Preparation method of polycarboxylic acid water reducing agent suitable for mortar

A technology of polycarboxylic acid and water reducing agent, which is applied in the field of concrete admixture and building materials, can solve the problem of incapability of transplanting concrete water reducing agent, and achieve the effect of increasing workability, strong water retention capacity and good fluidity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

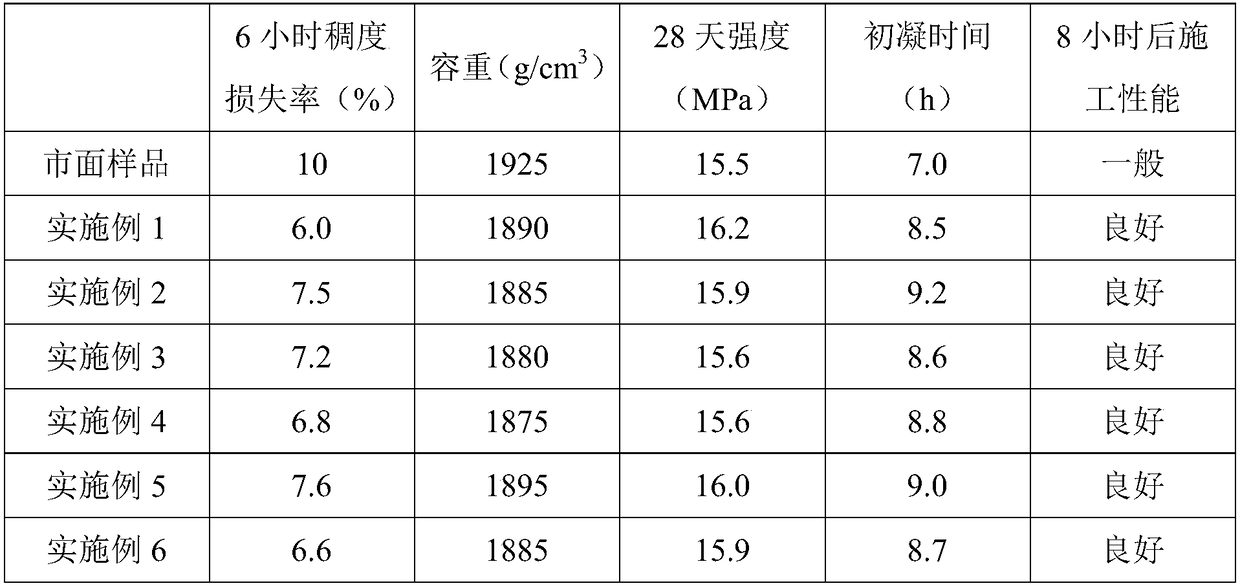

Examples

Embodiment 1

[0028] A preparation method suitable for a polycarboxylate water reducer for mortar, characterized in that it comprises the following steps:

[0029] 1) 110 parts of allyl polyoxyethylene ether with a molecular weight of 3000, 20 parts with a molecular weight of 5×10 5 , quaternary ammonium alkyl starch with a degree of substitution of 0.1, 200 parts with a molecular weight of 5×10 5 1. Add carboxymethyl starch with a degree of substitution of 0.6, 15 parts of acrylic acid and 250 parts of water into the reactor, and stir to dissolve it;

[0030] 2) Measure the temperature in the kettle, control the temperature in the kettle at 55°C, after the temperature is stable, add 1.8 parts of hydrogen peroxide at one time;

[0031] 3) After adding hydrogen peroxide for 5 minutes, start to drop the initiator and the small monomer solution in sequence. After the initiator is added, start to add the small monomer solution dropwise within 10 minutes. The small monomer solution is added for...

Embodiment 2

[0034] A preparation method suitable for a polycarboxylate water reducer for mortar, characterized in that it comprises the following steps:

[0035] 1) 120 parts of methallyl polyoxyethylene ether with a molecular weight of 3200, 24 parts with a molecular weight of 6×10 5 , tertiary amine alkyl starch with a degree of substitution of 0.15, 190 parts with a molecular weight of 6×10 5 1. Add carboxymethyl starch with a substitution degree of 0.7, 14 parts of acrylic acid and 230 parts of water into the reaction kettle, and stir to dissolve it;

[0036] 2) Measure the temperature in the kettle, control the temperature in the kettle at 49°C, after the temperature is stable, add 2 parts of hydrogen peroxide at one time;

[0037] 3) After adding hydrogen peroxide for 5 minutes, start to drop the initiator and the small monomer solution in sequence. After the initiator is added, start to add the small monomer solution dropwise within 10 minutes. The small monomer solution dripping ...

Embodiment 3

[0040] A preparation method suitable for a polycarboxylate water reducer for mortar, characterized in that it comprises the following steps:

[0041] 1) 137 parts of vinyl butyl ether polyoxyethylene ether with a molecular weight of 3500, 33 parts with a mass ratio of 1:1 and a molecular weight of 7×10 5 , a tertiary amine alkyl starch with a degree of substitution of 0.6 and a molecular weight of 7×10 5 1. A composition of quaternary ammonium alkyl starch with a degree of substitution of 0.3, 170 parts of carboxymethyl starch, 11 parts of acrylic acid and 210 parts of water are added to the reaction kettle, stirred to dissolve;

[0042] 2) Measure the temperature in the kettle, control the temperature in the kettle at 44°C, after the temperature stabilizes, add 2.3 parts of hydrogen peroxide at one time;

[0043] 3) After adding hydrogen peroxide for 5 minutes, start to drop the initiator and the small monomer solution in sequence. After the initiator is added, start to add ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com