Method for preparing high-purity silica fume and application of silica fume

A micro-silicon fume, high-purity technology, applied in the direction of silicon oxide, silicon dioxide, coating, etc., can solve the problems of micro-silicon fume difficult to sell, low selling price, and high transportation and logistics costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

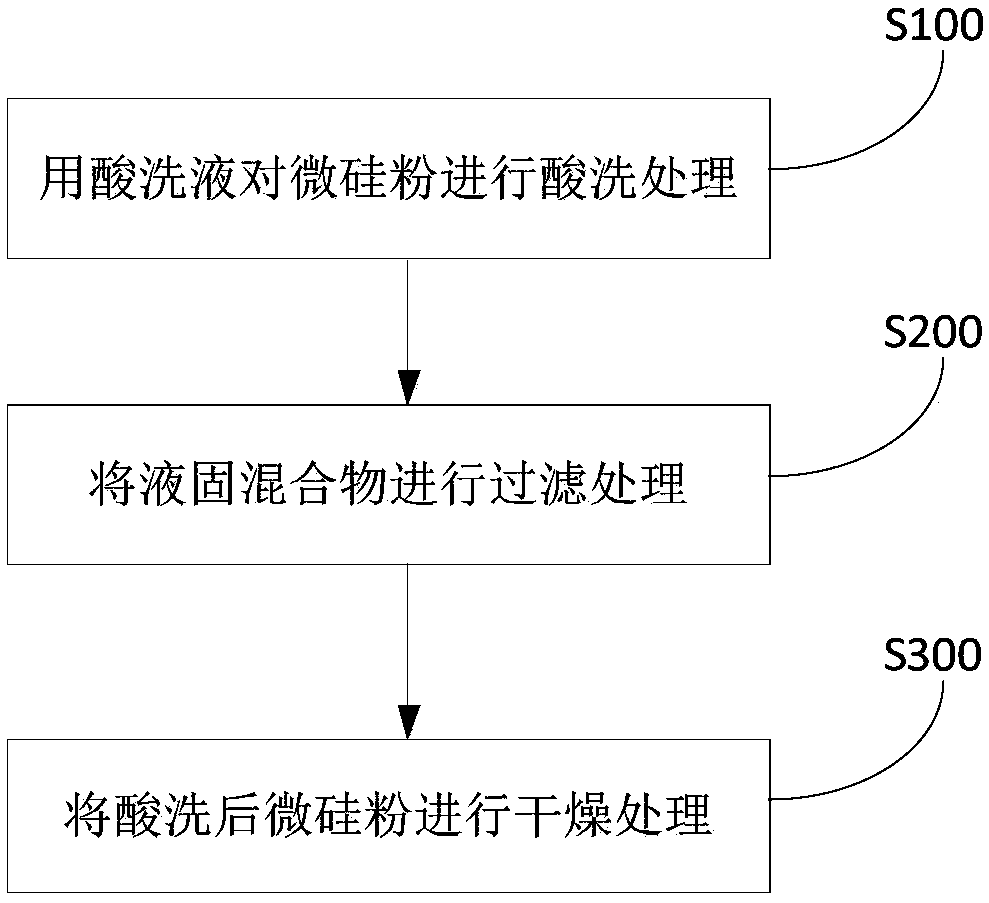

Method used

Image

Examples

Embodiment 1

[0037] Put the silica fume with a silicon dioxide content of 90wt% into the container, add dilute sulfuric acid with an acid content of 15g / L, adjust the solid-liquid ratio to 1:2, keep the temperature at 60 degrees Celsius, stir for 1 hour and then let it stand for 1- 2 hours; after standing still, the metal impurities in the silica fume are dissolved in the pickling solution, and the carbon contained in the silica fume floats on the upper layer at the same time, first remove the floating carbon, and then filter the silica fume after standing , during the filtration process, clean the silica fume with water for 1-3 times, so as to reduce the S content in the micro silica fume after pickling; finally put the filtered micro silica fume into an oven at 105 degrees Celsius to dry, dry Afterwards, it was finely ground with a vibrating mill, and the content of silicon dioxide obtained by sampling and testing was 96wt%.

Embodiment 2

[0039] Raise the temperature of the muffle furnace to a constant temperature of 650 degrees Celsius, then put the microsilica powder with a silica content of 90wt% into a corundum crucible, and put it into the muffle furnace for calcination for 1 hour; the calcined microsilica powder is cooled and tested , the carbon dioxide content is 96wt% and the whiteness is obviously improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com