A kind of bipolar bistable memristor and preparation method thereof

A memristor and bistable technology, which is applied in the field of micro-nano electronic devices, can solve the problems of slow response speed, poor stability, and low memory cell density of memristors, so as to reduce power consumption, improve stability, and avoid unevenness. uneven effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

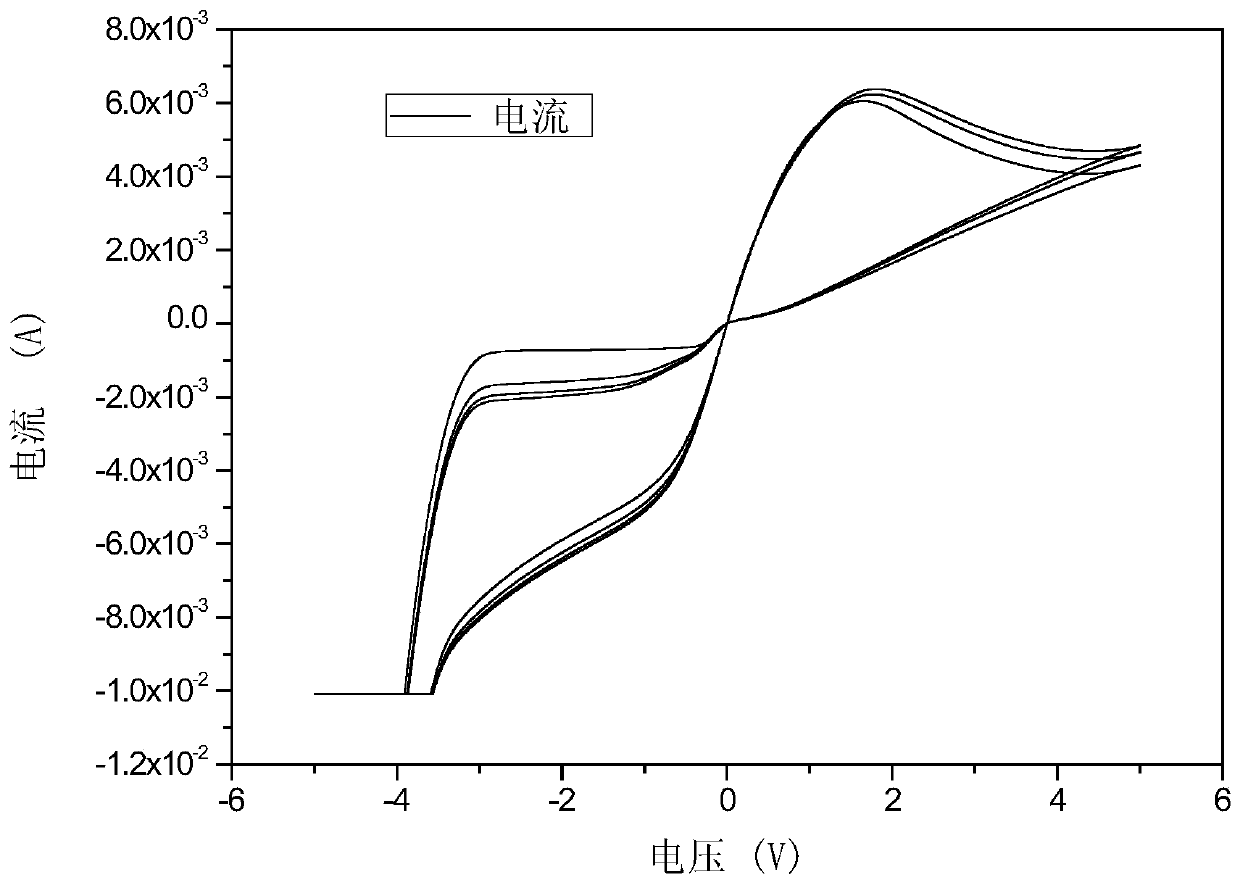

[0021] The surface of the FTO conductive glass is ultrasonically cleaned with acetone and alcohol successively to obtain the FTO conductive glass bottom electrode. The acid solution of tetrabutyl titanate (the acid solution is a hydrochloric acid aqueous solution with a mass fraction of 50%) is prepared according to the titanium element concentration of 0.07 mol / L. Will be 4cm 2 FTO conductive glass is placed in an autoclave, and then 0.238ml of acid solution of tetrabutyl titanate is added. After the device is compressed, it is placed in a blast drying oven and heated at 130°C for 4 hours. After the reaction is completed, take out the sample The parts are cleaned with pure water to neutrality to obtain FTO conductive glass on which titanium dioxide nanowire arrays are grown on the surface. Its microscopic appearance is like figure 1 As shown, it can be seen from the figure that a layer of titanium dioxide nanowire arrays are grown on FTO conductive glass. The nanowire arrays a...

Embodiment 2

[0027] The surface of the FTO conductive glass is ultrasonically cleaned with acetone and alcohol successively to obtain the FTO conductive glass bottom electrode. An acid solution of tetrabutyl titanate (the acid solution is a hydrochloric acid aqueous solution with a mass fraction of 50%) is prepared according to the titanium element concentration of 0.03 mol / L. Will be 4cm 2 FTO conductive glass is placed in an autoclave, and then 0.1ml of acid solution of tetrabutyl titanate is added. After pressing the device, it is placed in a blast drying oven and heated at 200°C for 1 hour. After the reaction is completed, take out the sample The parts are cleaned with pure water to neutrality to obtain FTO conductive glass on which titanium dioxide nanowire arrays are grown on the surface. The average length of the obtained titanium dioxide nanowires was 1 um, and the average diameter of the nanowires was 100 nm.

[0028] Then a layer of titanium dioxide film is suspended on the titaniu...

Embodiment 3

[0032] The surface of the FTO conductive glass is ultrasonically cleaned with acetone and alcohol successively to obtain the FTO conductive glass bottom electrode. An acid solution of tetrabutyl titanate (the acid solution is an aqueous hydrochloric acid solution with a mass fraction of 50%) is prepared according to the titanium element concentration of 0.1 mol / L. Will be 4cm 2 FTO conductive glass is placed in the autoclave, and then 0.340ml of acid solution of tetrabutyl titanate is added. After the device is compressed, it is placed in a blast drying box and heated at 80°C for 48 hours. After the reaction is completed, take out the sample The parts are cleaned with pure water to neutrality to obtain FTO conductive glass on which titanium dioxide nanowire arrays are grown on the surface. The average length of the obtained titanium dioxide nanowires is 6um, and the average diameter of the nanowires is 200nm.

[0033] Then, a layer of titanium dioxide film was suspended on the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com