. The total amount of sodium humate, urea, and trimercaptotriazine trisodium salt to water is 1:4, to obtain a mixed solution;

[0055] 3) Pulverize common calcium, zinc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com