A complete set of equipment and method for preparing open-cell foam metal

A technology for open-cell foam and complete sets of equipment is applied in the field of complete sets of equipment for preparing open-cell metal foams, which can solve the problems of inapplicability, lack of continuity, low production efficiency, etc., to ensure the consistency of performance, improve efficiency and safety. , the effect of saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

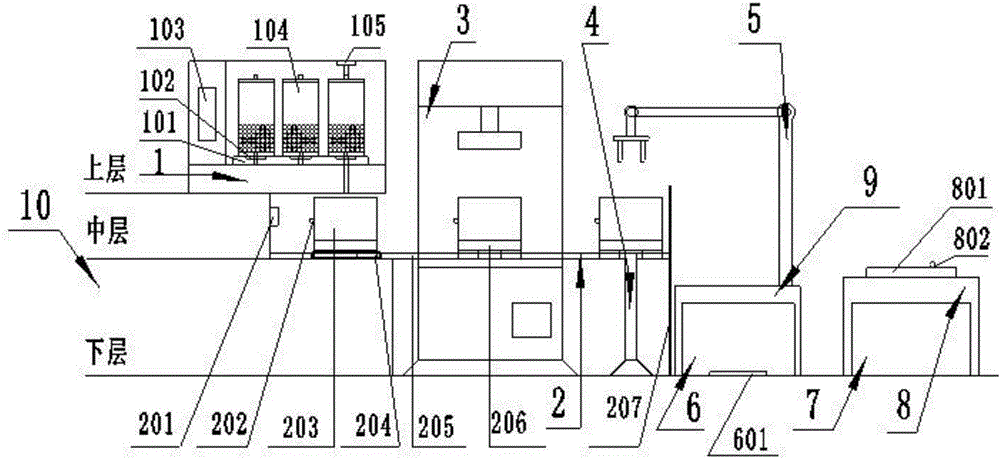

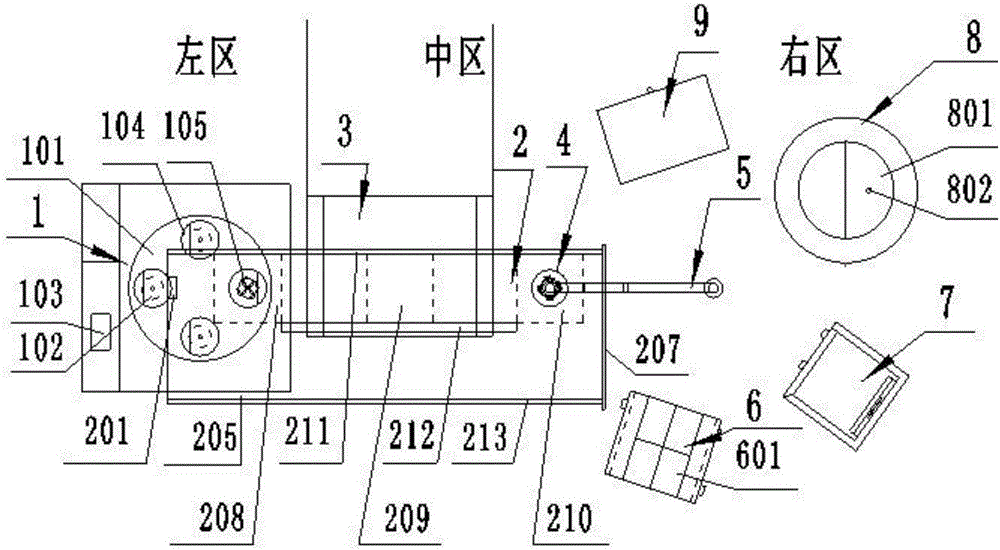

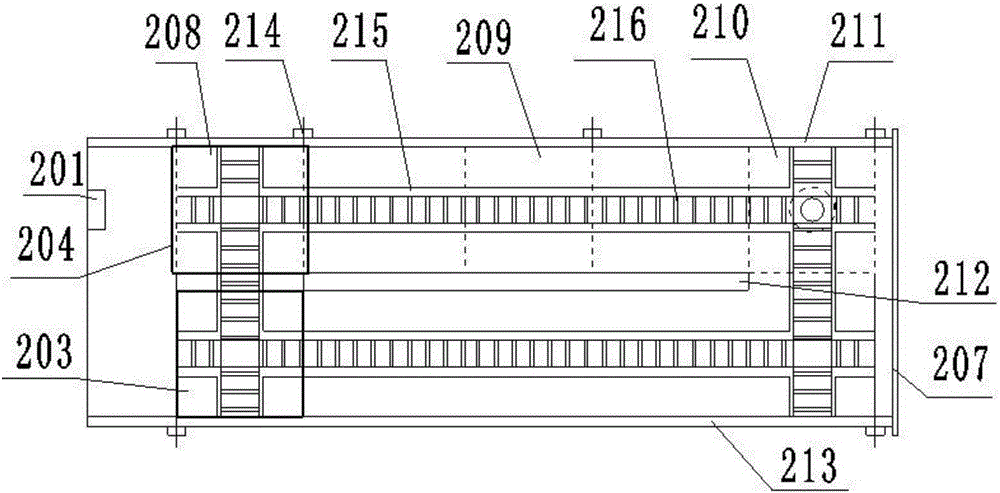

[0063] The complete set of equipment for preparing open-cell metal foam in this embodiment includes a powder mixer 1, a mold return transfer device 2, a pressure device 3, an ejector device 4, a manipulator device 5, a pore-forming agent dissolution pool 6, a blast drying oven 7, Holding furnace 8, cooling water pool 9 and operating platform 10; described operating platform 10 comprises upper, middle and lower three-layer table tops, and the three-layer table tops are distributed sequentially in a ladder shape, and the left and right boundaries of the pressure device 3 are bounded by the operation platform from left to right. To the right, it is divided into left area, middle area and right area in turn. The upper table is equipped with a powder mixer 1 and is located in the left area; the pressure device 3 is located in the middle area of the lower table, and the ejector device 4 is located on the right side of the lower table. In the area; the mold back-shaped conveying dev...

Embodiment 2

[0077]Present embodiment adopts the complete set of equipment of embodiment 1, present embodiment prepares open-cell magnesium foam, and concrete method is:

[0078] 1) Select cubic salt particles with a diameter of 4 mm as the pore-forming agent, and select magnesium alloy powder with a diameter of 300 μm as the raw material.

[0079] 2) Mix the powder evenly, grind the raw materials for 30 minutes at a speed of 150r / min in the powder mixer 1 (select 4 powder mixing tanks of the same model); weigh the salt granules according to the mass ratio of the salt granules to the magnesium powder being 0.10, After mixing at a speed of 300r / min for 40 minutes, increase the speed to 450r / min, and mix for 30 minutes to obtain a uniformly mixed powder;

[0080] 3) charging, blowing the homogeneously mixed powder in step 2) into the mold 203 through a blower, and vibrating for 20 minutes to make the powder evenly distributed in the mold 203;

[0081] 4) Pressing, the mold 203 filled with p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com