Preparation method for greening brick from casting wastes and obtained greening brick

A technology of greening bricks and waste, applied in the field of greening bricks, can solve problems such as easy landslides, achieve the effects of improving strength, saving resources, and enhancing cohesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

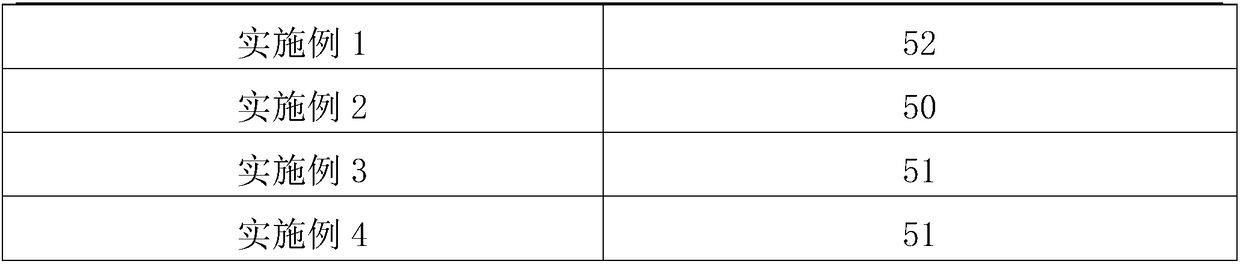

Embodiment 1

[0036] In this embodiment, the greening bricks made by casting waste are prepared through the following steps:

[0037] (1) Waste collection: pre-treat the waste slag and waste sand produced in the casting process. The pretreatment includes crushing the waste slag into particles of 8 mesh or less, screening and crushing the waste sand into particles of 8 mesh or less, and then The pretreated waste slag, waste sand and waste dust are collected for use;

[0038] (2) Batching embryo making: use the waste slag, waste sand, waste dust collected in step (1) with water glass, cement, phthalate plasticizer, resin binder, polycarboxylate superplasticizer and water The mixer pressurizes and mixes, and the pressure of the pressurized mixing is 480MPa. When the humidity of the mixture reaches 15%, use a molding machine to make a rectangular ordinary brick embryo with a standard size of 240×115×53mm;

[0039] (3) Curing: Soak the brick embryo in an aluminum chloride solution with a concentr...

Embodiment 2

[0044] In this embodiment, the greening bricks made by casting waste are prepared through the following steps:

[0045] (1) Waste collection: pre-treat the waste slag and waste sand produced in the casting process. The pretreatment includes crushing the waste slag into particles of 8 mesh or less, screening and crushing the waste sand into particles of 8 mesh or less, and then The pretreated waste slag, waste sand and waste dust are collected for use;

[0046] (2) Batching embryo making: the waste slag, waste sand, waste dust collected in step (1) and water glass, cement, epoxy plasticizer, resin binder, aliphatic high-efficiency water reducer and water are pressurized by a mixer Stir and mix, pressurize and stir with a pressure of 520MPa, when the humidity of the mixture reaches 10%, use a molding machine to make a trapezoidal brick embryo for mountain construction with a size standard of 250mm for the upper bottom, 450mm for the lower bottom, and 300mm in height;

[0047] (...

Embodiment 3

[0052] In this embodiment, the greening bricks made by casting waste are prepared through the following steps:

[0053] (1) Waste collection: pre-treat the waste slag and waste sand produced in the casting process. The pretreatment includes crushing the waste slag into particles of 8 mesh or less, screening and crushing the waste sand into particles of 8 mesh or less, and then The pretreated waste slag, waste sand and waste dust are collected for use;

[0054] (2) Batching embryo making: the waste slag, waste sand, waste dust collected in step (1) and water glass, cement, phthalate plasticizer, rubber binder, naphthalene series high-efficiency water reducer and water are used in a mixer Pressurized stirring and mixing, the pressure of pressurized stirring is 500MPa, when the humidity of the mixture reaches 12%, use a molding machine to make a square plate-shaped paving brick embryo with a size standard of 300×300×50mm and friction patterns on the brick body;

[0055] (3) Curi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com