Expose the tio of the 001 and 101 crystal planes 2 / sepiolite composite gel and preparation method thereof

A composite gel, sepiolite technology, applied in chemical instruments and methods, water/sludge/sewage treatment, other chemical processes, etc., can solve problems such as the inability to solve the problem of TiO2 aggregation, and achieve solid-liquid separation difficulties, The effect of novel structure and strong photocatalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] (1) Add a certain amount of titanium source into the acetic acid solution, stir and dissolve at 40°C for 24 hours, wherein the mass ratio of titanium to acetic acid (analytical pure) is 0.28:40, and the titanium source in this example is tetrabutyl titanate ester;

[0053] (2) A certain amount of sepiolite is ultrasonically dispersed in acetic acid solution at 100W for 1h, and then stirred at a stirring speed of 200r / min for 0.5h, wherein the mass ratio of sepiolite to acetic acid is 1:300;

[0054] (3) dissolving CTAB in water at 30°C, wherein the mass ratio of CTAB to water is 9:1000;

[0055] (4) Mix the solutions prepared in steps (1), (2) and (3), and stir at 40°C for 40min;

[0056] (5) Put the solution prepared in step (4) into a polytetrafluoroethylene reactor for solvothermal reaction, the solvothermal temperature is 140° C., and the solvothermal time is 24 hours. Obtain TiO with exposed 001 and 101 crystal planes 2 / Sepiolite Composite Gel.

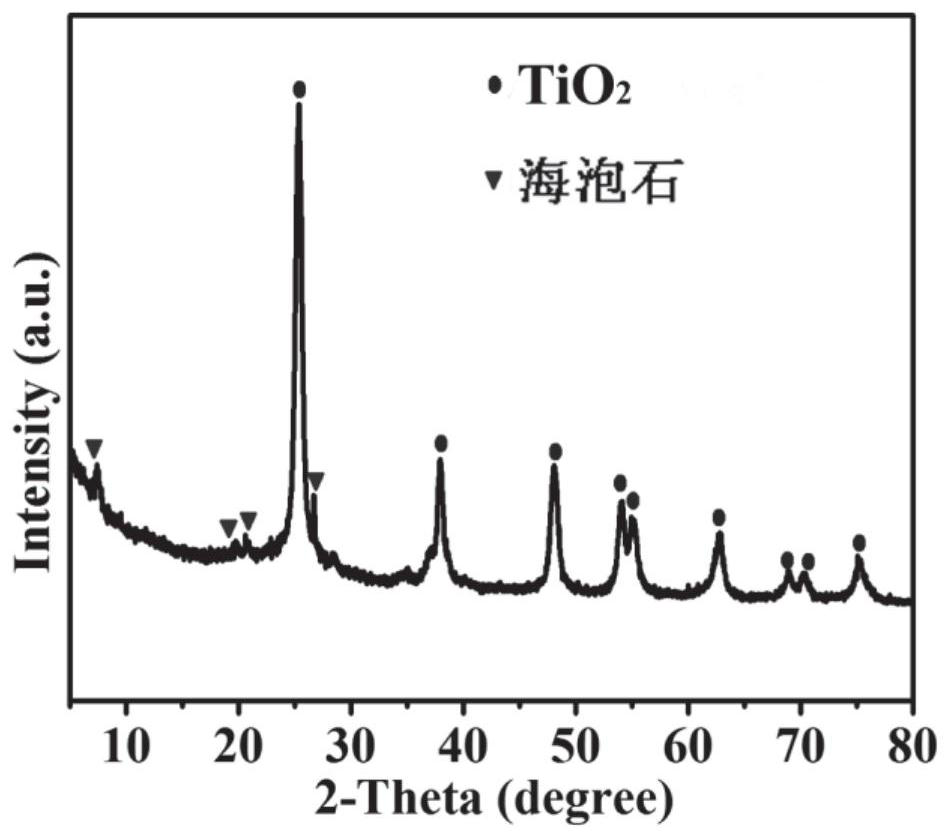

[0057] The T...

Embodiment 2

[0063] (1) Add a certain amount of titanium source into the acetic acid solution, stir and dissolve at 40°C for 24 hours, wherein the mass ratio of titanium to acetic acid is 0.28:40, and the titanium source in this embodiment is tetrabutyl titanate;

[0064] (2) A certain amount of sepiolite is ultrasonically dispersed in acetic acid solution at 100W for 1h, and then stirred at a stirring speed of 200r / min for 0.5h, wherein the mass ratio of sepiolite to acetic acid is 1:300;

[0065] (3) dissolving CTAB in water at 30°C, wherein the mass ratio of CTAB to water is 9:1000;

[0066] (4) Mix the solutions prepared in steps (1), (2) and (3), and stir at 40°C for 40min;

[0067] (5) Put the solution prepared in step (4) into a polytetrafluoroethylene reactor for solvothermal reaction, the solvothermal temperature is 100° C., and the solvothermal time is 24 hours. Obtain TiO with exposed 001 and 101 crystal planes 2 / Sepiolite Composite Gel.

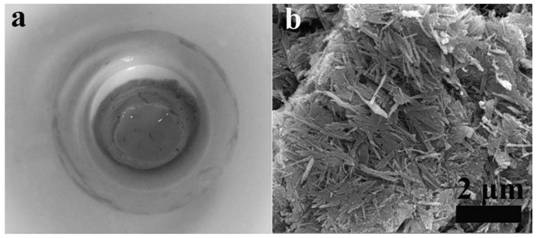

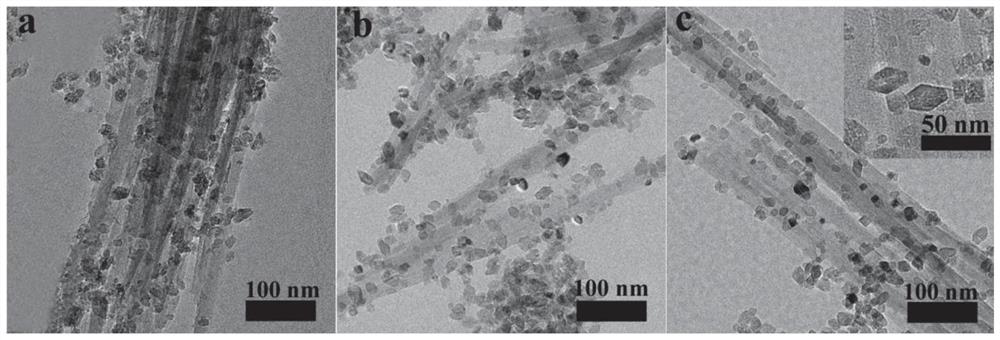

[0068] figure 2 a is the TiO pre...

Embodiment 3

[0070] (1) Add a certain amount of titanium source into the acetic acid solution, stir and dissolve at 40°C for 24 hours, wherein the mass ratio of titanium to acetic acid is 0.28:40, and the titanium source in this embodiment is tetrabutyl titanate;

[0071] (2) A certain amount of sepiolite is ultrasonically dispersed in acetic acid solution at 100W for 1h, and then stirred at a stirring speed of 200r / min for 0.5h, wherein the mass ratio of sepiolite to acetic acid is 1:300;

[0072] (3) dissolving CTAB in water at 30°C, wherein the mass ratio of CTAB to water is 9:1000;

[0073] (4) Mix the solutions prepared in steps (1), (2) and (3), and stir at 40°C for 40min;

[0074] (5) Put the solution prepared in step (4) into a polytetrafluoroethylene reactor for solvothermal reaction, the solvothermal temperature is 160° C., and the solvothermal time is 24 hours. Obtain TiO with exposed 001 and 101 crystal planes 2 / Sepiolite Composite Gel.

[0075] The TiO that this embodimen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com