PVDF film containing metal nano titanium powder and preparation method and application thereof

A metal nano, nano titanium technology, applied in chemical instruments and methods, general water supply conservation, water/sludge/sewage treatment, etc., can solve the problems of insufficient solar energy utilization, limited application, high price, etc., and achieve cost and energy savings. consumption, improved protection, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The invention provides a kind of preparation method of the PVDF film containing metal nano-titanium powder, it comprises the following steps:

[0038] Step 1: Use PVDF powder to prepare PVDF organic solution. The specific method is: dissolve PVDF powder in an organic solvent and stir and mix evenly; preferably, the organic solvent is N, N-dimethylformamide (DMF) or N - methylpyrrolidone (NMP);

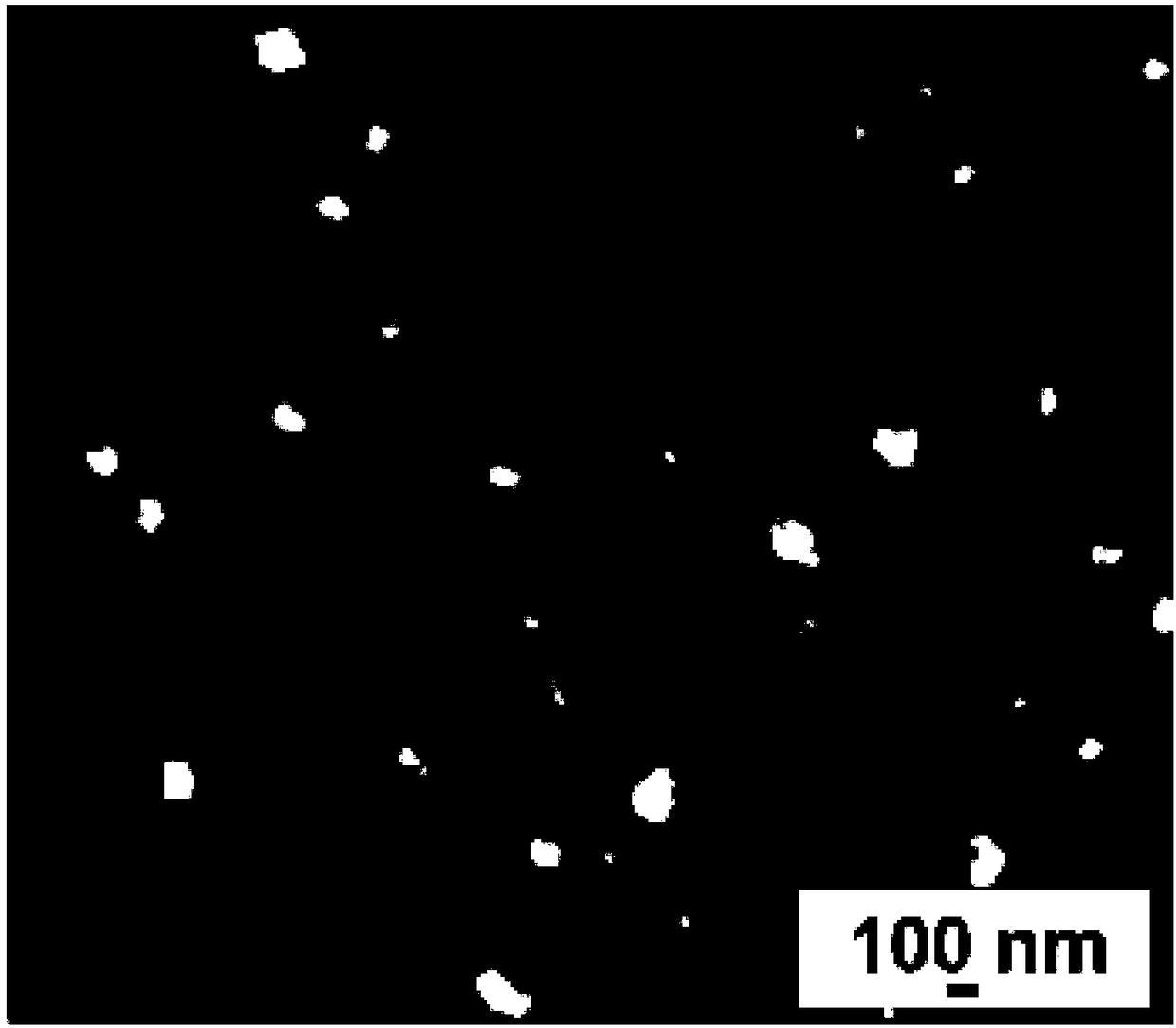

[0039] Step 2: Add metallic nano-titanium powder to the PVDF organic solution and mix evenly;

[0040] Step 3: Spread the above solution evenly on the surface of the flat glass to form a thin film;

[0041] Step 4: Place the flat glass coated with the film in step 3 in water and soak it for a period of time, then take out the film and dry it, so as to prepare a PVDF film containing metal nano-titanium powder.

[0042] The present invention also provides a PVDF film containing metal nano-titanium powder, wherein the PVDF film containing metal nano-titanium powder is made by the a...

Embodiment 1

[0046] Add 14.5 mg of metallic nano-titanium powder into a beaker containing 1 mL of polyvinylidene fluoride organic solution, and sonicate for 15 min to obtain a uniform mixed solution. Take out 0.5mL of the above mixed solution with a dropper, and apply it on a dry and clean flat glass surface with an applicator to form a PVDF film with a size of 8cm×8cm and a thickness of about 150μm. Then the flat glass coated with Ti / PVDF film was quickly immersed in deionized water, and then the Ti / PVDF film was taken out, rinsed with water and ethanol several times, and finally placed in an oven at 50°C for 2 hours. The dried Ti / PVDF film was cut into a circular film with a diameter of 33.5 mm, and a PVDF film with a thickness of about 150 μm and a titanium powder content of about 1 mg was successfully prepared.

Embodiment 2

[0048] Add 29 mg of metal nano-titanium powder into a beaker containing 1 mL of polyvinylidene fluoride organic solution, and sonicate for 15 min to obtain a uniform mixed solution. Take out 0.5mL of the above mixed solution with a dropper, and apply it on a dry and clean flat glass surface with an applicator to form a PVDF film with a size of 8cm×8cm and a thickness of about 150μm. Then the flat glass coated with Ti / PVDF film was quickly immersed in deionized water, and then the Ti / PVDF film was taken out, rinsed with water and ethanol several times, and finally placed in an oven at 50°C for 2 hours. The dried Ti / PVDF film was cut into a circular film with a diameter of 33.5 mm, and a PVDF film with a thickness of about 150 μm and a titanium powder content of about 2 mg was successfully prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com