A method for preparing building materials using microbial activated sludge

A technology of microbial activity and building materials, which is applied in the field of preparing building materials from microbial activated sludge, can solve problems such as low compressive strength, high microbial content in sludge, and potential safety hazards, and achieve low cost, high combustion efficiency, and heat reduction wasteful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

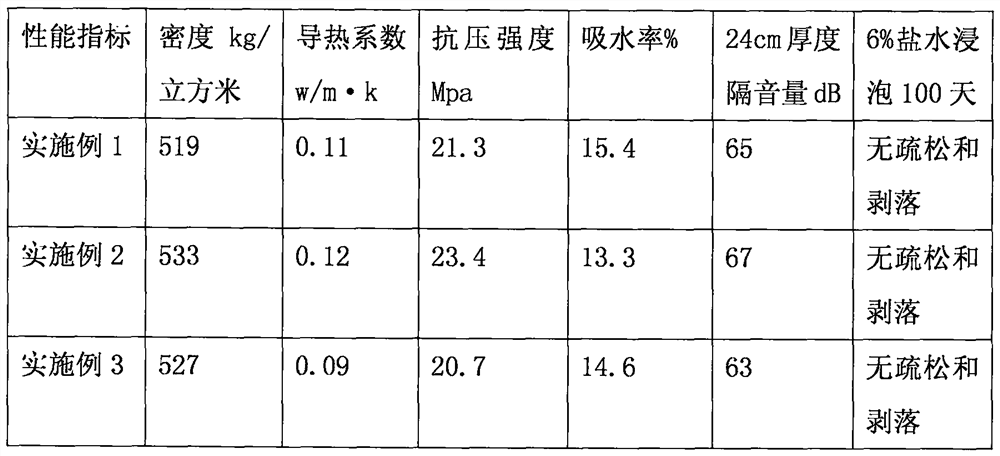

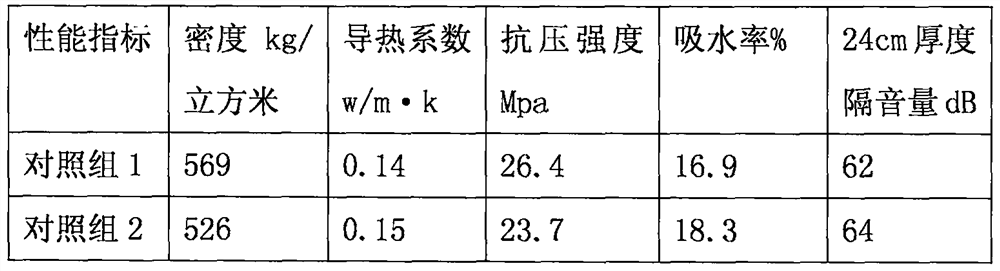

Examples

Embodiment 1

[0032] A kind of method utilizing microbial activated sludge to prepare building material, it specifically comprises the steps:

[0033] Dividing the dewatered microbial activated sludge into a large portion of microbial activated sludge and a small portion of microbial activated sludge, wherein the large portion of microbial activated sludge is used for combustion, and the small portion of microbial activated sludge is used to prepare foaming agents;

[0034] Adding fine coal to a large amount of microbial activated sludge to obtain fuel sludge, the amount of fine coal added accounts for 10% of the sludge mass; sending the fuel sludge into the incinerator for combustion, collecting combustion waste residue, and obtaining heat, The heat is collected by the heat collection and conversion device and supplied to the dehydrator;

[0035] Dry a small portion of microbial activated sludge until the moisture content is lower than 20wt%, then add the same mass of 3M hydrochloric acid ...

Embodiment 2

[0041] A kind of method utilizing microbial activated sludge to prepare building material, it specifically comprises the steps:

[0042] Dividing the dewatered microbial activated sludge into a large portion of microbial activated sludge and a small portion of microbial activated sludge, wherein the large portion of microbial activated sludge is used for combustion, and the small portion of microbial activated sludge is used to prepare foaming agents;

[0043] Adding fine coal to a large amount of microbial activated sludge to obtain fuel sludge, the amount of fine coal added accounts for 10% of the sludge mass; sending the fuel sludge into the incinerator for combustion, collecting combustion waste residue, and obtaining heat, The heat is collected by the heat collection and conversion device and supplied to the dehydrator;

[0044] Dry a small portion of microbial activated sludge until the water content is lower than 20wt%, then add the same mass of 3M hydrochloric acid sol...

Embodiment 3

[0050] A kind of method utilizing microbial activated sludge to prepare building material, it specifically comprises the steps:

[0051] Dividing the dewatered microbial activated sludge into a large portion of microbial activated sludge and a small portion of microbial activated sludge, wherein the large portion of microbial activated sludge is used for combustion, and the small portion of microbial activated sludge is used to prepare foaming agents;

[0052] Adding fine coal to a large amount of microbial activated sludge to obtain fuel sludge, the amount of fine coal added accounts for 8% of the sludge mass; the fuel sludge is sent to the incinerator for combustion, the combustion waste residue is collected, and heat is obtained. The heat is collected by the heat collection and conversion device and supplied to the dehydrator;

[0053] Dry a small portion of microbial activated sludge until the moisture content is lower than 20wt%, then add the same mass of 3.5M hydrochlori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com