Preparation method for food-grade calcium hydroxide

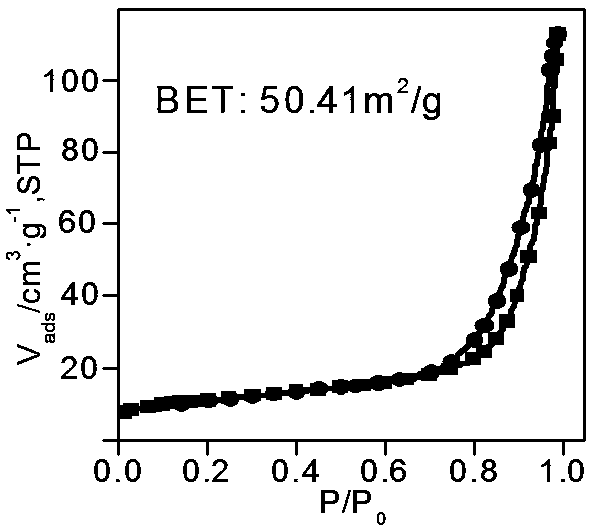

A calcium hydroxide, food-grade technology, applied in the field of preparation of food-grade calcium hydroxide, can solve the problems of low product quality, agglomeration, low specific surface area, etc., to prolong residence time, improve conversion rate and specific surface area, The effect of high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The present embodiment provides a kind of preparation method of food grade calcium hydroxide, comprises the following steps:

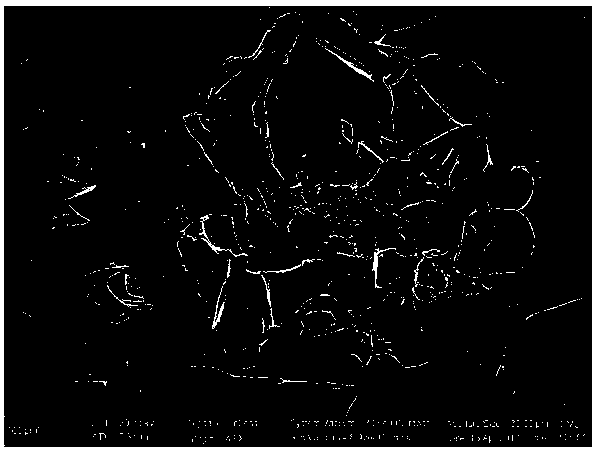

[0032] Step 1: Pour quicklime particles into a drum-type ball mill to obtain powdery particles with a particle size of 200-500 μm after ball milling. The outlet of the ball mill is connected to a bucket elevator, and after ball milling, the powdery particles are transported to the quicklime silo; like figure 1 Shown is a scanning electron microscope image of calcium oxide after ball milling, and it can be seen from the figure that the particle size of calcium oxide powder particles is in the range of 200-500 μm.

[0033] Step 2: The powdery particles in the quicklime silo are transported to the primary digester through spiral electronic metering. In order to prevent dust pollution on site, all material reactions are carried out in the pipeline, and the primary digester is equipped with a spraying device. The exterior is equipped with a cold wat...

Embodiment 1

[0050] The preparation method of the food-grade calcium hydroxide provided by the present embodiment comprises the following steps:

[0051] Step 1: Pour the quicklime particles into a drum-type ball mill, where the ball-to-material ratio is 40:1, and mill for 10 hours; after ball milling, powdery particles with a particle size of 200-500 μm are obtained, and the outlet of the ball mill is connected to a bucket elevator, and the ball mill Finally, the powdery particles are transported to the quicklime silo;

[0052] Step 2: The powdery particles in the quicklime silo are transported to the three-axis rotary quicklime digester through spiral electronic metering. In order to prevent dust pollution on site, all material reactions are carried out in the pipeline, and the three-axis rotary quicklime digester The interior is equipped with a spraying device, and the exterior is equipped with a cold water jacket; the spraying device sprays a mixed solvent of water and alcohol solvent,...

Embodiment 2

[0056] The preparation method of the food-grade calcium hydroxide provided by the present embodiment comprises the following steps:

[0057] Step 1: Pour quicklime particles into a drum-type ball mill, where the ball-to-material ratio is 20:1, and mill for 4 hours; after ball milling, powdery particles with a particle size of 200-500 μm are obtained. The outlet of the ball mill is connected to a bucket elevator, and the ball mill is Finally, the powdery particles are transported to the quicklime silo;

[0058] Step 2: The powdery particles in the quicklime silo are transported to the three-axis rotary quicklime digester through spiral electronic metering. In order to prevent dust pollution on site, all material reactions are carried out in the pipeline, and the three-axis rotary quicklime digester The interior is equipped with a spraying device and the exterior is equipped with a cold water jacket; the spraying device sprays a mixed solvent of water and alcohol solvent, the ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com